Today’s textile game is all about efficiency, right? That’s where a Fiber Mixing Machine can really help speed things up. But honestly, just having one isn’t enough—you gotta know how to use it properly. It’s worth taking the time to learn the ins and outs, because with a bit of practice, you’ll be mixing like a pro. In this article, I’ll share some of my top tips to make sure you get the most out of your machine.

First off, understanding your Fiber Mixing Machine is super important. Every model has its own quirks and features. Spend a little time getting familiar with the controls—trust me, this can save you from some pretty awkward mishaps later on. And don’t forget about maintenance; keeping the machine in good shape is key. Ignoring it can lead to breakdowns that are a real pain and expensive to fix.

When it comes to the fibers you’re mixing, pay attention to what works well together. Some materials blend smoothly, while others might not be so cooperative. Don’t be afraid to experiment with different combinations—you might stumble upon some great results. Just keep in mind, not every tweak will turn out perfect on the first try, and that’s totally okay. Those challenges are just part of the learning process. In the end, taking a thoughtful, patient approach can really make a difference in your mixing results.

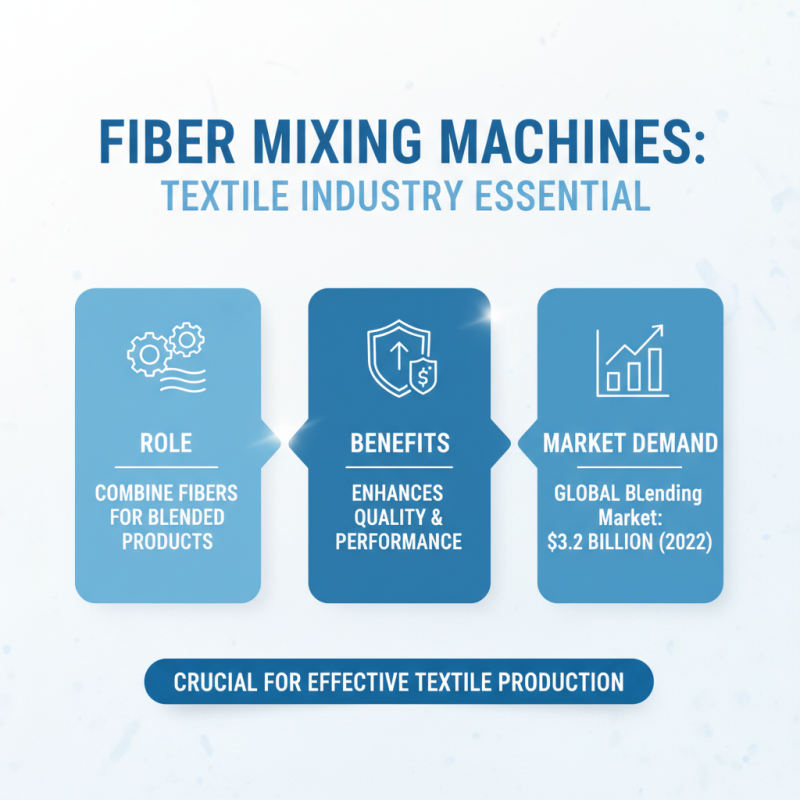

Fiber mixing machines play a pivotal role in the textile industry. Understanding their basics is crucial for effective use. These machines combine different fiber types to create blended products, enhancing quality and performance. The global fiber blending market reached USD 3.2 billion in 2022, indicating a growing demand.

Proper operation begins with understanding fiber properties. Different fibers have unique characteristics. For instance, natural fibers like cotton absorb moisture differently than synthetic fibers like polyester. Mixing them without knowledge can lead to poor fabric quality. Data shows that 25% of textile defects stem from inadequate blending techniques.

Regular maintenance is also key. Neglecting machine upkeep can result in inconsistent blends. Research reveals that 30% of operational downtimes are due to maintenance oversights. Operators must ensure that settings align with specific fiber types. Complicated blends often require adjustments during the mixing process. Reflecting on these aspects can significantly enhance the mixing outcome.

When using a fiber mixing machine, selecting the right fiber materials is crucial. Different fibers have unique properties. For example, natural fibers like cotton and wool behave differently than synthetic options. Mixing materials with varying lengths and textures can lead to unexpected results. You might end up with uneven blends. This can affect the final product quality.

Consider the moisture content of your fibers. Natural fibers often retain moisture, while synthetic ones do not. This can cause clumping when mixed together. Testing small batches first can help identify these issues. It’s a step often overlooked, yet it’s essential for effective mixing. Additionally, mixing fibers with contrasting colors can enhance the visual appeal of the final product, but achieving a uniform appearance can be challenging.

Understanding the compatibility of materials is also important. Some fibers might not bond well, creating weak spots in the mix. This can lead to problems down the line. It’s worth examining how different fibers interact. Taking these factors into account is necessary for mastering the art of fiber mixing. You may find yourself reflecting on the balance between creativity and technical precision.

Setting up your fiber mixing machine properly is crucial for achieving optimal performance. The placement of the machine matters. Ensure it’s on a stable, level surface to reduce vibrations. A report by Industry Weekly indicates that improper setup can lead to a 15% decline in efficiency. Positioning can also affect the fiber flow. If fibers are mixed unevenly, the end product quality deteriorates.

Maintenance is another key aspect. Regularly check the machine for wear and tear. A survey shows that 25% of operators neglect routine checks. This oversight can cause mixing inconsistencies over time. Use high-quality fibers to begin with. Cheap materials can lead to poor mixing and longer processing times. Instant feedback from operators can help identify areas for improvement in real-time. Sometimes, input from your team can reveal setup flaws that are easy to overlook.

The mixing speed and duration should also be calibrated accurately. Too fast and fibers may break or not blend well. Too slow, and mixing takes too long. It's essential to document your adjustments and results. This data can help refine your process. Review it regularly. Even the best machines require fine-tuning. Test your fiber mixes often. User feedback is invaluable for improvement. Don't assume perfection; strive for constant enhancement.

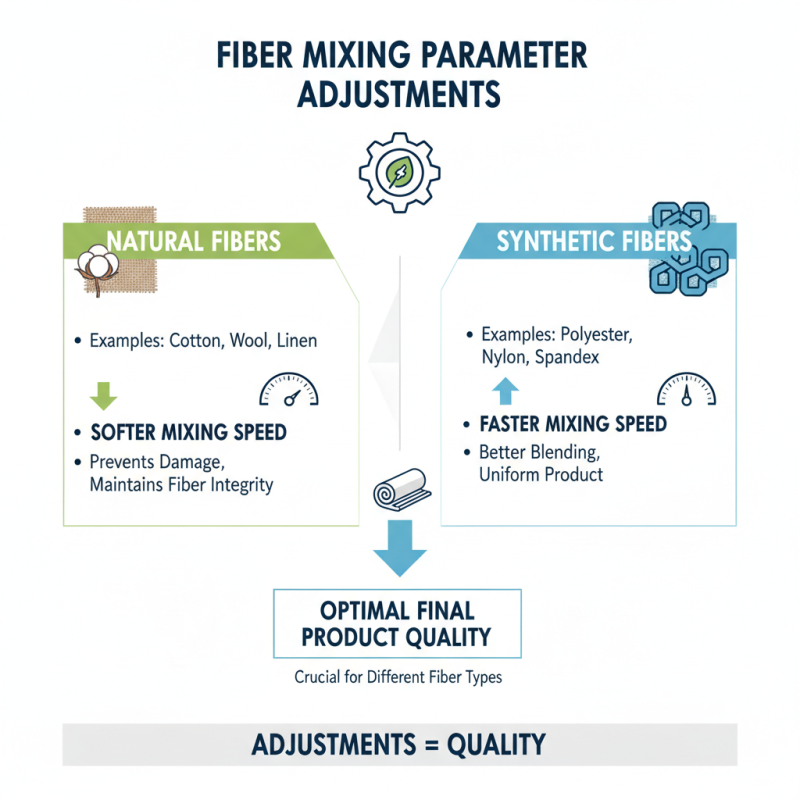

When working with a fiber mixing machine, adjusting mixing parameters is crucial for different fiber types. The fiber composition can significantly impact the final product's quality. Each fiber type requires distinct settings to achieve optimal results. For instance, natural fibers often need softer mixing speeds to prevent damage, while synthetic fibers may require faster speeds for better blending.

Research from the Textile World shows that improper adjustments can lead to a 30% decrease in mixing efficiency. This decline can result in uneven distribution of fibers, ultimately affecting fabric strength and texture. It’s vital to monitor the temperature and humidity levels during the mixing process. High humidity can cause fibers to clump, leading to non-uniform mixtures. Operators should regularly check these environmental factors and adapt machine settings accordingly.

Moreover, operators must be aware of fiber length and density. Longer fibers may tangle more easily, necessitating slower mixing speeds. For example, using a machine setting intended for short fibers can produce unexpected results and potential fiber breakage. A balance must be struck between speed and care to optimize the mixing process. Regularly reviewing and refining these parameters can lead to improved outcomes.

Proper maintenance of your fiber mixing machine is essential for its longevity. Regular cleaning is a must. Dust and debris can accumulate, affecting performance. Schedule consistent cleanings. After each shift, wipe down all surfaces. Use compressed air to blow out hard-to-reach areas. This simple step prevents buildup and extends the machine’s life.

Lubrication is another key factor. Check the machine’s moving parts regularly. Apply lubricant as needed to avoid friction. Neglecting this can lead to breakdowns. Keep an eye on wear and tear as well. Any unusual sounds can indicate a problem. Don't ignore them; they may be signs needing immediate attention.

Lastly, ensure proper training for operators. A well-informed team can prevent mistakes that lead to damage. Encourage them to report issues promptly. Regularly review operational procedures to keep everyone updated. These small actions can create a big impact on your fiber mixing machine’s efficiency and longevity.

Troubleshooting is crucial when using a fiber mixing machine. Common issues often arise during operation. For instance, uneven fiber distribution can lead to subpar products. This issue may stem from improper loading of fibers. Ensuring even distribution before mixing can alleviate this.

Another common problem is machine jams. Clogged fibers can cause delays and frustration. Regularly check the feed mechanism for blockages. Sometimes, finer fibers can get stuck and create these problems. Adjusting the feed rate might also help to prevent jams.

Finally, monitor the machine's performance closely. If unexpected noises occur, this could indicate internal wear. Addressing these sounds early can prevent larger issues. Regular maintenance is essential for smooth operation. Keeping a log of issues can assist in identifying patterns and finding solutions.

Operating fiber mixing machines can pose significant safety risks if proper precautions are not followed. According to industry reports, around 32% of workplace accidents in textile manufacturing involve machinery injuries. It’s crucial to prioritize safety protocols when using these machines.

Always wear protective gear. This means gloves, safety goggles, and ear protection. Loose clothing can get caught in moving parts. A report from the Textile Machinery Association states that entanglement accounts for 18% of injuries. Machines should have proper safety guards to prevent operator injury. Regular maintenance checks can help identify issues before they lead to accidents.

Training is vital for all operators. Many accidents are due to a lack of understanding about machine functions. A survey found that 47% of new operators did not receive adequate training. Supervisors must ensure personnel are well-informed. Conducting safety drills can also reinforce good practices. Keeping a clean workspace reduces hazards. Spills or clutter increase the risk of slips and falls, which can be overlooked in busy environments.

The HEP-SYLW series drying and Blending Machine represents a significant advancement in manufacturing efficiency, particularly within the framework of Industry 4.0. Designed to address common issues such as moisture retention and clumping in finished products, this innovative solution integrates advanced far-infrared ceramic heating technology. This feature ensures a thorough drying process, allowing moisture-returning materials to be effectively processed during the final mixing stage. This capability not only enhances the quality of the final product but also streamlines operations, making it a crucial asset for manufacturers aiming to optimize their production workflows.

In an industry where operational capacity can often limit productivity, the HEP-SYLW series stands out by offering a batch processing capacity that exceeds the market standard. While many blending machines typically handle 10-15 tons per batch, this model can efficiently manage up to 40 tons in a single cycle. This increased capacity not only allows for higher volume production but also fosters a more consistent and reliable mixing process. As manufacturers seek solutions that deliver both efficiency and quality, the HEP-SYLW series aligns perfectly with the evolving demands of modern industry, showcasing the potential for enhanced operational performance in the era of smart manufacturing.

: Regular exercise improves physical health, boosts mood, and increases energy levels. It's crucial for overall well-being.

Begin with simple activities. Aim for short sessions, gradually increasing duration and intensity. Consistency is vital.

Many people overestimate their abilities and push too hard. This can lead to injury and burnout.

Nutrition plays a key role. Balanced meals provide energy. Proper hydration is also essential for performance.

Yes, exercise is known to reduce anxiety and depression. It promotes the release of feel-good hormones.

Most adults should aim for at least 150 minutes of moderate exercise each week. Breaking it down is helpful.

No, many effective workouts require no gym. Home exercises, running, or outdoor activities can be great alternatives.

Rest is often overlooked. It allows muscles to recover and grow, preventing fatigue and overtraining.

Set realistic goals and track progress. Find a workout buddy or try new activities for fun and motivation.

Results take time and vary for everyone. Consistency and patience are key. Reflect on your routine if needed.

The article "Top 10 Tips for Using a Fiber Mixing Machine Effectively" provides essential guidance for optimizing the use of fiber mixing machines. It begins by explaining the fundamental principles behind these machines, emphasizing the importance of selecting appropriate fiber materials to ensure efficient mixing. Proper setup of the fiber mixing machine is crucial for achieving optimal performance, as is adjusting mixing parameters depending on the fiber types being used.

Regular maintenance is highlighted as a key factor in extending the longevity of a fiber mixing machine, along with effective troubleshooting techniques to address common issues that may arise during operation. Finally, the article underscores best practices for safety, ensuring that operators remain protected while using these machines. By following these tips, users can maximize the efficiency and effectiveness of their fiber mixing processes.