The Conical Screw Mixer is pretty much a game-changer in the blending world. Its clever design helps mix all kinds of materials effectively. The cone shape isn’t just for looks — it actually helps everything mix more evenly, and it reduces the risk of damaging the product. That’s why you’ll often see it being used in industries like pharmaceuticals, food production, and chemicals.

Getting the hang of how the Conical Screw Mixer works is really important. Basically, it uses a rotating screw to push materials through a cone-shaped chamber. This process guarantees that all the ingredients get mixed thoroughly. But, honestly, nailing that perfect, uniform mix can sometimes be tricky. Operators need to keep an eye on the mixing times and tweak things as needed — because different materials can behave quite differently.

The good news? It’s pretty efficient and can really speed up production. But, like any machinery, it needs to be handled with care. Over time, you might run into issues like wear and tear on the screw, so regular maintenance is a must to keep everything running smoothly. The more you understand about how it works, the better your results will be. So, companies should definitely invest some time in training staff — it makes all the difference in getting the most out of this awesome piece of equipment.

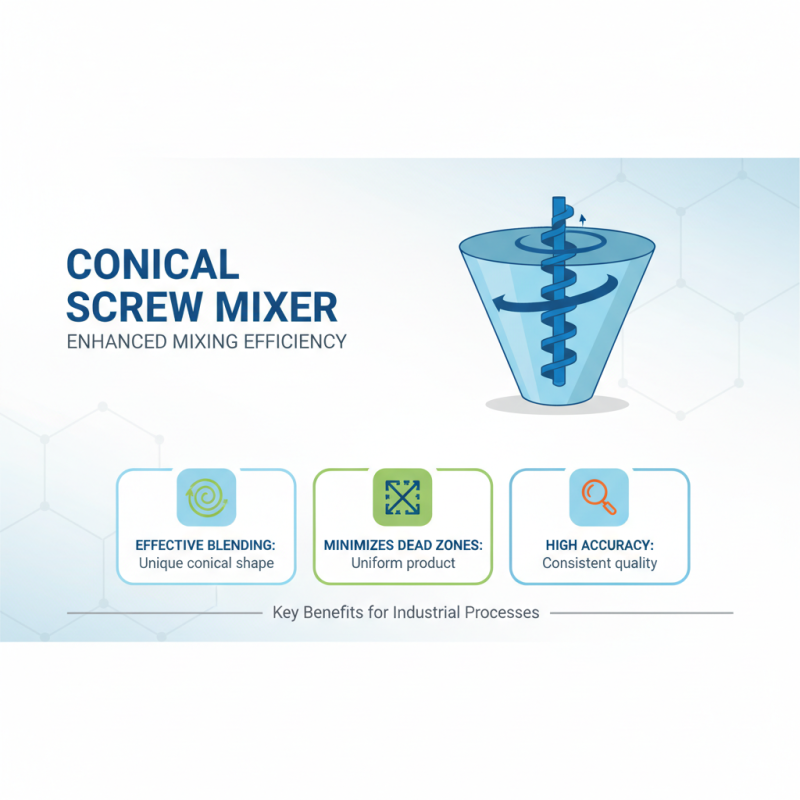

A conical screw mixer is a specialized piece of equipment designed for the mixing of powders, granules, and other bulk materials. Its unique shape allows for efficient blending of ingredients while minimizing dust and material segregation. The conical design facilitates both gravity and screw propulsion, enabling a thorough mix. It is ideal for industries such as pharmaceuticals, food processing, and plastics.

This mixer operates by utilizing a rotating screw within a conical chamber. As the screw turns, it moves materials upward along the cone's walls and then back down into the center. This process creates a continuous flow, promoting uniform distribution of ingredients. However, achieving the perfect mix can be challenging. Inconsistent feed rates or varying material densities can lead to uneven blending. Monitoring these factors is crucial for optimal performance.

Operators must also consider maintenance needs. The design may require regular cleaning and inspection to avoid contamination. While the conical screw mixer is efficient, understanding its limitations is essential. Proper training and process control can mitigate issues, ensuring a reliable mixing solution.

A conical screw mixer stands out due to its unique design. The shape allows for efficient mixing of various materials. Its conical design aids in better flow and distribution, which is crucial. This mixer features a rotating screw that moves materials gently yet thoroughly.

One of the notable aspects is the heating jacket. This feature provides precise temperature control during mixing. It keeps sensitive ingredients from degrading under heat. Operators must monitor this closely. Adjustments might be necessary to avoid overheating or uneven mixing. Balancing temperature and mixing efficiency is key.

Another design element is the discharge mechanism. The cone shape helps materials flow towards the outlet. However, sometimes, residues can be an issue. Operators should regularly check for build-up. This ensures consistent product quality and reduces downtime. With a Conical Screw Mixer With Heating Jacket, achieving uniformity in production becomes more manageable, but it still requires attention to detail.

A Conical Screw Mixer is designed for efficient blending and processing of materials. Its unique shape allows for effective mixing without excessive shear. At its core, the operation relies on a conical vessel that hosts a rotating screw. As the screw turns, it gently lifts and folds the materials, promoting uniformity.

The principle of operation revolves around the screw's geometry. The conical shape creates a natural flow pattern. Materials are pulled from the bottom and pushed toward the top, preventing dead spots. The design encourages uniform heat distribution, especially with a Conical Screw Mixer With Cooling Jacket. Adequate cooling minimizes the risk of heat-sensitive materials degrading during mixing.

However, achieving optimal mixing can be challenging. Factors like batch size and material properties can affect results. Sometimes, even a slight variation in the feed can lead to inconsistencies. Operators should monitor the process closely, ensuring that material is evenly distributed. This attention to detail is crucial for improving outcomes.

A conical screw mixer is designed for blending various materials. It offers numerous advantages that enhance operational efficiency. The unique conical shape allows for effective mixing. The design minimizes dead zones, ensuring product consistency. This quality is particularly important in processes requiring high accuracy.

One major advantage is versatility. Conical screw mixers can handle solid, liquid, and powdered materials with ease. This makes them suitable for diverse industries, including food and pharmaceuticals. Enhanced mixing speed is another benefit. The mixer can achieve homogeneity faster than traditional systems.

Tips: Regular maintenance is crucial. Check for wear on the mixing blades. This can impact efficiency over time. Additionally, consider your material properties before selecting a mixer. A Custom Conical Screw Mixer may be the right choice for specialized needs.

Another point to consider is energy consumption. While these mixers are efficient, improper use can lead to higher costs. Always refer to operational guidelines for optimal performance. Balancing load distribution during mixing is important, too. This practice ensures even blending and prevents uneven wear on equipment.

Conical screw mixers are versatile machines widely used in various industries. They efficiently blend dry powders, granules, and liquids. These mixers use a conical shape to facilitate both mixing and movement of materials. This unique design allows for better flow and reduces the likelihood of segregation.

In the food industry, these mixers are crucial for achieving homogeneous mixtures. They ensure that ingredients are evenly distributed. This uniformity is essential for maintaining quality and consistency. In pharmaceuticals, conical screw mixers play a vital role in drug formulation. Consistent mixing is required to ensure precise dosages.

Tips: Always monitor the mixer’s speed. An improper speed can lead to poor mixing. Additionally, ensure that the materials are fed consistently. Irregular feeding can cause uneven blending. Be mindful of the material types being used. Different materials may require adjustments in the mixing process.

In plastics and chemicals, these mixers enhance material properties. Proper mixing can improve product performance. However, it’s essential to assess the mixer’s capability for different materials. Some materials might clump together. Regularly check for these issues to avoid inconsistencies in production. Proper maintenance can mitigate many of these challenges.

Maintaining a conical screw mixer is essential for optimal performance. Regular inspections can prevent unexpected breakdowns. Check the seals and gaskets frequently to avoid leaks. Lubrication is key. Regularly greasing moving parts helps reduce friction. Without proper lubrication, the mixer may wear down quicker than expected.

Cleaning is another critical aspect. Residues can build up over time, affecting both functionality and hygiene. A thorough wash after each use ensures efficient mixing. Observing the cleanliness of the equipment is just as important. Failing to do so can lead to contamination, affecting product quality.

Operators should be trained and aware of common issues, such as unusual noises or vibrations. These signs can indicate underlying problems. Regular maintenance checks should be documented to track the condition of the equipment. Investing in a CE Certification Conical Screw Mixer means adhering to safety standards, but this alone doesn’t ensure longevity without care.

When comparing conical screw mixers to other types of mixers, it’s essential to consider their unique features. Conical screw mixers are known for their tapering shape, allowing for efficient mixing of materials. This design promotes uniformity, especially for powders and granulates. In contrast, traditional Ribbon Mixers may struggle with creating a homogeneous mix for certain materials.

Other mixers, like paddle or drum types, often have limitations in terms of versatility. They might not handle delicate ingredients well. Conical screw mixers excel in gentle mixing, which preserves the integrity of sensitive components. However, they may not be as effective for very large batches, making them less ideal for massive production scales.

Some mixers are simpler and cheaper but sacrifice quality in the final product. Conical screw mixers can require a higher investment and aren't always easy to clean. This can lead to waste if not managed properly. Users must reflect on their specific needs before making a decision. Every mixer has its strengths and weaknesses; understanding these can lead to better results in the long run.

| Mixer Type | Mixing Efficiency | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Conical Screw Mixer | High | Pharmaceuticals, Food Products, Chemicals | Gentle Mixing, Suitable for Fragile Materials | Higher Initial Cost |

| Ribbon Mixer | Medium | Powdered Food, Animal Feed, Chemicals | Cost-Effective, Easy to Clean | May Damage Fragile Particles |

| Planetary Mixer | High | Bakeries, Confectioneries, Cosmetics | Excellent for Heavy and Sticky Mixes | Can be Expensive, Bulk Size Limitations |

| Drum Mixer | Low | Construction Materials, Bulk Powders | Low Cost, Large Capacity | Inconsistent Mixing |

: The article aims to provide information on specific topics.

Anyone interested in the topic can find useful information.

Yes, some safety concerns are highlighted throughout the content.

The article discusses various aspects related to the subject matter.

Readers can gain insights to apply in real-life situations.

It's important to reflect on personal circumstances before acting.

Taking notes and summarizing key points can help retention.

Yes, the article includes specific examples to illustrate points.

Disagreements can lead to healthy discussions and reflections.

Yes, always consider potential changes in the subject matter.

A Conical Screw Mixer is a specialized mixing equipment designed to efficiently blend dry and wet materials within a conical vessel using a rotating screw mechanism. This unique design features a conical shape that facilitates the movement of ingredients, leading to uniform mixing without the risk of product degradation. The principle of operation revolves around the screw’s helix, which creates a gentle lifting and folding action, ensuring that all materials are thoroughly combined.

The advantages of using a Conical Screw Mixer include its ability to handle delicate products, achieving high-quality blends in shorter mixing times. Its applications span across various industries, including pharmaceuticals, food processing, and chemical manufacturing. Regular maintenance and care are essential to ensure optimal performance and longevity, while a comparison with other types of mixers highlights the Conical Screw Mixer’s efficiency and suitability for specific mixing tasks.