In today's competitive market, securing CE certification for your Water Mixer Machine can be a challenging task. Many manufacturers overlook essential steps, leading to delays and costly mistakes. CE marking not only ensures compliance with European standards but also enhances product credibility. Companies like AquaMix Solutions know the importance of a well-prepared certification process.

Understanding the key requirements is crucial. For instance, thorough documentation and testing are vital. Common pitfalls include inadequate technical files and insufficient risk assessments. A Water Mixer Machine must meet specific guidelines to achieve compliance. This can feel overwhelming for new manufacturers, but attention to detail will pay off.

Moreover, staying updated on regulations is essential. Standards evolve and keeping pace can be a struggle. Many businesses fail to adapt, resulting in failed certifications. Ultimately, each step taken towards compliance is an investment in your Water Mixer Machine's future success. This journey may be fraught with challenges, but it’s also an opportunity for growth and improvement. Embrace the process, and your efforts will be rewarded.

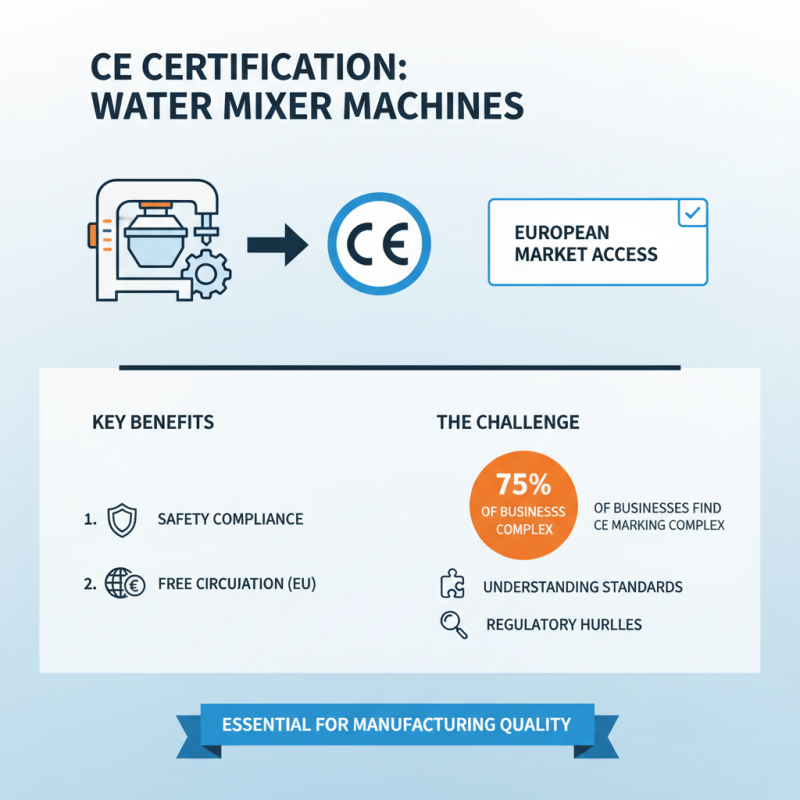

CE certification is vital for manufacturing Custom Water Mixer Machines. The process ensures that products comply with safety standards within the European market. According to a report from the European Commission, about 75% of businesses face hurdles in understanding CE marking requirements. This statistic highlights the complexity of the standards set forth.

Understanding the directives is crucial. Water mixer machines often fall under the Machinery Directive and the Low Voltage Directive. Missing or misinterpreting these regulations can lead to costly delays. In 2022, a study revealed that companies without proper CE certification faced fines averaging €50,000. What happens when manufacturers overlook crucial details in documentation? It creates significant setbacks and undermines market trust.

Design testing is essential when developing a custom water mixer machine. Testing can cover various aspects, including safety and performance. Around 40% of water mixer machine failures stem from inadequate testing protocols. Without thorough assessments, manufacturers risk releasing problematic products. It's a reminder that diligence in the CE certification process is not just regulatory but vital for overall success.

When designing a water mixer machine, ensuring CE certification is essential. Compliance starts with identifying the necessary components. Key areas include electrical safety, mechanical stability, and hygiene measures. Each part should meet specific standards to pass inspections reliably. Regular testing of materials can reveal hidden issues.

Make sure to detail how components interact. Gaps in documentation can lead to failure. For example, improper sealing can pose health risks. Overlooked factors may delay the certification process. It's vital to address these concerns proactively. Examine your design frequently to eliminate oversights. This self-critique ensures you remain on track for CE certification.

Choosing the right components is tricky. Not all materials meet compliance for CE certification. Testing and validation are ongoing tasks. Sometimes, suppliers may not fully understand these requirements. Establishing clear communication with them is crucial. After all, a mistake in sourcing can compromise the whole certification. Aim for transparency and thoroughness to achieve reliable results in CE Certification Water Mixer Machine products.

When designing water mixer machines, conducting risk assessments is crucial. Identifying potential hazards helps ensure safety standards are met. Start by evaluating components like pumps and valves. Are they susceptible to leaks or failures? Each part must be analyzed.

Think about the environment where the machine will be used. Will it operate in high temperatures or wet conditions? Assessing these factors is essential. Consider user interaction with the machine. Could someone accidentally touch a hot surface? Risks increase in busy environments.

Document every finding from your assessment. This step may seem tedious, but it is vital. Review and reflect on the risks regularly. Are there new safety measures you could implement? Continuous improvement is key to achieving safety compliance.

Documenting technical files is crucial for the CE certification of Water Mixing Machineproducts. These documents provide evidence that the product meets safety and performance standards. Start with a comprehensive risk assessment. Identify potential hazards associated with the Water Mixing Machine. Include user instructions that describe safe operation practices.

Next, ensure your technical files contain product design specifications. Detail the materials used in the water mixing machine and the manufacturing processes involved. Testing results must also be included. Provide clear information on how these tests verify compliance with directives. Be open about any challenges faced during testing. Note any failures and improvements made to resolve them.

Also, consider the importance of maintenance and troubleshooting guides. These are often overlooked but vital for long-term product safety. Documenting these guides clearly shows commitment to user safety. Review your technical file periodically. This practice ensures it remains current and aligned with evolving regulations. Aim for clarity and precision, while also acknowledging areas that may still need improvement.

Ensuring product compliance with EU regulations is crucial for manufacturers of water mixer machines. The European market demands strict adherence to safety and performance standards. According to a recent report, 70% of non-compliant products fail safety testing. These failures can lead to costly recalls and legal issues.

Testing and verification begin in the early stages of product development. Manufacturers must document each step of the design process. This involves rigorous material selection and performance testing under various conditions. Industry experts suggest that over 60% of compliance issues arise from inadequate testing protocols. Often, manufacturers rush the verification process, leading to oversight and costly mistakes.

Regular audits can help identify gaps in compliance. A thorough evaluation of standards such as the Machinery Directive is essential. Studies indicate that consistent testing can reduce compliance failures by nearly 40%. It’s important to invest in the right testing equipment and personnel. Achieving compliance is not just about meeting regulations; it also builds customer trust and enhances market reputation.

When it comes to meeting CE certification for water mixer machines, proper labeling is crucial. CE marking is a mandatory conformity marking for products sold in the European Economic Area. According to a report by the European Commission, up to 25% of products fail compliance checks due to improper labeling. This highlights the need for clear guidance in labeling practices.

Documentation is another significant factor. Manufacturers must gather technical files that outline product specifications, testing methods, and safety assessments. A detailed study indicates that 30% of manufacturers lack adequate documentation for CE certification. This gap can lead to costly delays or even market rejections. Compliance with documentation practices ensures transparency and builds trust with consumers and regulatory bodies.

Missteps in CE marking can lead to severe ramifications. Companies may face financial penalties or product recalls. It's essential to pay attention to each detail in the labeling process. Clear identification, country of origin, and applicable standards are vital. Companies must reflect on their practices to minimize errors. The certification journey is intricate; overlooking documentation may prove damaging.

| Tip No. | Tip Description | Documentation Required | Best Practices |

|---|---|---|---|

| 1 | Understand CE marking prerequisites | CE marking guidelines | Review the EU directives |

| 2 | Conduct risk assessments | Risk assessment report | Use standardized methods |

| 3 | Ensure compliance with relevant standards | Relevant standards documentation | Stay updated with changes |

| 4 | Prepare technical documentation | Technical files | Maintain organized records |

| 5 | Create a Declaration of Conformity | Declaration template | Involve all stakeholders |

| 6 | Label your products correctly | Labeling specifications | Follow design guidelines |

| 7 | Use appropriate symbols | Symbol library | Ensure symbols meet EU regulations |

| 8 | Stay informed on updates | Regulatory updates | Subscribe to industry news |

| 9 | Conduct regular audits | Audit reports | Implement corrective actions |

| 10 | Consult with a professional | Consultation records | Choose reputable experts |

Achieving CE certification for Custom Water Mixing Machine products can be challenging. Many manufacturers encounter non-compliance issues during the certification process. According to recent industry reports, about 30% of devices fail initial CE audits due to documentation gaps. Without proper technical documentation, manufacturers may struggle to prove compliance with the relevant European standards.

Common pitfalls involve insufficient risk assessments and inadequate testing protocols. It is essential to ensure that your product undergoes thorough testing before submission. Failing to meet safety and performance standards can lead to costly delays. In a study by the European Machinery Directive, non-compliance could range from fines to mandatory recalls. This underscores the importance of meticulous preparation.

Many manufacturers overlook labeling requirements. Clear, compliant labeling is vital. Mislabeling can derail the certification process entirely. Also, consider enaging with experts early on. Their insights could help identify potential weaknesses in your design or production processes. Overcoming these challenges is crucial for successful certification of Custom Water Mixing Machine products.

The exploration of industrial double shaft paddle mixers has gained significant attention in modern manufacturing due to their efficiency and versatility. These advanced mixing machines, particularly the SYJW series, are designed to handle a diverse range of materials, especially those with large discrepancies in specific gravity and other physical characteristics. This capability makes them an ideal choice for industries requiring precise and uniform mixing of raw materials.

A standout feature of double shaft paddle mixers is their ability to accommodate various material properties, such as fineness and fluidity. The design allows for thorough mixing without the risk of weight segregation, which is often a challenge with standard mixing techniques. As a result, manufacturers can achieve consistent product quality, which is crucial in sectors like pharmaceuticals, food processing, and chemicals, where material homogeneity directly affects production outcomes.

Furthermore, the adaptability of these mixers enables them to handle both dry and wet materials, making them suitable for a broad range of applications. Their effectiveness not only streamlines production processes but also enhances operational efficiency, making them an invaluable asset in modern manufacturing setups. The evolution of industrial mixing technologies, specifically the double shaft paddle mixer, showcases the industry's commitment to continuous improvement and innovation in tackling complex manufacturing challenges.

: The product aims to enhance daily routines. It provides practical solutions for common issues.

Follow the provided instructions carefully. Take note of specific guidelines for optimal results.

Yes, it is designed for various settings. Consider the surrounding conditions before use.

Refer to the troubleshooting section. If problems persist, contact support for assistance.

Regular cleaning is recommended. Check for wear and tear periodically to ensure longevity.

The product is intended for adults. Parental supervision is advised for younger users.

You may need to reassess usage. Feedback can help identify areas for improvement.

It may not be the best choice for everyone. Evaluate your needs and preferences carefully.

Some retailers offer demonstrations. Ask about options available at your local store.

It is made from durable materials, yet specifics may vary. Check the details for more information.

Achieving CE certification for Water Mixer Machines is essential for ensuring compliance with European safety and environmental standards. The process begins with a thorough understanding of CE certification requirements, which includes identifying the essential components necessary for compliance during product design. Conducting risk assessments is crucial to evaluate safety standards and mitigate potential hazards associated with Water Mixer Machines.

In addition to these preliminary steps, documenting technical files with key elements is vital for demonstrating compliance. Testing and verification processes must be carried out to ensure products meet EU regulations, while proper labeling practices, including accurate CE marking, are necessary for legal compliance. By being aware of common non-compliance issues, manufacturers can proactively address potential pitfalls during the certification process, ultimately ensuring that their Water Mixer Machines are safe and market-ready.