In the constantly changing world of food processing and pharmaceuticals, the role of a Solid Mixer really can’t be overstated. Recent industry reports show that companies using the latest solid mixing tech are seeing about a 25% boost in efficiency. I mean, this kind of innovation definitely helps simplify blending, but honestly, some manufacturers still find it tricky to pick the perfect solid mixer that fits their unique needs.

Dr. Emily Johnson from MixTech Solutions actually points out that this can be a big challenge. She says, 'Choosing the right solid mixer can really make or break your production quality.' That just goes to show how crucial it is to really understand what your specific requirements are when it comes to solid mixing. Lots of companies have run into problems with inconsistent blends, and honestly, they’re left wondering if they even picked the right equipment.

Even with all these recent advancements, there’s still no universal solution that suits everyone. Some mixers work like a charm, but let’s be real — not every system is a perfect fit for every application. Companies need to take a close look at their processes and figure out what actually works for them. Picking a solid mixer isn’t just about the latest gadgets; it’s about really understanding the ins and outs of solid mixing within your own production line.

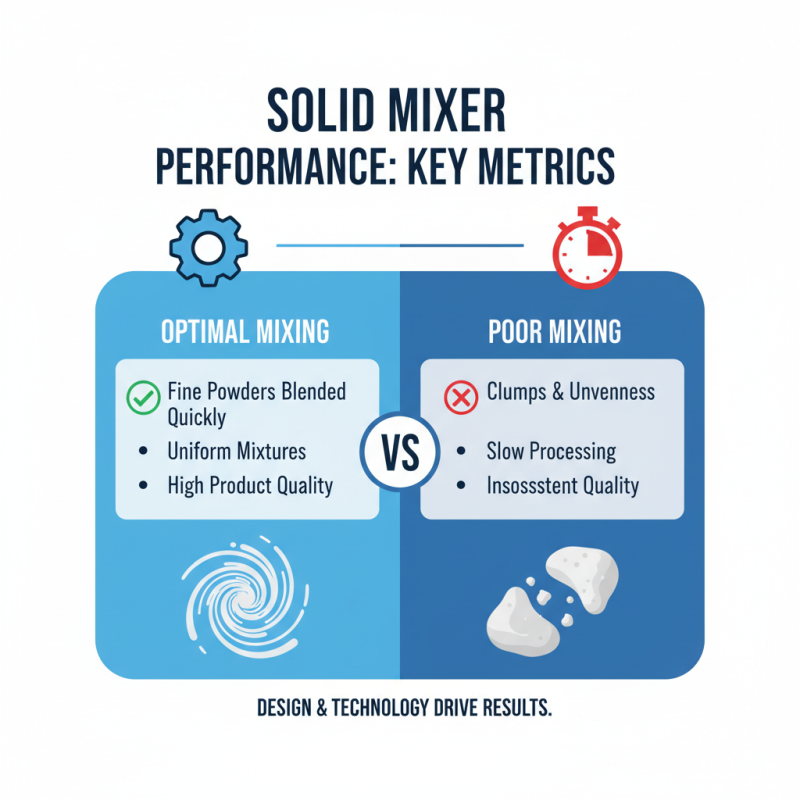

When it comes to achieving perfect mixing results, the choice of a solid mixer is crucial. The right equipment can significantly impact the quality of the final product. Solid Mixing Equipment helps ensure that every ingredient is blended thoroughly and uniformly. However, not all mixers are created equal. Some may leave behind clumps or uneven distributions, which can affect the taste or texture.

Depending on the materials being mixed, you may encounter challenges. For instance, fine powders might clump together, while larger granules may not mix well with smaller particles. It is essential to understand the material properties before selecting solid mixing equipment. Observing the mixing process is vital. Occasionally, you might notice that some areas are over-mixed while others are under-mixed. This inconsistency highlights the importance of proper equipment and mixing techniques.

Moreover, the user’s skill plays a critical role too. Even the best equipment cannot substitute for experience. Mistakes can lead to waste and dissatisfaction. Take the time to experiment with different solid mixers. Assess their performance, and don’t hesitate to adjust your technique. The pursuit of perfect mixing results is an ongoing journey, filled with trial and reflection.

In industrial applications, mixing uniformity is crucial. It ensures that every batch has the same quality and characteristics. Inconsistent mixing can lead to defects and wasted materials. This is where custom solid mixing equipment comes into play. It can help achieve a perfect blend of ingredients, but it’s not always foolproof.

Consider a situation where powders or pastes need to be combined. If the mixer lacks the right design, clumps may form, leading to uneven distribution. Instances of this can lead to significant losses in product quality. Unruly mixtures can result in costly recalls, impacting the company’s reputation. Therefore, investing in reliable Mixing Technology is essential.

However, even the best equipment requires careful monitoring. Regular maintenance is necessary to avoid breakdowns. Operators must also be trained to recognize signs of inadequate mixing. A seemingly simple process can become complex without proper oversight. To ensure optimal performance, it’s vital to continuously evaluate mixing processes and equipment effectiveness.

Choosing a solid mixer requires understanding key features that drive performance. One crucial aspect is mixing efficiency. A high-performance solid mixer should effectively blend materials with minimal effort. Research indicates that a mixer that achieves a uniform particle distribution can enhance product quality by up to 30%. This is critical in industries where precision matters.

Another essential feature is the mixer’s versatility. A robust solid mixer should handle various materials, including powders, granules, and pellets. Flexibility in design allows for easy adjustments based on material characteristics. Industry reports suggest that mixers equipped with variable speed settings yield better mixing results, often outperforming those with fixed settings. Users should expect occasional challenges, such as clumping or inconsistent mixing, highlighting the need for continuous evaluation.

Finally, the importance of safety standards cannot be overstated. CE Certification Solid Solid Mixing Equipment is vital. It ensures that a mixer meets European safety and environmental requirements. This certification increases trust in the equipment's reliability. Selecting a mixer without these certifications can lead to risks and inefficiencies. Consideration of these features can significantly impact mixing results over time.

When choosing a solid mixer, performance metrics are critical. Different mixers offer varied results based on their design and technology. For instance, some mixers excel in blending fine powders quickly. Others may struggle, leaving clumps or uneven mixtures behind. This inconsistency can affect product quality significantly.

Speed and power are vital factors. A high-speed mixer may provide quick results, but it can generate heat. This heat might alter the properties of certain materials. On the other hand, low-speed mixers tend to offer more thorough blending without overheating. However, they may take longer to achieve the desired results.

Material compatibility is another aspect to consider. Some mixers work better with specific materials while failing with others. This can lead to trial and error for users. Understanding a mixer’s strengths and weaknesses is essential for perfect results. The pursuit of a flawless mix is never-ending. Each experience serves as a learning opportunity, guiding future decisions.

Effective solid mixing is critical for achieving optimal results in various industries. Industry guidelines emphasize achieving homogeneity in mixtures, but real-life applications often present challenges. According to recent studies, achieving a mix uniformity of over 95% is ideal. Yet, many facilities report values as low as 80%. This disparity reveals a significant room for improvement and understanding in mixing processes.

When selecting a solid mixer, operators should consider several factors. The bulk density of components affects the efficiency of the mixing process. For instance, components with high-density contrasts may segregate, leading to inconsistent mixtures. Tips for better mixing include monitoring particle size distribution and moisture content. Both factors play a role in achieving desired homogeneity.

Mistakes in mixing often arise from inadequate equipment calibration. Regular maintenance of mixers is essential to avoid deviations in performance. Facilities must reflect on their mixing parameters and ensure they align with industry standards. Keeping a close eye on the mixing time and speed is crucial. Even small adjustments can lead to measurable improvements.

In various sectors, solid mixers play a critical role in achieving optimal mixing results. Factories producing pharmaceuticals rely heavily on precise solid mixing to ensure active ingredients are evenly distributed. A minor inconsistency can lead to ineffective medications. When working with powders, variations in particle size can complicate the process. Not all mixers handle this challenge with ease.

In the food industry, custom solid mixing improves product consistency. Imagine a bakery scaling up their production. Ensuring uniform distribution of ingredients is vital. However, a poorly calibrated mixer can result in uneven textures or flavors. This issue shows how crucial it is to choose the right equipment.

Case studies from the chemical sector reveal the complexity of solid mixing. A company struggled with a particular powder mix, leading to waste and increased costs. After redesigning their mixing process, they achieved more homogeneous results. However, they learned that even small adjustments require careful planning. Each sector demonstrates unique challenges in custom solid mixing, highlighting the importance of continuous improvement.

The future of mixing technology is bright, driven by innovative trends. As industries evolve, the demand for efficient mixing solutions has surged. Reports indicate that the global mixing equipment market is projected to reach $6 billion by 2025, reflecting a 4.5% annual growth rate. This growth underscores the critical role of advanced mixing technologies.

One noticeable trend is the incorporation of smart technology. Many mixers are now equipped with IoT capabilities. This allows for real-time monitoring and data collection. By analyzing mixing patterns, manufacturers can achieve more consistent results. However, integrating such complex technologies may introduce challenges in training staff effectively.

Sustainability is also becoming a priority. Many companies are looking to reduce energy consumption in their mixing processes. Reports show that energy-efficient mixers can save up to 30% more power compared to traditional models. Nevertheless, adapting to sustainable practices takes time and can be expensive initially. These are growing pains that industries must navigate. The evolution of mixing technology holds significant promise, yet it also requires careful consideration of the accompanying challenges.

| Mixer Type | Mixing Capacity (L) | Power (kW) | Speed (RPM) | Technological Features | Projected Growth in Demand (%) |

|---|---|---|---|---|---|

| Conical Mixer | 100 | 5 | 60 | High Efficiency, Low Shear | 15 |

| Ribbon Blender | 200 | 10 | 50 | Versatile Mixing, Adjustable Speed | 20 |

| Plough Mixer | 150 | 7 | 80 | Ultrasonic Control, Fast Mixing | 18 |

| Multi-Shaft Mixer | 300 | 15 | 90 | Intensive Mixing, Temperature Control | 25 |

| Planetary Mixer | 50 | 3 | 70 | 360° Mixing, Smart Control System | 12 |

The GP-SYJW series pull-type gravity-free mixer represents a significant advancement in mixing technology, tailored specifically for applications in the food industry. Its design focuses on maintaining high hygiene standards, making it ideal for food seasonings and prepared vegetable mixes. With an emphasis on easy and thorough cleaning, this mixer addresses the critical need for comprehensive sanitation in food processing. Its innovative pull-type mechanism enhances mixing efficiency and ensures a consistent blend of ingredients, which is essential for achieving superior product quality.

This cutting-edge mixer is not just a solution for large-scale food operations but is also a versatile tool for chefs and home cooks alike. Its gravity-free blending action allows for effortless mixing, saving time and reducing labor in any culinary setting. Users can expect unparalleled blending convenience, streamlining the preparation process and allowing for greater creativity in recipe development. In an era where efficiency is key, this mixer stands out by facilitating a smoother workflow and ensuring that ingredients are combined to perfection, ultimately enhancing the overall culinary experience.

: The product aims to improve everyday convenience. It enhances user experience through easy functionality.

To use it effectively, follow the provided guidelines. Practice makes perfect, so try different features.

If you encounter issues, reset the device. Check the manual for troubleshooting steps. This can help often.

Yes, avoid using it in wet conditions. Also, ensure proper ventilation during operation. Safety matters.

Absolutely, feedback is welcome. Share your thoughts through the designated channels. Your input is valuable.

A warranty is provided for certain defects. Ensure to read the terms carefully. Expectations can vary significantly.

The article "Best Solid Mixer for Perfect Mixing Results" delves into the critical role that mixing uniformity plays in various industrial applications. It emphasizes the need for high-performance solid mixers that ensure consistent results, highlighting key features such as efficiency, durability, and adaptability. A comparative analysis of popular solid mixers showcases their performance metrics, helping readers make informed decisions.

Additionally, the article outlines industry standards and guidelines essential for effective solid mixing. Through case studies, it presents successful implementations of solid mixers across different sectors, illustrating their impact on productivity and quality. Lastly, the piece looks ahead at future trends in mixing technology, noting innovative advancements that could shape the industry. Overall, the article serves as a comprehensive guide for selecting the best solid mixer to achieve optimal mixing results.