Choosing the right Powder Mixer can honestly feel a bit overwhelming at first. There are so many options out there from companies like Schenck Process and J.R. Boone Manufacturing, each with their own set of features. It’s kind of like shopping for a new gadget—you want to pick something that’s actually going to boost your workflow, not just look good on paper.

Getting the perfect Powder Mixer isn’t just about picking the fanciest model. You’ve gotta think about stuff like mixing speed, capacity, and how tough it is—stuff that really impacts how well it fits into your production. Sometimes, a model might seem perfect but ends up not meeting your specific needs, which can slow things down and cause frustrations.

So, investing in a solid, reliable Powder Mixer really pays off down the line. Not all brands are created equal though—some keep quality high, others less so. It's worth taking some time to check out reviews and really dive into the specs before making your decision. That way, you’re more likely to pick something that sticks with you and makes a difference in your operation, instead of just another piece of equipment collecting dust.

CE certification plays a crucial role in the manufacturing of powder mixers. It ensures that a product meets stringent safety and quality standards. This certification is essential for companies looking to sell their mixers in the European market. Understanding it can help you make informed decisions.

When considering a Lab Powder Mixer, check for CE certification. This certification confirms the product’s conformity to European safety directives. Look for details about testing processes and compliance measures. Not all manufacturers provide clear information. It's wise to ask questions and demand transparency.

Tips: Always consider user reviews before purchasing. They can reveal the real performance of a Lab Powder Mixer. Ensure the factory can provide reliable after-sales support. Understand the warranty conditions. Choose wisely; not all options meet high standards.

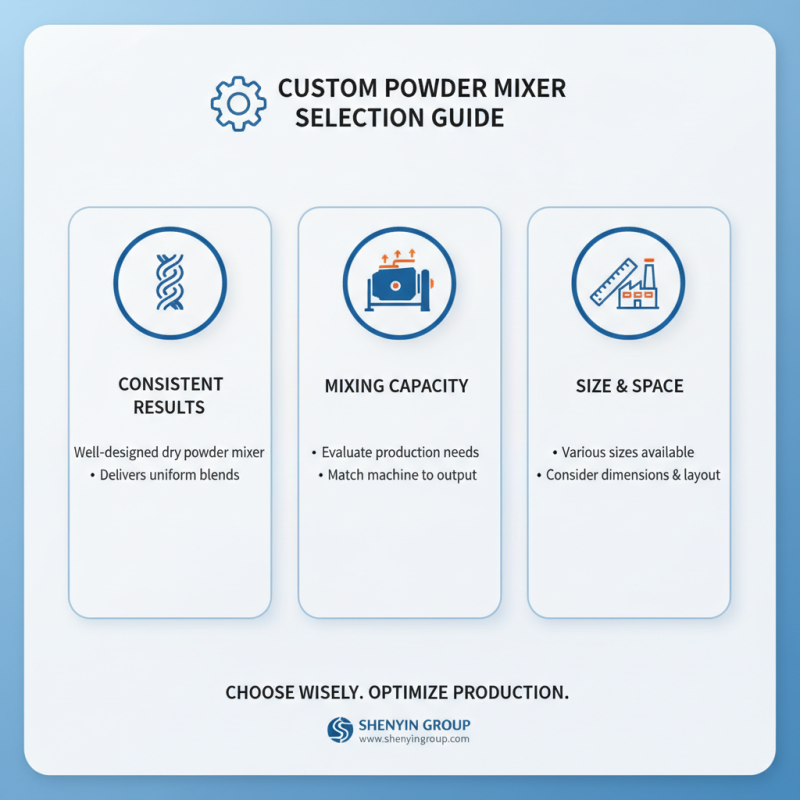

When selecting a Custom Powder Mixer, key features should be examined carefully. A well-designedDry Powder Mixer should deliver consistent results. It is essential to evaluate the mixing capacity. Choose a machine that meets your production needs effectively. Many mixers come in various sizes and capabilities, so consider the dimensions that work best for your space.

Another crucial aspect is material compatibility. Ensure that the mixer can handle different powder types without contamination. Some mixers struggle with sticky or coarse powders, which can lead to inefficiencies. Look for models that demonstrate versatility in handling various materials. Additionally, ease of cleaning is vital. Clean equipment reduces downtime and improves hygiene standards.

Finally, think about control features. Modern mixers often offer programmable settings. This allows for precise adjustments to mixing speed and time. Mechanical failures can occur, so having a monitoring system is beneficial. Consider the user interface too; it should be intuitive and straightforward. Even with top-notch equipment, familiarizing yourself with controls can take time. A thoughtful decision on these attributes will enhance productivity and mitigate future challenges.

When searching for powder mixers, considering CE certification is crucial. CE certification ensures that products meet European safety standards. This is important for manufacturers looking to guarantee quality and safety in their operations.

Many manufacturers offer a range of powder mixers. Each factory provides different options. Customization is often available to suit various needs. Look for features that matter to you, such as capacity and mixing efficiency. Pay attention to the materials used. Durable components can enhance the longevity of your equipment.

**Tips**: Always check for customer reviews. Feedback can reveal the strengths and weaknesses of a mixer. Don’t overlook after-sales support; it can make a difference over time.

Investing in a CE certified mixer is wise for any operation. Ensure that the factory you choose has a solid reputation. A bit of research can help you avoid pitfalls. Sometimes, the cheapest option may not be the best. Quality should always come first.

When considering a custom powder mixer factory, evaluating various options is crucial. A Food Powder Mixer can enhance efficiency in blending ingredients. Different factories may offer varied designs and features. Take time to analyze each option's specifications. Some may lack versatility. Others may excel in production speed but compromise on quality.

Not all factories prioritize after-sales support. Some might provide minimal guidance after installation. This can lead to user difficulties in optimizing their Food Powder Mixer. Quality control processes vary widely. You may find that certain factories cut corners, affecting product consistency. Transparency in manufacturing processes is an important factor to assess.

It’s essential to consider the scalability of your chosen factory. Some mixers work well for small batches but struggle with larger production scales. If not properly evaluated, this might cause headaches down the line. Additionally, don't overlook energy efficiency. A high-energy mixer can inflate operational costs. Balancing performance and expense is key to a successful investment in a powder mixer factory.

When selecting a custom powder mixer factory, quality assurance is key. The effectiveness of a Milk Powder Mixer often hinges on rigorous testing processes. According to industry reports, over 30% of powder mixer failures are due to inadequate testing. Factories must ensure that mixers hold to strict performance metrics to avoid such issues.

Tips: Request detailed testing reports. Look for data on stress testing, mixing efficiency, and maintenance evaluations. These factors can significantly impact the longevity of equipment.

A reliable factory will implement standardized testing protocols. This includes validating the mixer’s ability to maintain consistent powder particle distribution. Studies indicate that inconsistent mixing can lead to product degradation. Therefore, ensure that the factory employs advanced testing methods to confirm optimal performance.

Tips: Ask about pilot runs before bulk orders. This allows you to evaluate the mixer’s performance firsthand. Sampling your product in various mixes can highlight potential issues you may face down the line.

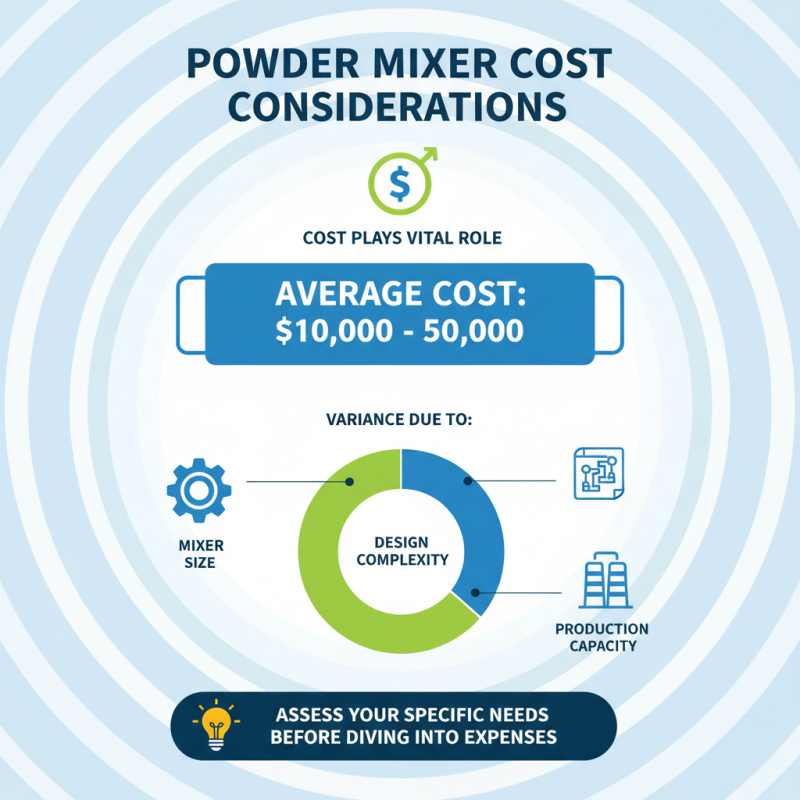

When choosing a powder mixer factory, cost considerations play a vital role. According to a recent industry report, the average cost of custom powder mixers can range from $10,000 to $50,000. This variance is due to several factors such as mixer size, design complexity, and production capacity. Therefore, assess your specific needs before diving into expenses.

Moreover, hidden costs often arise. These can include shipping fees, installation charges, and maintenance costs. A study noted that nearly 30% of businesses overlooked these expenses, impacting their budget. It's crucial to account for these factors. Additionally, purchasing from a factory without a proven track record may result in spending more on repairs or replacements.

Investing in quality often pays off in the long run. A well-made mixer can last between 5 to 10 years. However, inadequate research may lead to choices that fail to meet production requirements. This can cause delays and increased overhead. Understanding your operational demands upfront helps mitigate such risks, ensuring a more informed decision-making process.

When it comes to customizing powder mixers, understanding industry-specific needs is essential. Different industries require unique mixing processes. For instance, food production requires hygiene and compliance standards, while pharmaceuticals demand precise measurements and consistency. Custom solutions often address these specific requirements effectively.

Tips: Consider the materials used in the mixers. Stainless steel is common, but does it meet your needs? Evaluate if other materials may suit your product better.

Moreover, the design of the mixer can greatly impact efficiency. A well-designed mixer ensures uniformity and reduces waste. However, it’s easy to overlook simple features that could improve performance. Regularly reassessing your design and functionality can reveal areas for enhancement.

Tips: Don't forget about maintenance. How often are your mixers serviced? A regular check can prevent larger issues down the line.

Customization doesn’t only mean upgrading tools. Assessing the entire mixing process can lead to significant improvements. Engage with your team and gather insights. Their hands-on experience can highlight overlooked aspects and lead to better-informed decisions.

| Factory Location | Mixing Capacity (kg/h) | Application Industry | Customization Options | CE Certification |

|---|---|---|---|---|

| China | 500 | Pharmaceuticals | Motor Power, Mixing Speed | Yes |

| Germany | 1000 | Food Processing | Material Type, Size | Yes |

| USA | 300 | Cosmetics | Volume, Finish | Yes |

| India | 200 | Chemicals | Heating System, Control Panel | Yes |

| Japan | 800 | Plastics | Automation Features, Dimensions | Yes |

In recent years, the demand for efficient mixing solutions in material processing industries has surged, driven by the need for increased productivity and consistent product quality. High-performance conical screw belt mixers have emerged as a transformative technology, enabling manufacturers to achieve superior mixing in significantly reduced cycle times. According to the latest industry reports, these mixers can improve mixing uniformity by up to 25% compared to traditional methods, which is crucial for industries such as pharmaceuticals, food processing, and chemicals.

Among the innovative designs available in the market, the VJ series conical screw belt mixer stands out with its advanced structural design influenced by top-tier global manufacturers. This mixer combines the functionalities of both screw and belt mixers, ensuring that materials are mixed thoroughly without the risk of segregation. The unique design promotes efficient material flow, reduces energy consumption, and minimizes wear and tear, ultimately leading to lower operational costs. In fact, expert analysis indicates that integrating high-performance mixers can yield operational efficiency improvements of approximately 15-30%, allowing businesses to scale their operations without compromising quality.

Moreover, the versatility of conical screw belt mixers allows them to handle a wide range of materials, including cohesive and fragile substances, without damaging their integrity. As industries increasingly adopt these advanced mixing technologies, manufacturers are poised to benefit from enhanced production capabilities, shorter turnaround times, and the ability to meet stringent regulatory standards. The continuous innovation in mixing technology signifies a pivotal shift towards more efficient manufacturing processes, contributing to the overall advancement of material processing industries.

: Daily exercise boosts mood. It increases energy levels. Regular physical activity enhances overall health. You feel stronger.

Start with small changes. Add fruits and vegetables to meals. Drink more water daily. Limit sugary snacks.

Sleep is essential for recovery. It helps in memory retention. Quality sleep boosts your immune system. It's vital for mental clarity.

Practice mindfulness techniques. Deep breathing can help. Engage in physical activities. Don't hesitate to seek professional help.

Staying hydrated aids digestion. It improves skin health too. Drink water consistently throughout the day. Avoid excessive caffeine.

Yes, you can! Bodyweight exercises work well. Walking or jogging outside is effective. Use online workout videos for guidance.

When selecting a powder mixer, understanding CE certification is crucial for ensuring compliance with safety and quality standards. This article outlines key features of custom powder mixers, emphasizing their importance in various industries. It highlights the top manufacturers that provide CE certified options and offers a comparative analysis of different factory options, assisting in informed decision-making.

Additionally, the article discusses quality assurance and testing processes essential for maintaining efficiency in powder mixing. Cost considerations play a significant role when choosing a factory, as they directly influence the overall investment. Customization of powder mixers to fit specific industry needs ensures that businesses can optimize their operations, making the right choice in powder mixer machinery a priority for long-term success.