The Conical Powder Mixeris pretty special equipment. It does a great job at Blending Powders evenly and efficiently. You’ll see it popping up in lots of different industries — especially in food, pharmaceuticals, and chemical sectors.

One thing that really stands out about this mixer is its conical shape. Honestly, that design helps the powders move around more smoothly. When it’s running, the powders tumble and mix pretty quickly, which is a plus. But, I’ll be honest — getting that perfect, consistent blend isn’t always a walk in the park. Sometimes, you might run into clumping or uneven mixing, which can be a bit annoying.

Choosing the right size and model is super important when you’re picking out a Conical Powder Mixer. Not every one is perfect for every job. Each has its own pros and cons, so it’s worth spending some time to really understand what type you need. In the end, picking the right one can seriously boost your productivity and help you deliver a better quality product.

Overall, just take your time, do a bit of research, and you’ll find a mixer that fits your needs and makes your work a whole lot easier.

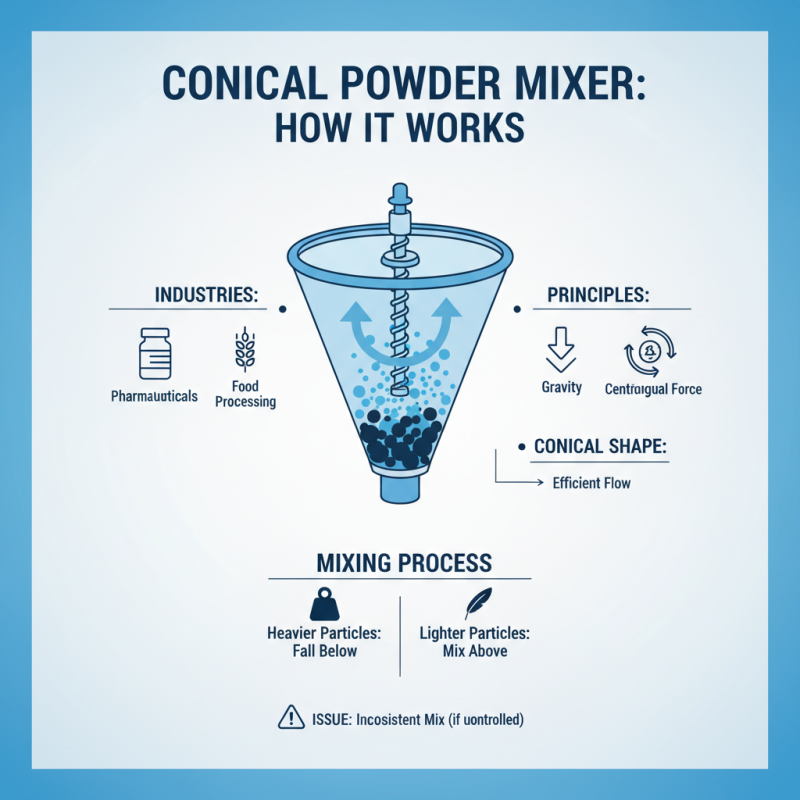

Conical powder mixers are specialized machines designed for blending powdered materials. They have a unique conical shape that facilitates even mixing. This design allows for efficient movement of powders, reducing segregation and ensuring uniformity. The mixing process mainly relies on gravity and the geometry of the mixer. As the powders are fed into the cone, they move towards the apex and then spread outwards, creating a thorough blend.

These mixers are widely used in various industries, including pharmaceuticals and food processing. The conical shape can accommodate different powder densities, promoting consistent mixtures. While they are effective, some challenges exist. Depending on the material's characteristics, achieving the desired blend may require adjustments in mixing time or speed. Occasionally, powders may clump together, leading to uneven distribution if not monitored.

Innovation continues in the field of powder blending. Improvements in design and technology aim to enhance efficiency and reduce errors. As industries seek better solutions, the evolution of conical powder mixers demonstrates the ongoing need for precision in manufacturing processes. Mixing may seem straightforward, but achieving the perfect blend remains a complex task.

| Feature | Description |

|---|---|

| Definition | A conical powder mixer is a type of equipment designed for blending powders and granules through a conical shape that enables effective mixing under gravity. |

| Working Principle | Materials are added to the mixer where the conical design promotes movement and mixing of powders as they cascade downwards. |

| Applications | Commonly used in pharmaceutical, food, and chemical industries for homogeneous blending of powders. |

| Advantages | High mixing efficiency, low energy consumption, Gentle Mixing action reduces particle damage. |

| Disadvantages | Limited to dry powders, potential for segregation if materials have vastly different densities. |

| Cleaning | Requires thorough cleaning to prevent cross-contamination between different batches. |

| Maintenance | Regular maintenance is necessary to ensure optimal performance and longevity of the mixer. |

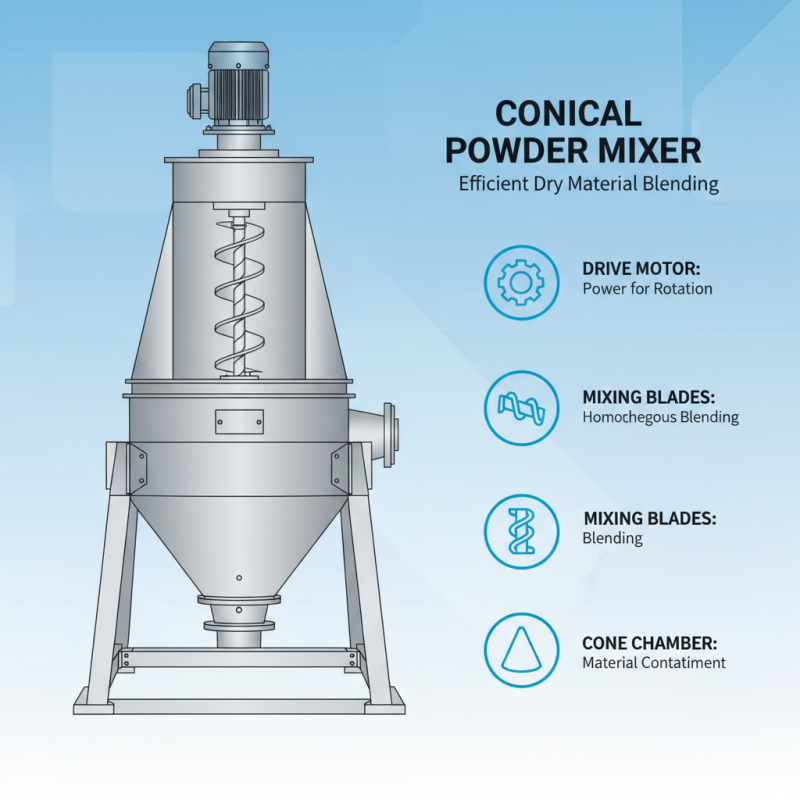

A conical powder mixer is a crucial tool in many industries. Its design allows for efficient mixing of powders, granules, and other dry materials. Key components of the mixer include the cone-shaped chamber, mixing blades, and the drive motor. Each part plays a role in the mixing process.

The cone-shaped chamber is essential for uniform mixing. It promotes movement by drawing material to the bottom. This design helps avoid clumps. However, operators must periodically inspect for wear or residue buildup. Mixing blades also vary. Some are straight, while others might be angled. Finding the right type could enhance mixing efficiency. Mixing blades can be a pain point, as incorrect selection leads to ineffective mixing.

Tips: Regular maintenance is key to prolonging mixer life. Always clean the chamber after use to prevent contamination. Pay attention to the size and shape of your materials for better mixing. The drive motor must be powerful enough for your workload. Understand its capacity to avoid overload.

Conical powder mixers are widely used in various industries, especially in pharmaceuticals and food processing. The working principle relies on gravity and centrifugal forces. The conical shape helps achieve efficient mixing by allowing powders to flow seamlessly. In this process, heavier particles fall to the bottom while lighter ones mix above them. This natural segregation can sometimes lead to inconsistent mixtures if not controlled properly.

Data from industry reports indicate that over 70% of manufacturers prioritize blending accuracy. When the cone's angle is not optimal, this can create dead zones. These areas may hinder the movement of powder, leading to uneven mixtures. Furthermore, the varying densities of materials can affect the mixing time. In some cases, adjustments in speed and duration are necessary to mitigate this issue.

Operators often face the challenge of achieving a homogenous blend. Even minor discrepancies can alter product quality significantly. Some studies suggest that a standard deviation in particle size can result in a 15% reduction in blending efficiency. Continuous monitoring and adjustment of process parameters are essential for maintaining consistency, but it often requires trial and improvement.

Conical powder mixers are increasingly popular in various industrial settings. They have unique shapes that enhance the mixing process. One significant advantage is their ability to prevent material segregation. This means that different particles maintain their integrity throughout the mixing. As a result, achieving a homogeneous blend becomes much easier.

Another benefit of using a Conical Mixer is the efficient use of space. These mixers often adopt a vertical design that saves room in production areas. This feature is essential for small facilities. Additionally, conical mixers can be scaled up or down easily. This adaptability helps businesses grow without major equipment changes.

However, there can be challenges. Not all materials mix perfectly. Some may require additional time or agitation. It’s crucial to assess the specific needs of your mix. With the right approach, a Conical Mixer can significantly enhance production efficiency. Recognizing its limitations is key for optimal use.

In various industries, the use of conical powder mixers has transformed blending processes. These mixers are particularly prominent in the pharmaceutical and food sectors. According to a recent report, the global powder processing market is valued at over $20 billion and is expected to grow steadily in the coming years. This growth is driven by the need for efficient and uniform mixing solutions.

Conical Screw Mixers excel in achieving homogeneous blends. They feature a specific design that allows for gentle mixing without damaging delicate powders. This is crucial in the pharmaceutical industry, where active ingredients must remain intact. Their versatility also makes them suitable for granular materials in the food industry. A survey found that 75% of food manufacturers prefer using conical mixers due to their efficiency.

Tips: When selecting a conical screw mixer, consider its capacity and material compatibility. Regular maintenance is vital to ensure consistent performance. Improper use can lead to uneven mixing, affecting product quality. Always consult with skilled operators to maximize the potential of your equipment. Continuous improvement in mixing techniques can lead to better outcomes. Over-reliance on technology can sometimes result in overlooked manual checks, which might pose risks.

Conical powder mixers are essential in various industries. Proper maintenance ensures smooth operation and longevity. Regular upkeep can save time and money.

One key maintenance tip is to inspect the mixer often. Check for wear and tear on blades and surfaces. Replace damaged parts immediately. This prevents further damage, which could lead to costly repairs later. Keeping the mixer clean is vital too. Residue buildup can affect mixing efficiency. Use appropriate cleaning agents that don’t damage the mixer materials.

Another aspect to consider is lubrication. Apply lubricant to moving parts regularly. This reduces friction and enhances performance. Ensure all seals are intact; a small leak can lead to powder contamination. Regularly reviewing these practices can lead to improved outcomes when using a Conical Ribbon Mixer. Stay attentive to small details. They can make a big difference in efficiency and safety.

When discussing powder mixers, the conical powder mixer stands out. It features a unique design where powders are blended at various angles. This method encourages a gentle mixing process, which is essential for fragile materials. The conical shape allows for effective gravity-assisted blending. However, it may not be as efficient for mixing large batches compared to other designs.

In contrast, ribbon mixers and paddle mixers have their advantages. They are known for side-to-side mixing. These machines can handle larger volumes, making them suitable for industrial applications. Yet, these designs can sometimes cause damage to delicate powders. The balance between efficiency and material preservation is a constant consideration for manufacturers.

The Conical Screw Mixer With Heating Jacket addresses specific needs. It combines gentle mixing with temperature control. This flexibility can be beneficial for certain applications. However, the equipment can be more complex and may require additional maintenance. Operators need to be aware of these factors when choosing the right mixer for their processes. The choice of a powder mixer ultimately hinges on the specific requirements of each application, highlighting the importance of careful design and operational consideration.

Integrating weighing systems in mixers and silos is crucial for enhancing material feeding control in various industrial applications. By incorporating three or four weighing modules at the bottom of the equipment's ear brackets, the system ensures accurate measurement and monitoring of materials as they are fed. The output from these modules is transferred to a junction box, which connects seamlessly with the weighing indicator. This setup allows for real-time tracking and adjustment of feed rates, enhancing operational efficiency.

The design of the weighing systems also offers flexibility in installation, allowing the enterprise standard indicator to be mounted on an embedded rail system inside the cabinet. For applications that require visibility or ease of access, the option to install the indicator on the cabinet door can be specified during the ordering process. With a precision capability of one part in one hundred thousand, these indicators ensure highly accurate material measurements, typically set for an accuracy of C3, or 1/3000, making them reliable for various production processes. By integrating such advanced weighing systems, facilities can optimize their material handling and enhance overall productivity.

: Daily exercise improves physical health. It enhances mental well-being too. Regular movement boosts energy.

Aim for at least eight glasses. Adjust this based on activity level. Listen to your body's signals.

Yes, home workouts can be effective. Use body weight or simple equipment. Consistency matters more than location.

Set realistic goals. Find activities you enjoy. Surround yourself with supportive people. Celebrate small successes.

Eat a light meal or snack. Focus on carbohydrates for energy. Avoid heavy foods that might cause discomfort.

Rest and hydrate well. Stretch to ease tension. Listen to your body to avoid overtraining injuries.

A Conical Powder Mixer is a specialized equipment designed to efficiently blend powders and granules through its unique conical shape. This type of mixer typically consists of key components such as a conical vessel, a mixing arm, and an outlet for the mixed product. The principle of operation centers around the gentle yet effective mixing action, which minimizes segregation and ensures uniformity, making it ideal for a variety of industries including pharmaceuticals, food processing, and chemical manufacturing.

The advantages of using Conical Powder Mixers include improved mixing efficiency, reduced processing time, and ease of maintenance. Their design allows for easy access for cleaning and inspection, contributing to better hygiene in sensitive applications. Furthermore, compared to other types of powder mixers, Conical Powder Mixers offer superior performance in terms of achieving a homogenous blend while minimizing the risk of damage to delicate particles. Proper maintenance, such as regular cleaning and inspection, is essential to prolong the lifespan and effectiveness of these mixers.