Hey, if you're into industrial mixing, you’ve probably come across the Ribbon Mixer. It’s pretty much a rockstar when it comes to getting things done efficiently and with versatility. I was reading this report from Grand View Research, and it says that the Global Mixer market is actually growing at around 4.6% per year from 2020 to 2027. That’s pretty significant and really shows how much demand there is for high-quality mixing solutions across different industries. Companies like Schenck Process and Schutte-Buffalo are already noticing it too—they’re seeing more sales, mainly because their Ribbon Mixers are doing a great job of creating uniform blends consistently.

So, how does a Ribbon Mixer work? Well, it basically has this helical ribbon that spins around a central shaft. The design is pretty clever because it allows for continuous, thorough mixing while stuff keeps moving through. That said, while many manufacturers rave about how well it works, you should keep in mind that sometimes, depending on what you’re mixing, the results might not be perfectly even—especially if the materials vary in density or moisture content. It’s worth thinking about these things beforehand to avoid surprises.

As industries keep evolving, it’s a good idea to revisit those old-school methods and see what still makes sense. The Ribbon Mixer strikes a pretty nice balance between simplicity and complexity, fitting well with modern manufacturing needs. Still, before jumping in and buying one, it’s crucial to look at your specific requirements. If you get what the Ribbon Mixer can do—and recognize its possible limitations—you’ll be in a better position to make smarter choices that can really boost your production game.

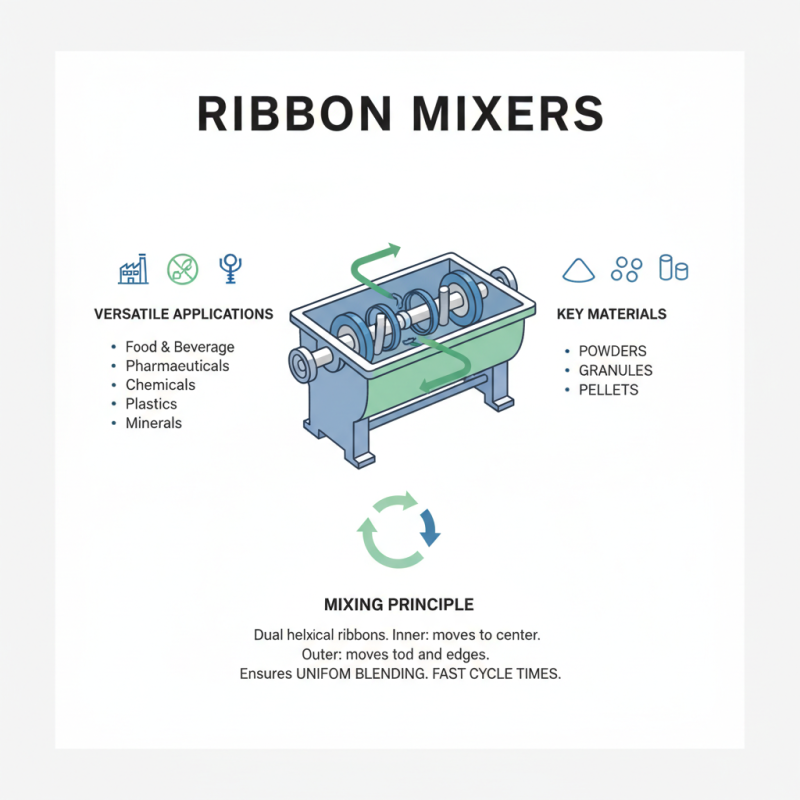

A ribbon mixer is a vital piece of equipment in various industries. It is primarily designed for blending dry powders, granules, and pellets. The design features a set of helical blades, which resemble ribbons, that effectively move materials in a horizontal cylindrical trough. This unique configuration ensures a consistent and homogeneous mixture. According to recent industry reports, the global ribbon mixer market is forecasted to grow by over 5% annually. This growth highlights its importance in sectors like food processing, pharmaceuticals, and chemicals.

The primary applications of a ribbon mixer are extensive. In the food industry, it is used for mixing flour, sugar, and spices. These ingredients must be evenly distributed to maintain quality. In pharmaceuticals, precise mixing is crucial for active ingredients in tablets. Studies indicate that improper blending can lead to significant variations in dosage, which could have serious implications. Ribbon mixers help mitigate this risk by providing uniform mixing with minimal disruption to the materials.

Despite its advantages, not every mixing process benefits from this equipment. Some materials may require gentler handling. This could lead to degradation if blended too aggressively in a Mixer Ribbon. Additionally, certain humid materials can clump, making it difficult for the mixer to achieve a homogenous blend. Users must recognize these limitations when considering their mixing needs. This reflection can help optimize operations and improve overall efficiency.

A Ribbon Mixer is essential for blending bulk materials efficiently. Understanding its components provides insights into its design and functionality. At the core of a Ribbon Mixer lies its helical ribbon. This component rotates around a shaft, creating a unique motion that transports materials inward and outward. The design allows for consistent mixing, making it suitable for various industries.

The outer shell is another crucial element. It aids in stability and durability while allowing easy access for cleaning. Studies indicate that ribbon mixers can achieve a mixing efficiency of over 90%. This figure highlights their importance in achieving uniformity in mixtures. Additionally, the shape and length of the ribbon can significantly affect the mixing process.

Another layer of complexity exists in the inlet and outlet designs. If not properly aligned, these components can create material build-up. Users often overlook this detail, which can hinder performance. To minimize such issues, operators need to ensure proper maintenance and regular assessments. The overall efficiency of a Ribbon Feed Mixer can diminish if any component is neglected. Therefore, ongoing evaluations are essential for maintaining optimal function.

A ribbon mixer is an essential tool in various industries. It combines solid materials efficiently. Understanding the mixing process requires a closer look at its components. A ribbon mixer consists of a U-shaped trough and two helical ribbons. These ribbons rotate around a central shaft. They move ingredients in both directions. This action ensures thorough blending.

During the mixing process, materials are fed into the trough. The rotation of the ribbons creates a continuous flow. This flow causes particles to rise and fall repeatedly, enhancing homogeneity. Reports indicate that achieving a uniform mixture can increase product quality by 30%. However, inconsistency in feed rates or ingredient sizes can lead to subpar results. That's a challenge many face.

Temperature and moisture can also affect the mixing outcome. Certain ingredients may clump together if not handled correctly. Overmixing can lead to degradation of sensitive materials. Manufacturers must be vigilant to avoid these pitfalls. Operational efficiency is crucial for profitability in food processing, pharmaceuticals, and chemicals. Yet, many facilities still underestimate the importance of regular maintenance. This can hinder performance and increase downtime, affecting overall productivity.

In various industries, ribbon mixers provide significant advantages. Their design allows for efficient blending of powders, granules, or pastes. This machine uses two helical ribbons to move materials in opposite directions. This action ensures uniform mixing, crucial in food, pharmaceuticals, and construction.

Tip: Choose the right size ribbon mixer for your operation. Too small might underperform, while too large could waste resources.

The versatility of ribbon mixers is impressive. They can handle various materials, from light powders to heavy granules. This adaptability makes them a favorite in sectors like agriculture and plastics. Additionally, they are relatively easy to clean. This feature saves time, especially in production cycles.

Tip: Regular maintenance is key to longevity. Check for wear and tear on ribbons. Small issues can escalate quickly.

Despite their benefits, ribbon mixers have some limitations. They may not achieve perfect homogeneity in some cases. Users should assess their mixing needs carefully. Sometimes, additional equipment might be necessary to meet specific requirements.

Tip: Experiment with different mixing times. Find the balance that suits your material best.

Ribbon mixers are versatile machines used in various industries. They mainly handle dry materials, including powders, granules, and pellets. The mixing process in a ribbon mixer occurs through the rotation of helical ribbons, which propel materials toward the center and then back to the edges. This unique configuration ensures thorough mixing in a relatively short period.

Several materials are commonly processed by ribbon mixers. According to industry reports, dry powders like flour and sugar are frequently mixed. These mixers are also efficient for materials like chemicals, pigments, and fertilizers. The pharmaceutical sector relies on ribbon mixers for uniform blending of active ingredients in tablets. Many users appreciate the speed of mixing, but the challenge lies in achieving uniformity for all materials, especially when dealing with materials of varying densities.

In food processing, ribbon mixers ensure consistent distribution of ingredients, maintaining flavor and texture. However, achieving homogeneity with products that have sticky or cohesive properties can be problematic. In construction, cement and sand often require blending. Yet, moisture control remains an issue. While ribbon mixers are practical, their limitations must be acknowledged. Each application has distinct requirements that can hinder optimal performance at times.

Proper maintenance is crucial for the optimal performance of Ribbon Type Mixer. Regular inspections can prevent small issues from escalating. Check the ribbon blades and ensure they are not worn out. If they are, replacing them can enhance mixing efficiency. Cleaning the mixer after every use helps in avoiding residue build-up. This can lead to operational problems and contamination of future batches.

Routine lubrication of moving parts is essential. Lack of grease can cause friction, leading to mechanical failures. Operators should keep an eye on the motor and gearbox as well. Any unusual noises could indicate potential concerns. Addressing these sounds early can save time and costs later on.

Lastly, ensure that the mixer is level when in operation. An unbalanced machine can lead to uneven mixing and premature wear on components. Operators should also reflect on their mixing processes. Consider if the current technique meets production standards effectively. Regularly revisiting these practices can lead to better outcomes.

When it comes to industrial mixing, ribbon mixersstand out for their versatility and efficiency. They excel in blending dry materials, achieving uniformity in short cycles. This performance often leaves other Mixing Equipment—like paddle or drum mixers—struggling with consistency. According to a recent industry report,ribbon mixers can complete a mixing task in just 3 to 5 minutes, while paddle mixers may take double that time for similar volumes.

The Small Ribbon Mixer is especially effective for small to medium batch sizes. Its compact design allows for easy integration into existing lines. However, not all mixing processes are suited for ribbon mixers. Some applications, particularly those requiring very gentle mixing, might see better results with fluidized bed mixers. The speed and intensity of a ribbon mixer can sometimes lead to particle degradation or segregation, issues not commonly faced by those alternative mixers.

Data suggests that nearly 30% of companies are still unaware of the full potential of ribbon mixers. This gap in understanding can result in suboptimal mixing solutions. The variability in material types and properties also challenges the notion that one size fits all. With careful analysis and choice of equipment, operations can maximize efficiency and minimize waste. Understanding these dynamics is key to improving overall production quality.

The pull-type gravity-free mixer represents a significant advancement in material processing efficiency, particularly in the food industry. Designed specifically for applications such as food seasonings and prepared vegetable seasonings, this innovative equipment ensures extremely high hygiene levels, addressing the stringent cleanliness requirements of the industry. Its sophisticated design allows for comprehensive cleaning over extended periods, making it an ideal choice for establishments that prioritize sanitation and efficiency.

Utilizing cutting-edge technology, the pull-type gravity-free mixer simplifies the blending process, making it an invaluable tool for both professional chefs and home cooks alike. The unique pull-type mechanism enhances mixing capabilities, ensuring that ingredients are blended thoroughly and uniformly, which is essential for high-quality culinary creations. This not only improves the overall taste and consistency of dishes but also streamlines kitchen operations, allowing for faster preparation times.

In addition to its efficient blending capabilities, the mixer is built with the user in mind, offering convenience that enhances the cooking experience. By integrating this advanced equipment into food processing workflows, businesses can achieve higher productivity while maintaining exceptional quality standards, thus positioning themselves for success in a competitive market.

: The articles explore personal growth and self-improvement. They emphasize the importance of resilience.

Yes, they suggest setting clear goals and being mindful of daily habits. Small changes can lead to big results.

Facing challenges requires a positive mindset. Reflecting on past experiences helps to build strength.

Definitely. Tracking progress provides motivation. It can also highlight areas needing adjustment.

Reflection allows for deeper understanding. It helps identify successes and areas needing improvement.

Consistency is key. Celebrating small wins keeps the momentum going. Also, seeking support can boost motivation.

Yes! Setbacks can teach valuable lessons. Embracing them can lead to greater resilience.

No, the journey matters too. Enjoying the process can enhance satisfaction. It's not just about the destination.

Absolutely. Many people face uncertainty. Acknowledging these feelings can be the first step toward clarity.

A Ribbon Mixer is a versatile piece of equipment widely used in various industries for mixing powders, granules, and other bulk materials. It consists of a helical ribbon auger that rotates within a U-shaped trough, facilitating efficient mixing by creating a flow pattern that moves materials towards the center and back out to the edges. The design and components of a Ribbon Mixer allow for a uniform blend, making it ideal for applications ranging from food processing to chemical manufacturing.

The operation of a Ribbon Mixer is characterized by its ability to combine materials thoroughly while maintaining their integrity, which is critical for achieving consistent product quality. The benefits of using a Ribbon Mixer include reduced mixing times, improved product homogeneity, and versatility in handling various materials. To ensure optimal performance, regular maintenance is essential, and users can benefit from understanding how Ribbon Mixers compare to other mixing equipment in terms of efficiency and effectiveness.