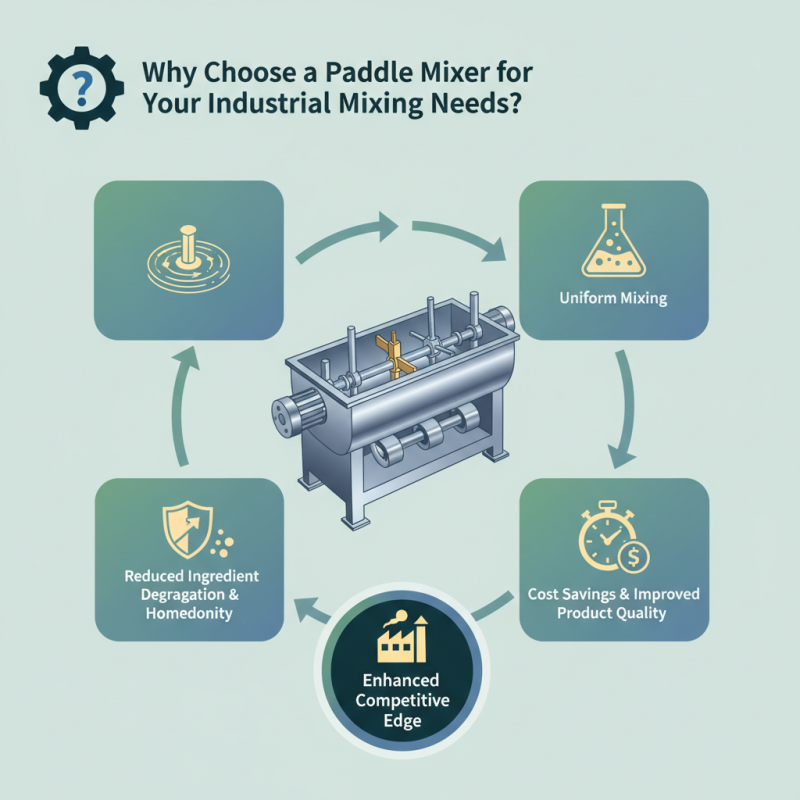

In the ever-changing world of industrial mixing, choosing the right equipment really makes all the difference if you want top-notch results. As Dr. John Smith, a well-known expert in this field, puts it, “A Paddle Mixer isn’t just any machine — it’s a key player in boosting process efficiency and keeping product quality steady.” That genuinely highlights how important Paddle Mixers are across a bunch of industries, whether it’s food, pharma, construction materials, or chemicals.

Paddle Mixers are pretty much the Swiss Army knives of mixing—they handle powders, granules, pastes, you name it. Their clever design allows them to mix gently but effectively, which helps prevent ingredients from breaking down while making sure everything is evenly mixed. Because they can work with all kinds of materials and give you pretty tight control over the process, Paddle Mixers are often the go-to choice for manufacturers who want reliable and efficient results.

Getting a Paddle Mixer isn’t just about speeding up production; it’s also about saving money and making your product better. When you’ve got the right setup, you’ll find it easier to stay competitive in this busy market. As industries keep evolving, the Paddle Mixer remains a vital piece of the puzzle for achieving those perfect mixes every time.

Paddle mixers have gained popularity in industrial settings due to their effective design and versatile performance. These mixers are characterized by their unique paddle-shaped blades that rotate to create a gentle yet efficient mixing action. This design allows for thorough blending of materials, ensuring uniformity in the final product. Additionally, paddle mixers can handle a variety of materials, from dry powders to viscous pastes, making them suitable for a wide range of applications in industries such as food processing, pharmaceuticals, and chemical manufacturing.

When selecting a paddle mixer, it’s crucial to consider the size and layout of your mixing chamber. A well-designed mixing chamber enhances the mixer’s efficiency by minimizing dead zones where materials may not blend properly. Furthermore, the choice of paddle configuration can significantly impact mixing performance. Opting for adjustable or interchangeable paddles allows for customization based on material characteristics, aiding in achieving the desired consistency and quality.

**Tips:** Ensure that the mixer’s speed and paddle design align with the specific properties of the materials you are working with. Experimenting with different paddle angles can also improve mixing efficiency. Regular maintenance and cleaning of your paddle mixer contribute to prolonged lifespan and consistent mixing results.

Paddle mixers have gained significant traction in various industrial applications due to their unique design and operational efficiency. According to a report by Industry Research, the global market for Industrial Mixers is expected to reach $9.4 billion by 2026, with paddle mixers anticipated to account for a substantial segment of this growth. Their ability to handle a wide range of materials—whether dry, wet, or in paste form—makes them an essential choice for industries such as food processing, pharmaceuticals, and chemicals.

One major advantage of paddle mixers is their effective blending capabilities. Their specially designed paddles create a shearing action that ensures uniformity in the final product, which is critical in quality-sensitive operations. A study published in the Chemical Engineering Journal highlights that paddle mixers can achieve mixing times that are up to 50% faster than traditional Mixing Equipment, significantly enhancing production efficiency. Additionally, the compact design of paddle mixers allows for easy integration into existing production lines, minimizing disruptions and facilitating smoother transitions in manufacturing processes. This versatility is further emphasized by the growing preference among manufacturers for equipment that can adapt to varying batch sizes and compositions, reflecting the dynamic nature of modern industrial demands.

Paddle mixers are increasingly favored across various industries due to their efficiency and versatility in handling a diverse range of materials. One key sector that benefits from paddle mixing technology is the food industry. In this realm, paddle mixers facilitate the blending of ingredients for baked goods, sauces, and dry mixes, ensuring uniform consistency and enhancing product quality. They are particularly adept at combining powders and liquids, which is essential for creating stable emulsions and suspensions necessary for food processing.

Another significant industry that leverages paddle mixers is the chemical sector. These mixers are particularly effective in mixing viscous materials, such as pastes and slurries, which are commonplace in chemical manufacturing. The ability to maintain homogeneity while minimizing shear forces makes paddle mixers ideal for sensitive formulations. Additionally, paddle mixing technology is also prevalent in the construction industry, where it is used to blend cement, sand, and aggregates for concrete production, enhancing the efficiency and quality of construction materials. This versatility across key industries highlights the importance of paddle mixers in optimizing production processes and ensuring high-quality outputs.

When it comes to industrial mixing, there are various types of mixers available, each suited for specific applications. Paddle mixers, known for their versatility and efficiency, stand out when compared to other mixer types like ribbon or blade mixers. Paddle mixers operate by using a set of paddles that rotate within the mixing chamber, gently stirring and blending materials. This design is particularly effective for achieving homogeneity in viscous or dense products, which may be challenging for other mixers.

In contrast, ribbon mixers utilize a helical ribbon that moves materials in a more aggressive manner, which can lead to shear and potential damage to fragile components. While ribbon mixers are excellent for dry powders and granular materials, they may not provide the same care in blending that paddle mixers can offer. On the other hand, blade mixers, although effective for liquids and light materials, might struggle with the uniform mixing of heavier bulk ingredients. Paddle mixers provide a balanced approach, making them particularly advantageous for industries requiring a gentle yet thorough mixing process, such as food production or pharmaceuticals. Their ability to handle a variety of materials, from powders to slurries, sets them apart in the world of industrial mixers.

When selecting a paddle mixer for industrial applications, it's essential to consider the specific requirements of your mixing process. Paddle mixers are versatile, making them suitable for various materials, including powders, granules, and slurries. One of the key factors to assess is the equipment's capacity. Understanding the volume of material you need to mix will help determine the size and power of the paddle mixer.

Additionally, you should evaluate the material compatibility with the mixer’s construction, ensuring that it can handle the abrasiveness or chemical nature of the substances involved.

Another important aspect is the paddle design and configuration. Different applications may require varying paddle shapes, sizes, and arrangements to achieve optimal mixing efficiency. For instance, a paddle mixer with a wider spacing between paddles might be more effective for bulk materials, while a tighter arrangement may be suited for finer powders.

Consideration of the mixing time required for your materials is also crucial. The right paddle mixer not only enhances product uniformity but can also reduce processing times, leading to increased productivity in your facility. By assessing these factors, you can ensure that you choose the most appropriate paddle mixer to meet your specific industrial mixing needs.

When it comes to ensuring the longevity of your paddle mixer, proper maintenance is crucial. Regular inspections and timely servicing can significantly enhance the lifespan of the equipment, which is vital given that industrial mixing systems account for approximately 30% of operational costs in manufacturing processes. According to the 2022 Mixing Technology Report, failure to maintain mixer components can lead to unplanned downtime, with costs potentially reaching thousands of dollars per hour for lost production.

To maintain a paddle mixer effectively, it is essential to conduct regular cleaning and lubrication of the mixing blades and bearings. A study published by the International Journal of Industrial Engineering highlights that routine lubrication not only reduces friction but also prevents wear and tear, extending the mixer’s operational life by up to 25%. Furthermore, operators should ensure that the mixer is calibrated correctly to avoid unnecessary strain on the motor, which can cause overheating and premature failure. Regularly scheduled inspections can lead to early detection of any irregularities, promoting a proactive approach to equipment management and ensuring sustained productivity in the mixing process.

Paddle mixers are increasingly becoming the go-to solution in various industries due to their versatility and efficiency in handling a wide range of materials. These mixers are particularly effective for blending semi-solid and pasty substances, which makes them ideal for applications in the food, chemical, and pharmaceutical sectors. According to a report by MarketsandMarkets, the global paddle mixer market is projected to grow at a CAGR of 5.6% from 2021 to 2026, driven by the rising demand for processed foods and increasing automation in manufacturing processes.

In the food industry, paddle mixers are commonly used for blending dry ingredients, such as flour, sugar, and spices, as well as for preparing doughs and batters. The design of paddle mixers allows for both gentle and thorough mixing, which is crucial for achieving consistent product quality. Similarly, in the chemical industry, they are effective for mixing polymers, resins, and other viscous materials, ensuring homogeneity and optimal reaction conditions. Furthermore, in the pharmaceutical sector, paddle mixers facilitate the mixing of active ingredients with excipients, which is essential for manufacturing tablets and other dosage forms.

With their ability to handle a variety of materials such as powders, granulates, and slurries, paddle mixers demonstrate significant adaptability. They are particularly beneficial for materials that require specific shear forces or where bulk density is a concern. As manufacturers continue to demand more efficient and reliable mixing solutions, the paddle mixer stands out as a key player in addressing the challenges associated with complex material processing needs across different industries.

Industrial double shaft paddle mixers play a crucial role in enhancing efficiency across various sectors, particularly in industries that handle materials with significant variations in physical properties. The SYJW series of double shaft paddle mixers, recognized for their advanced design, effectively address the challenges posed by materials with disparate specific gravities, fineness levels, and fluidity. This mixer type excels in creating homogeneous mixtures, which is essential for processes in sectors such as chemicals, food production, and pharmaceuticals.

According to industry reports, the global market for industrial mixers is projected to grow at a CAGR of about 5.2% over the next several years, driven by the demand for efficient mixing solutions that can accommodate diverse material characteristics. The double shaft paddle mixer, in this context, stands out for its ability to minimize segregation and achieve uniformity, making it an invaluable asset for manufacturers looking to ensure product quality and consistency. With its robust design, the SYJW series can handle varying batch sizes and is particularly beneficial in applications involving heavy and light particles mixed together, further emphasizing its versatility.

Further enhancing efficiency, double shaft paddle mixers like the SYJW series operate with a lower energy consumption level compared to traditional mixers. This not only reduces operational costs but also supports sustainability initiatives within manufacturing plants. By optimizing mixing processes, companies can significantly reduce waste and enhance productivity, aligning with the increasing focus on resource efficiency in modern industrial operations.

: Key maintenance tips include conducting regular inspections, timely servicing, routine cleaning, and lubrication of mixing blades and bearings.

Routine lubrication reduces friction and prevents wear and tear, potentially extending the mixer’s operational life by up to 25%.

Proper calibration avoids unnecessary strain on the motor, preventing overheating and premature failure of the mixer.

Paddle mixers are widely used in the food, chemical, and pharmaceutical industries.

Paddle mixers can effectively blend semi-solid and pasty substances, including powders, granulates, slurries, polymers, and resins.

Their design allows for both gentle and thorough mixing, which is crucial for achieving consistent product quality in food applications.

The global paddle mixer market is projected to grow at a CAGR of 5.6% from 2021 to 2026.

Paddle mixers ensure optimal homogeneity when mixing active ingredients with excipients, which is essential for manufacturing tablets and other dosage forms.

Paddle mixers demonstrate significant adaptability and are beneficial for materials that need specific shear forces or where bulk density is a concern.

Regular inspections lead to early detection of irregularities, promoting proactive management and ensuring sustained productivity in the mixing process.

A Paddle Mixer is an essential tool for various industrial mixing needs due to its unique design and efficiency. Understanding how Paddle Mixers operate highlights their advantages, such as uniform mixing and the ability to process a wide range of materials. Many key industries, including food, pharmaceuticals, and construction, leverage Paddle Mixing technology for its effectiveness.

When comparing Paddle Mixers to other types of industrial mixers, their specialized functionality often makes them the preferred choice for numerous applications. Selecting the right Paddle Mixer is crucial for optimizing performance, and proper maintenance can significantly enhance its longevity. With diverse applications and materials processed, Paddle Mixers remain a vital component in modern industrial operations.