In the competitive manufacturing world, getting the right certifications isn’t just a box to check—it's pretty much essential if you want to succeed. Take, for example, a Manual Paddle Mixer. Making sure it meets CE standards isn’t just about ticking boxes; it’s a vital step that says a lot about product quality and, honestly, helps boost customer trust too.

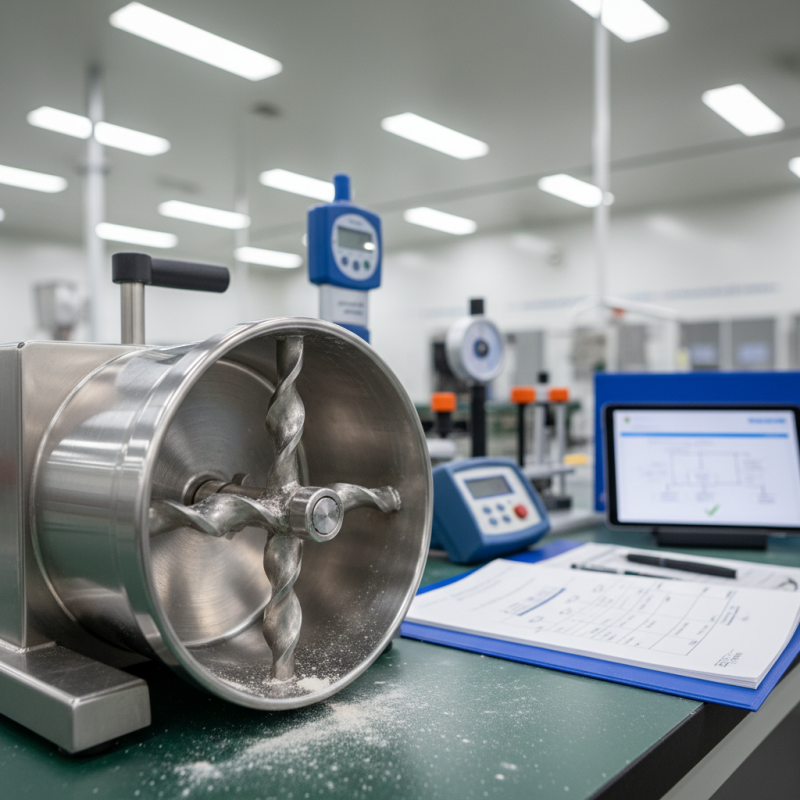

Manual Paddle Mixers are used across tons of industries, so sticking to safety and quality standards really isn’t optional. But here’s the thing—lots of manufacturers find the whole CE certification process pretty confusing and overwhelming. Figuring out what's required can feel like a lot. It’s really important to know how to run the right tests and keep proper records for your products.

Spending some time to wrap your head around CE certification definitely pays off in the long run. That said, let’s not pretend the process is always smooth sailing. Evolving standards mean companies are constantly having to adapt and improve their approaches. For folks making Manual Paddle Mixers, chasing that custom CE certification might just seriously change the game. Sure, the path might have its bumps, but honestly, the benefits make it worth it.

CE certification is vital for products in the European market. This compliance assures consumers of safety and quality. For Manual Paddle Mixer Products, understanding this certification is essential. It involves several steps, which can be overwhelming.

Manufacturers must first identify the relevant EU directives. These guidelines dictate testing and documentation. The process can be complex, especially if multiple regulations apply. Many manufacturers find this confusing. Preparing technical documentation is crucial. This should detail the product's design, function, and safety features. Missing details can delay certification.

Another challenge is the risk assessment. Conducting thorough evaluations helps identify potential hazards. Sometimes, manufacturers overlook this step, thinking it is unnecessary. Testing facilities are key to obtaining accurate results. The choice of a reliable lab impacts the certification timeline. Timely feedback is essential; waiting too long can stall sales plans. This is where many stumble. Understanding each requirement is vital for a smooth certification journey.

Achieving CE certification for Custom Manual Powder Mixer products involves understanding specific regulations and standards. This certification ensures that the products meet European safety and environmental requirements. According to a 2021 industry report, around 70% of manufacturers struggle with compliance due to the complex nature of these regulations.

The key standards typically involved include Machinery Directive 2006/42/EC and the Low Voltage Directive 2014/35/EU. These directives outline safety measures that manufacturers must follow. A thorough risk assessment is essential. Such assessments help identify potential hazards in product design. Additionally, compliance with EMC Directive 2014/30/EU is necessary for products that may cause electromagnetic interference.

**Tip:** Always maintain clear documentation throughout the design and manufacturing process. This documentation serves as evidence during the certification process. Engaging with third-party testing entities can also streamline your path toward certification.

Review relevant harmonized standards for your product. These standards provide benchmarks for safety and performance. A failure to adhere to established regulations can result in product recalls or fines. This might result from oversights in testing or incomplete documentation. Regularly updating knowledge on regulations is crucial for compliant production.

When pursuing CE certification for manual paddle mixers, meticulous documentation is essential. Begin by gathering technical files, which must outline your product's design, materials, and operation. Ensure the specifications meet European standards. This step can be daunting. Many manufacturers overlook vital details, leading to setbacks.

Next, compile risk assessments. These documents should identify potential hazards during use and demonstrate how you've addressed them. Without thorough assessments, your certification process could stall. Some companies find they missed critical points. This can be a learning opportunity to improve safety protocols.

Finally, keep a detailed record of quality control measures. Document every testing phase. This transparency is crucial for auditors. Also, don’t forget to include user manuals and installation guides. They provide essential information on safe operation. Remember, clarity in documentation will facilitate smoother communication with certification bodies. Facing challenges is part of growth in this process. Each mistake is a chance for improvement.

| Documentation Type | Description | Purpose | Estimated Time for Preparation |

|---|---|---|---|

| Technical File | Comprehensive documentation of the product design and manufacturing process. | Serves as the basis for demonstrating compliance with safety standards. | 4-6 weeks |

| Risk Assessment | Analysis identifying potential hazards associated with the product. | To ensure all risks are mitigated before product release. | 2-3 weeks |

| Declaration of Conformity | Document affirming that the product meets all applicable regulations. | Legally required for CE marking. | 1 week |

| Test Reports | Results from independent testing laboratories confirming compliance. | To validate product performance and safety under real-world conditions. | 3-4 weeks |

Conducting a risk assessment for manual paddle mixer products is essential for ensuring safety and compliance. This process identifies potential hazards associated with the equipment. It involves evaluating both the mechanical aspects and user interactions. An effective risk assessment should encompass various elements, including design flaws, operational hazards, and material safety.

Tips: Always involve team members in the risk assessment. Their insights can reveal overlooked issues. Create a checklist to guide your assessment, covering all critical areas.

In the assessment, consider the environment where mixers will be used. Dust, moisture, or extreme temperatures may influence safety. Ensure that protective measures are in place for users. Engage with operators to gather user experiences. This feedback may uncover risk factors not apparent during initial evaluations.

Tips: Document the assessment process meticulously. Use photographs and diagrams to illustrate risks. Regularly update the assessment as new information arises.

Engaging notified bodies is crucial for compliance assessment when obtaining CE certification for manual paddle mixer products. These entities help ensure that your mixers adhere to relevant European standards. The process can seem daunting. You must find a reputable notified body that specializes in mixing equipment. Each notified body has its own procedures and guidance.

The assessment involves comprehensive documentation. You will need technical files that showcase your product specifications and safety features. Additionally, quality control measures must be clearly outlined. Be prepared for potential questions about your manufacturing processes. Even minor details can become critical in the assessment. Some manufacturers overlook small aspects, which can lead to delays.

Communication with the notified body is essential. Keeping them informed can prevent misunderstandings. Also, it's vital to remain open to feedback. Sometimes, their requests may seem unnecessary. However, they are often based on past experiences. Consider this an opportunity for improvement. Your mixer may meet basic standards but could benefit from refinements.

Quality control in production is crucial for obtaining custom CE certification for manual paddle mixer products. Implementing effective measures ensures that every item meets required standards. This involves regular inspections and testing during various production phases. Each stage should have specific checkpoints to assess materials and workmanship.

Tips: Train your team regularly. They should understand the importance of quality checks. Utilize checklists to streamline the process. Small issues can lead to significant problems later on.

Documentation is vital in this context. Keeping precise records of each production batch helps in tracing any defects. If a product fails a test, it’s essential to analyze why. Was it a material flaw or a production error? Reflecting on these questions can improve future processes.

Tips: Conduct weekly review meetings. Discuss problems openly to foster a culture of continuous improvement. Encourage feedback from your team. Engaging them often leads to innovative solutions. Implementing these steps can ultimately lead to a smoother path to CE certification for manual powder mixer products.

When finalizing your product for CE compliance, consider crucial details for your Manual Mixing Machine. Marking is an essential step. Ensure your product meets the required standards. Each component must comply and be tested thoroughly. This helps avoid any future complications. Using clear, visible markings makes your compliance easily identifiable.

Additionally, documentation plays a vital role. Maintain records of testing, risk assessments, and compliance procedures. This demonstrates your commitment to safety and regulations. However, missteps can occur; missing documents can complicate the certification process. Regular audits are necessary to ensure everything is up to date.

Engage with a notified body if needed. Their expertise can guide you through complex regulations. They help you verify if your Manual Mixing Machine meets all safety and health standards. Don't underestimate these steps; they can save you from penalties or recalls. Reflect on each detail and stay proactive.

The CM Series Mixer stands out for its versatility and customization, making it an ideal solution for diverse blending needs. This continuous mixer is specifically designed to handle the simultaneous feeding and discharging of materials, which is a crucial feature for large-scale production lines. By enabling efficient continuous operation, it significantly enhances productivity while ensuring that materials are mixed evenly. This consistency in blending is vital for maintaining the quality and uniformity of the end product.

Moreover, the CM Series Mixer offers a range of customization options to cater to specific mixing requirements. Whether you are working with powders, granules, or pastes, this mixer can be tailored to meet your unique specifications. Its robust design not only promotes stability in the mixing process but also helps maintain the integrity and consistency of the materials being processed. This capability to adapt to various materials and production demands makes the CM Series Mixer an essential tool for any operation that prioritizes quality and efficiency in their blending processes.

: Begin with a clear goal. Outline your objectives and key steps to achieve them. Stay focused on your purpose.

Break tasks into smaller parts. Set deadlines for each part. Reward yourself after completing them.

Take a short break. Step outside for fresh air. Clear your mind with a calm activity.

Use a planner or app. Prioritize tasks based on urgency. Allocate specific time slots for each task.

Learn from them. Analyze what went wrong. Adjust your approach for future tasks.

Create a distraction-free workspace. Limit interruptions during work. Set specific goals for each session.

The article "2026 How to Obtain Custom CE Certification for Manual Paddle Mixer Products" provides a comprehensive guide to achieving CE certification for manual paddle mixers. It begins by explaining the importance of CE certification and the specific regulations and standards that apply to manual paddle mixer products.

The process involves preparing essential documentation, conducting a thorough risk assessment, and engaging with notified bodies for compliance assessment. Furthermore, it emphasizes the need for implementing robust quality control measures during production to ensure that products meet all safety and performance requirements. Finally, the article outlines the steps for finalizing the product and marking it for CE compliance, ensuring that manufacturers can confidently market their manual paddle mixers in compliance with European Union regulations.