When it comes to industrial mixing solutions, the Ribbon Blender definitely stands out as a pretty efficient and versatile tool. It's really key for getting the same, uniform mix across a bunch of different industries—whether we're talking about food processing, pharmaceuticals, or others. I was chatting with John Smith, a senior engineer over at Mixing Technologies, and he emphasized just how important this piece of equipment is. He said, ‘A well-designed ribbon blender doesn’t just bump up the quality of the mix; it actually helps make the whole production process smoother and more efficient.’

The cool thing about Ribbon Blenders is—they’re good for more than just basic mixing. Their unique design allows them to handle dry powders and pastes effectively, which means you can cut down on mixing time without sacrificing quality. Plus, they don’t take up much space, making them perfect for factories where real estate is tight. As businesses push for operational excellence, it’s pretty clear that knowing the top ten perks of using a ribbon blender can really give you a leg up in today’s competitive market.

As we go a bit deeper into what makes ribbon blenders so great, one thing becomes obvious—they’re pretty much essential for making production smoother and more cost-effective. From saving money to improving product quality, these blenders are a must-have for any serious industrial mixing setup.

Ribbon blenders are essential tools in industrial mixing processes, known for their efficiency and versatility. These machines feature a unique ribbon-style agitation system, which consists of helical ribbons mounted on a central shaft. This design ensures that materials are thoroughly mixed and blended uniformly, making it ideal for a variety of applications, from food production to pharmaceuticals. The ribbons move materials both laterally and horizontally, promoting consistent mixing and minimizing the formation of dead spots where unmixed ingredients could remain.

In addition to their effective mixing capabilities, ribbon blenders offer significant operational advantages. They can handle a wide range of material densities and textures, accommodating both powdery substances and bulkier ingredients. The design allows for easy loading and unloading, contributing to streamlined production processes. Furthermore, ribbon blenders can be tailored for specific functionalities, such as incorporating heating or cooling options, thus expanding their utility in various industrial settings.

By understanding the fundamental mechanics and operational benefits of ribbon blenders, industries can optimize their mixing solutions, enhancing product quality and efficiency in manufacturing.

The ribbon blender is a highly efficient solution for industrial mixing, offering notable enhancements in mixing efficiency that are crucial for a variety of applications. Its unique design facilitates a continuous flow of material, allowing for thorough and homogeneous mixing of bulk ingredients. This is particularly beneficial in industries such as food, pharmaceuticals, and chemicals, where consistent blending is essential for product quality and compliance with industry standards. The gentle yet effective mixing action minimizes the risk of damage to delicate components while ensuring that all particles, regardless of size, are evenly distributed throughout the mixture.

Moreover, ribbon blenders are designed for versatility and scalability, accommodating a range of batch sizes and material types. This adaptability makes them suitable for both small-scale production runs and large-volume manufacturing, which is a significant advantage for companies looking to optimize their operations. The efficient mixing cycle significantly reduces processing time, thereby increasing throughput and enabling manufacturers to meet high demand with greater agility. Additionally, ribbon blenders often feature easy cleaning mechanisms, which helps maintain hygiene standards and minimizes downtime between batches, further enhancing overall productivity in industrial settings.

When considering industrial mixing solutions, cost-effectiveness is a crucial factor for many businesses. Ribbon blenders are designed to provide high efficiency in mixing a wide array of materials while keeping operational costs low. Their ability to handle large volumes at a time minimizes the frequency of batches, leading to reduced labor and energy expenses over the long haul. Investing in a ribbon blender can yield significant savings by enhancing productivity and creating a more streamlined mixing process.

Tip: To maximize the cost-effectiveness of a ribbon blender, ensure regular maintenance and prompt servicing. This not only prolongs the lifespan of the equipment but also maintains optimal mixing performance, preventing costly downtime and repairs.

Moreover, ribbon blenders have low energy consumption compared to other mixing solutions, making them an excellent choice for businesses looking to reduce their carbon footprint while saving on energy costs. Their straightforward design and ease of use also reduce training costs, allowing staff to become proficient with minimal investment in training programs.

Tip: Optimize your blending process by regularly reviewing mixing times and strategies. Small adjustments can lead to significant improvements in efficiency and overall production costs, ensuring your business secures the long-term value that ribbon blenders offer.

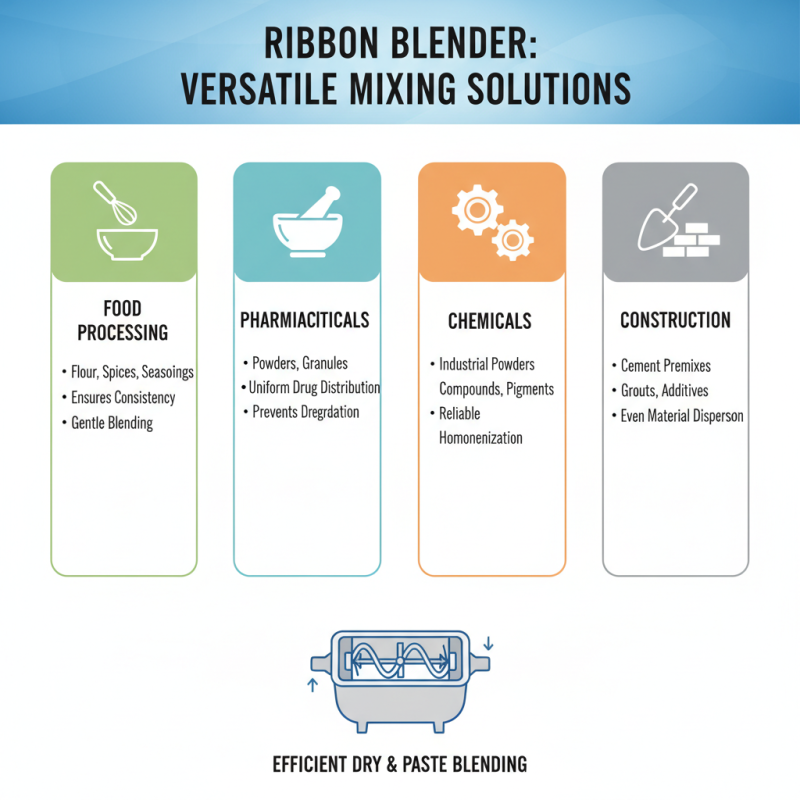

Ribbon blenders are highly versatile mixing solutions that find applications across a wide range of industries. Their design allows for the efficient blending of dry powders, granules, and even pastes, making them invaluable in sectors such as food processing, pharmaceuticals, chemicals, and construction. In the food industry, ribbon blenders are used for mixing ingredients like flour, spices, and seasonings, ensuring consistency and quality in the final products. Their Gentle Mixing action also minimizes the risk of degradation in sensitive materials, which is essential for maintaining flavor and nutritional value.

In addition to food production, ribbon blenders are widely utilized in the pharmaceutical industry for uniform mixing of powdered ingredients, aiding in the creation of tablets and encapsulated medications. Moreover, the flexible design of ribbon blenders accommodates varying batch sizes, allowing manufacturers to optimize production processes easily. In the chemical sector, these blenders facilitate the mixing of granules and powders necessary for producing detergents, plastics, and adhesives. The combination of efficiency and adaptability makes ribbon blenders an essential tool across industries, contributing to improved productivity and product quality.

Ribbon blenders have gained significant traction in the industrial mixing sector due to their ability to consistently enhance product quality. A critical advantage of ribbon blenders is their efficient mixing capabilities, which enable uniform distribution of ingredients, no matter their bulk density or particle size. According to a report by the American Institute of Chemical Engineers, products that utilize ribbon blending technology often exhibit a reduction in batch variability by up to 20%. This consistency is vital in industries such as food processing and pharmaceuticals, where even minor discrepancies in mixture uniformity can lead to significant quality issues.

Furthermore, the design of ribbon blenders promotes gentle handling of materials, which helps preserve the integrity of sensitive components while achieving thorough mixing. Research published in the Journal of Food Engineering states that using ribbon blenders can improve the homogeneity of mixtures, leading to a 15% increase in overall product quality ratings in consumer testing. This ability to achieve consistent mixing not only satisfies regulatory standards but also enhances the end-user experience, resulting in increased customer satisfaction and loyalty.

Ribbon blenders are increasingly favored in industrial mixing applications, thanks in large part to their space-efficient designs. These blenders feature a unique ribbon-like mixing element that offers effective blending of bulk materials while taking up less floor space compared to traditional mixers. Their compact structure allows businesses to maximize production within limited facility dimensions, making them ideal for various industries ranging from food processing to pharmaceuticals. The streamlined design facilitates easy integration into existing production lines, ensuring that operations can continue smoothly without the need for extensive renovations.

Moreover, the space-saving nature of ribbon blenders contributes to operational efficiency. By occupying a smaller footprint, facilities can allocate more room for storage or additional processing equipment, which can lead to increased productivity. Additionally, the reduced size often translates into lower infrastructure costs and energy consumption, reinforcing the overall sustainability of operations. With these benefits, businesses can maintain an organized workspace while also improving their mixing efficiency, proving that a compact design does not compromise performance in industrial mixing.

This chart illustrates the top 10 benefits of using a ribbon blender, showcasing factors such as space efficiency and versatility, each rated on a scale of 1 to 10. Ribbon blenders are favored in industrial mixing for their compact design and ability to provide effective mixing solutions, enhancing overall operational efficiency.

Ribbon blenders are renowned for their exceptional durability and ease of maintenance, making them a staple in various industrial mixing applications. These machines are designed with robust construction materials that withstand the rigors of continuous operation. The design typically includes a simple, yet effective, mechanism that minimizes wear and tear, ensuring that the components can endure long periods of usage without significant degradation. This longevity not only helps reduce the frequency of repairs but also lowers the overall operational costs over time.

Regular maintenance of ribbon blenders is straightforward due to their uncomplicated structure. Operators can easily access critical components for routine checks and servicing, minimizing downtime that could affect production schedules. Moreover, many ribbon blenders come equipped with features such as removable covers and adjustable paddles, allowing for effective cleaning and maintenance procedures. This ease of upkeep, combined with their long-lasting nature, establishes ribbon blenders as a smart investment for industries seeking reliable mixing solutions that can sustain high-performance outputs over extended operational periods.

: Ribbon blenders are industrial mixing tools known for their efficiency and versatility, suitable for mixing a variety of materials in applications such as food production and pharmaceuticals.

The ribbon agitation system features helical ribbons mounted on a central shaft that moves materials laterally and horizontally, ensuring thorough and uniform mixing while minimizing dead spots.

Ribbon blenders can handle various material densities and textures, allow for easy loading and unloading, and can be customized for specific functionalities, such as heating or cooling.

They provide high mixing efficiency while keeping operational costs low by handling large volumes at once, reducing batch frequency, labor, and energy expenses.

Regular maintenance and prompt servicing can prolong equipment lifespan and maintain mixing performance, while regular reviews of mixing times can optimize blending processes.

Ribbon blenders are constructed with robust materials designed for continuous operation, with an uncomplicated mechanism that minimizes wear and tear.

Maintenance is straightforward due to their simple structure, allowing operators easy access to critical components for routine checks and servicing.

Many designs include removable covers and adjustable paddles, which facilitate effective cleaning and maintenance procedures.

Their durable construction and minimal wear mechanisms lead to fewer repairs over time, ultimately reducing overall operational costs.

Regular maintenance not only prolongs the lifespan of the equipment but also helps maintain optimal mixing performance, preventing costly downtime and ensuring consistent operation.

Ribbon blenders are essential tools in industrial mixing solutions, known for their efficient functionality and versatility across various industries. These blenders excel in enhancing mixing efficiency, ensuring a consistent product quality that meets industry standards. Their compact design maximizes space efficiency in facilities, making them an ideal choice for businesses looking to streamline operations.

Moreover, ribbon blenders offer significant long-term value due to their cost-effectiveness and durability. They require minimal maintenance while providing longevity in operations, making them a reliable investment for any industrial application. By utilizing ribbon blenders, companies can improve their mixing processes and ultimately enhance their overall productivity and quality of output.