In the world of industrial mixing, the Single Shaft Paddle Mixer really stands out because of its versatility. John Anderson, who’s basically a go-to guy for mixing tech at MixTech Solutions, says, “Picking the right mixer can really boost your process efficiency.” It just goes to show how important it is to choose the right equipment for your needs.

This type of mixer is designed to give you a pretty uniform mix of different materials. It’s pretty straightforward in terms of design but super effective, so it works well for a bunch of different applications. The paddle blades gently but thoroughly do their job, creating a mixing action that's just right. Of course, it’s important to think about what kind of material you’re working with — not every mixer is going to be perfect for every industry or situation.

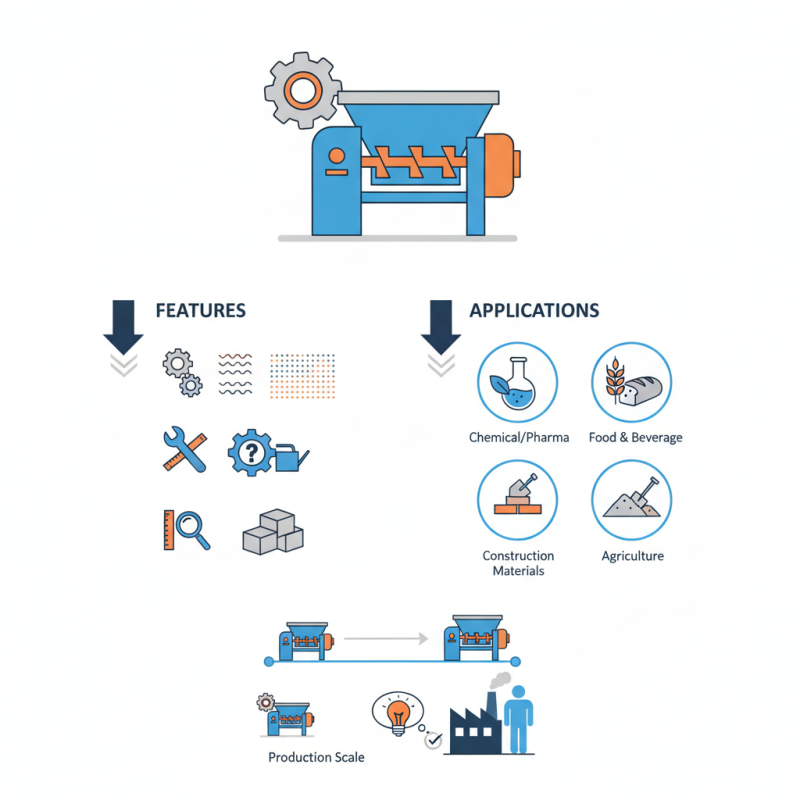

That said, it’s not all perfect. Some users have mentioned having a few issues when it comes to maintaining the mixer over time. Plus, size really matters — you need to find a model that matches your production scale. The right Single Shaft Paddle Mixer can definitely boost your productivity, but you’ve gotta pick the right size and features for your specific needs.

Single shaft paddle mixers play a significant role in various industries, including food processing, pharmaceuticals, and chemicals. These mixers are designed to blend materials efficiently, achieving a consistent product. They utilize a single shaft equipped with paddles that move in a circular motion, promoting thorough mixing. A key advantage of these mixers is their ability to handle both dry and wet materials, making them versatile for different applications.

Data from industry reports indicate that the demand for single shaft paddle mixers has grown by 15% over the last five years. This increase is attributed to their efficiency and reduced operational costs. Moreover, a Custom Single Shaft Paddle Mixer can be tailored to meet specific needs, optimizing performance for particular materials.

Properly designed paddles can enhance mixing uniformity, crucial for industries requiring precise formulations.

Tips: Regular maintenance is crucial. Keeping the paddles clean prevents contamination. Consider the material of the mixer; corrosion-resistant options may be necessary for certain applications. Don't overlook the importance of testing different configurations to improve mixing times. Balancing speed and force can significantly affect the outcome. Adjusting these parameters based on material characteristics ensures optimal performance and reduces waste.

Single shaft paddle mixers are designed for efficiency and versatility. They feature a robust frame and a rotating shaft with paddles that ensure uniform mixing. The paddles are spaced strategically to prevent material accumulation. This design allows for a consistent blend of materials in various applications, from food processing to chemical production.

One key feature is the ability to handle various viscosities. Whether dealing with dry powders or viscous pastes, these mixers can adapt. Many models are equipped with adjustable paddle speeds. This flexibility offers precise control over the mixing process. CE Certification Single Shaft Paddle Mixer models guarantee safety and compliance with industry standards.

Another aspect to consider is maintenance. While these mixers are relatively low-maintenance, regular checks are needed to ensure optimal function. Observing wear on paddles and the shaft can prevent larger issues. The need for occasional adjustment of paddle tension can be overlooked, yet it plays a crucial role. This highlights the importance of operator training and diligent care in prolonging mixer lifespan and performance.

| Feature | Description | Application |

|---|---|---|

| Efficient Mixing | Ensures uniform distribution of materials through intensive agitation. | Food and Beverage Processing |

| Customizable Paddle Design | Different paddle configurations available to suit specific mixing needs. | Chemical and Pharmaceutical Industries |

| High Durability | Built with robust materials to withstand intensive use. | Construction and Building Materials |

| Easy Cleaning and Maintenance | Designed for quick disassembly to facilitate cleaning without hassle. | Agricultural Products |

| Versatile Applications | Suitable for mixing a wide range of materials including powders, granules, and slurries. | Minerals and Mining |

Paddle mixers play a vital role in various industries. They are essential for processing a wide range of materials. Typical applications include food, pharmaceuticals, and building materials. Paddle mixers can efficiently blend wet and dry substances. They ensure homogeneity, which is crucial for product quality.

Common materials processed by paddle mixers include powders, granules, and pastes. For instance, in the food sector, they handle ingredients like flour, sugar, and spices. These ingredients often require precise blending for consistency. According to industry data, over 40% of food manufacturers use paddle mixers for their batching needs. The construction industry often blends cement, sand, and additives with paddle mixers, ensuring a well-mixed product.

Tip: Regular maintenance of paddle mixers enhances efficiency. Avoid overloading the mixer to prevent mechanical issues. Also, clean the equipment thoroughly after each use. This prevents cross-contamination of materials.

Despite their efficiency, paddle mixers have limitations. For some materials, the mixing time may be extended. Certain compositions may require additional processing methods for optimal results. Understanding the nuances of each material is essential for effective mixing. A well-informed approach leads to better product outcomes.

Single shaft paddle mixers play a crucial role in many industries. They are particularly valuable in food processing, pharmaceuticals, and chemical manufacturing. The versatility of a Single Shaft Mixerallows it to effectively blend materials with varying viscosities and densities. According to industry research, the global market for Industrial Mixers is projected to reach$5.6 billion by 2025, highlighting their importance across sectors.

In food processing, single shaft paddle mixers enhance the production of consistent products. They are used for dough, sauces, and powders. These mixers can accommodate a wide range of ingredients, ensuring uniform distribution. Research indicates that 45% of manufacturers prefer paddle mixers for their efficiency and ease of use. In the pharmaceutical industry, precision is critical. Single shaft mixers are used for creating uniform granulations and suspensions. This ensures that active ingredients are evenly distributed. The lack of proper mixing can lead to ineffective medications, underscoring the need for high-quality mixing solutions.

Challenges exist, though. Not all mixers are suitable for every application. Some may struggle with thicker materials, leading to inconsistencies. Moreover, maintenance is essential to prevent breakdowns. Regular inspections can address wear and tear but often get overlooked. This can impact productivity and cause delays. Thus, selecting the right single shaft mixer is key, as is ensuring it meets operational demands.

Single shaft paddle mixers are widely recognized for their versatility. They excel in blending powders, granules, and pastes. A recent industry report indicates that these mixers can achieve homogeneous mixtures in less than five minutes. This efficiency is crucial in industries like food processing and chemicals.

One primary advantage of using single shaft paddle mixers is their energy efficiency. According to a study, they consume up to 30% less energy compared to more complex mixer designs. This can significantly reduce operating costs. Additionally, their simple design allows for easy maintenance. Operators find less downtime when cleaning or repairing equipment.

Despite these benefits, challenges remain. For instance, achieving uniformity can sometimes be problematic with high-viscosity materials. Moreover, careful calibration is necessary to prevent over-mixing. That said, the overall benefits often outweigh these issues. The Single Mixer Machine continues to be a valuable tool in various sectors.

Single shaft paddle mixers are efficient and versatile tools in various industries. However, maintaining these mixers is crucial for optimal performance. Regular maintenance helps to avoid unexpected breakdowns and prolongs the life of the equipment.

Here are some tips to keep your mixer in top shape. First, check the paddle alignment. Misalignment can lead to uneven mixing and wear on components. Periodically inspect the mixing paddles for signs of wear. Any damage should be addressed promptly to prevent larger issues.

Another essential aspect is lubrication. Ensure that all moving parts are well-lubricated. Insufficient lubrication can cause overheating and increase wear. Schedule routine checks to replace worn bearings or seals. These simple actions can save costs in the long run.

Remember to document your maintenance practices. Keeping records helps identify patterns over time. This can guide future maintenance decisions.

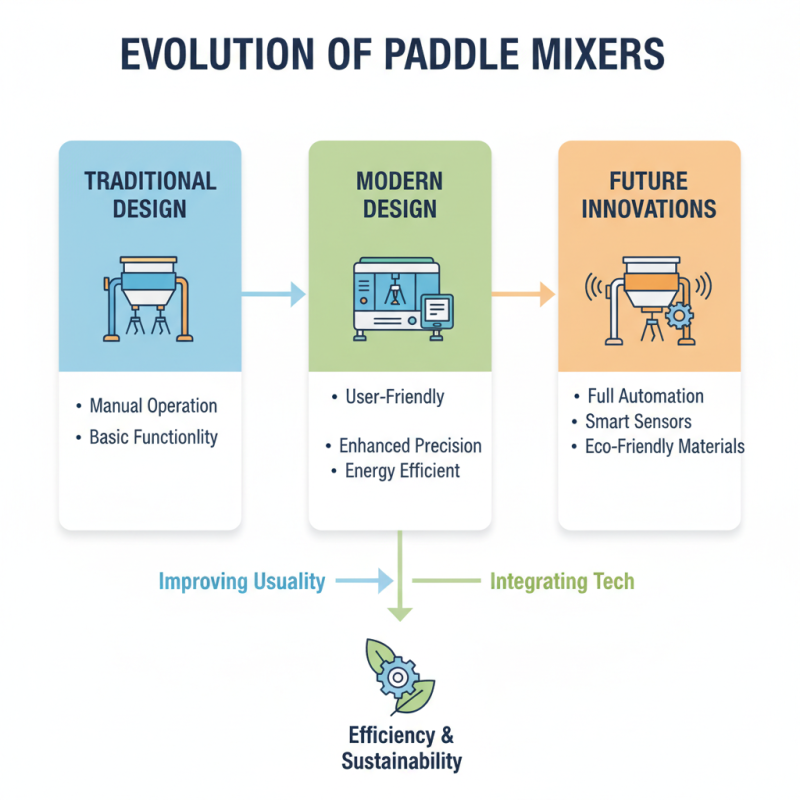

Paddle mixers are evolving rapidly. Their design is becoming more user-friendly, making them easier to operate. New technologies are being integrated, such as automation and smart sensors. These features can enhance efficiency and precision in mixing. The focus is shifting toward energy efficiency as well. Companies are looking for equipment that not only performs well but also saves energy.

The future of paddle mixers also involves improved materials. Lightweight yet durable materials are being developed. These can withstand harsh conditions while reducing overall weight. Increased versatility is another trend. Modern mixers can adjust to various materials and mixing requirements. This adaptability makes them suitable for different industries, including food, pharmaceuticals, and construction.

However, the industry must address challenges. Finding a balance between cost and cutting-edge features can be tricky. Some advanced features may come with a steep price tag. Additionally, training staff to understand new technologies is essential. Tech integration can lead to steep learning curves. Manufacturers must consider these factors while innovating.

The optimization of material mixing efficiency is a critical aspect in various industries, where achieving homogenous blends is essential for product quality. The High-Performance Conical Screw Belt Mixer offers an innovative approach to enhance mixing processes, leveraging advanced design principles to ensure superior performance. This mixer utilizes a unique conical screw configuration that promotes effective material flow and distribution, allowing for a consistent mixture while minimizing energy consumption.

Incorporating cutting-edge technology, the conical screw belt mixer stands out due to its robust design that marries functionality with efficiency. The screw and belt mechanism works harmoniously to facilitate the blending of materials, providing an excellent mixing effect that meets the varied demands of production. This innovative model is tailored to adapt to different materials, ensuring versatility and reliability in operations. By improving the mixing action and reducing process time, manufacturers can achieve higher productivity levels and better-quality end products, making this solution a preferred choice for industries focused on excellence in material handling.

: The article aims to provide valuable insights on various topics.

The content targets individuals interested in expanding their knowledge.

Readers can implement suggestions in everyday life to see improvements.

Yes, the article includes real-life scenarios that illustrate main points.

Regular revisits can reinforce understanding and encourage deeper reflection.

Reflection and seeking clarification can enhance comprehension.

The content is based on research conducted up until October 2023.

Yes, sharing insights promotes discussion and community learning.

Keep an open mind and be ready to re-evaluate your perspective.

Rushing through the content can lead to misunderstandings and missed details.

The article provides a comprehensive overview of Single Shaft Paddle Mixers, highlighting their key features, advantages, and applications across various industries. These mixers are designed to efficiently process multiple materials, making them versatile for tasks such as blending, mixing, and homogenizing. The discussion includes the types of materials that can be effectively handled, from powders to granules, and illustrates how Single Shaft Paddle Mixers are employed in sectors like food processing, pharmaceuticals, and construction.

Additionally, the article addresses maintenance tips to enhance the longevity and performance of these mixers, as well as future trends in paddle mixer technology that aim to improve efficiency and sustainability. Overall, the Single Shaft Paddle Mixer emerges as an essential piece of equipment, optimized for diverse mixing needs while offering significant operational benefits.