You know, the textile world is pretty much on the edge of a major change right now, thanks to new tech and folks wanting more efficient ways to produce. At the heart of all this is the Fiber Mixing Machine—really a game-changer when it comes to blending different fibers. It helps make sure the final fabric comes out just right, with good quality and consistency. I was reading a report from Markets and Markets that said these machines are expected to see a solid growth of about 5.2% annually from 2020 to 2025. That shows more and more industries—like clothing, automotive, and industrial textiles—are jumping on board with these machines.

For manufacturers trying to cut costs and run things more smoothly, investing in a Fiber Mixing Machine just makes sense. Not only does it speed up the blending process, but it also helps cut down on waste and boost overall production. Plus, there's a growing demand for custom fiber blends, which is pushing companies to get even more innovative with these machines. And let’s not forget, sustainability’s become a big deal lately. Modern Fiber Mixing Machines are stepping up by being more eco-friendly, letting companies create top-quality fabrics while also reducing their environmental footprint. If you’re involved in this industry, understanding how these machines fit into the future of textiles is pretty crucial if you wanna stay competitive in such a fast-changing market.

Fiber mixing machines play a crucial role in the textile and materials industry, ensuring efficient blending of various fiber types to create uniform and high-quality products. According to a recent report by the Textile Machinery Association, the global demand for fiber mixing machines is projected to grow by 7% annually through 2025, driven primarily by advancements in manufacturing processes and increasing customization needs in fiber production. These machines not only enhance product quality but also optimize the use of raw materials, reducing waste and improving sustainability in the manufacturing process.

The applications of fiber mixing machines are extensive, spanning across various sectors such as clothing, automotive textiles, and industrial applications. For instance, in the apparel industry, achieving the right mix of fibers is essential for developing fabrics with specific characteristics, such as durability, elasticity, and moisture-wicking properties. A report from the International Textile and Apparel Association highlights that the ability to create blends with unique properties has become increasingly important as consumer preferences shift towards functional and performance-driven textiles. This versatility not only meets the demands of end-users but also supports the industry's shift towards more innovative and sustainable practices.

When selecting fiber mixing machines, understanding key features is essential for maximizing efficiency and product quality. One of the most important aspects to consider is the capacity of the machine. According to a report by Market Research Future, the demand for fiber mixing machines is expected to grow at a CAGR of over 6% from 2021 to 2025, driven by advancements in technology and the need for higher production rates. A machine with an adequate capacity can significantly reduce processing times and enhance productivity for manufacturers.

Another critical feature is the machine's blending technology. Modern fiber mixing machines often incorporate advanced systems that ensure uniform blending of different fiber types, which is crucial for achieving consistent product quality. Features such as adjustable mixing speeds and automated controls can also contribute to better control over the mixing process. A study by Research and Markets indicates that innovations in control automation are expected to boost operational efficiency, reducing labor costs by up to 20%. It's essential for manufacturers to evaluate how these technologies can be integrated into their existing processes for a seamless transition.

Additionally, ease of maintenance and reliability are factors that should not be overlooked. Machines designed with modular components allow for quicker repairs and lower downtime, enhancing overall operational efficiency. Industry experts suggest that minimizing maintenance requirements can lead to increased production time and better resource allocation. Careful consideration of these key features will help manufacturers invest in the right fiber mixing machines tailored to their specific needs, ultimately enhancing their competitive edge in the market.

| Machine Model | Mixing Capacity (kg/h) | Power Consumption (kW) | Weight (kg) | Features |

|---|---|---|---|---|

| Model A | 500 | 15 | 1200 | Continuous mixing, adjustable speed |

| Model B | 400 | 10 | 950 | High efficiency, compact design |

| Model C | 600 | 20 | 1500 | Multi-purpose capabilities, user-friendly interface |

| Model D | 450 | 12 | 1100 | Flexible operation, low maintenance |

| Model E | 550 | 18 | 1400 | High mixing precision, energy-saving |

| Model F | 700 | 25 | 1600 | Advanced control systems, automated processes |

| Model G | 500 | 14 | 1150 | High durability, safe operation features |

| Model H | 300 | 9 | 850 | Lightweight, portable |

| Model I | 800 | 30 | 1800 | Smart integration, flexible designs |

| Model J | 650 | 22 | 1700 | Efficient performance, noise reduction technology |

In 2025, the fiber mixing machine industry is projected to undergo significant advancements, driven by innovative technologies that enhance efficiency and sustainability. According to a recent report by the International Fiber Machinery Association, the market for fiber Mixing Equipment is expected to grow at a compound annual growth rate (CAGR) of 7.5%, indicating a robust demand for cutting-edge solutions. One of the key innovations is the integration of artificial intelligence (AI) and machine learning algorithms, which enable real-time monitoring and adjustment of mixing processes. These technologies help in reducing material waste, optimizing energy consumption, and maintaining consistent quality, thereby setting a new standard in fiber processing.

Moreover, automation is becoming increasingly prevalent in fiber mixing systems. Advanced robotics are now capable of handling bulk materials with precision and speed, effectively minimizing human intervention. This shift not only enhances operational efficiency but also contributes to workplace safety. Industry studies have shown that companies implementing automated fiber mixing technologies have reported up to a 30% increase in productivity. Additionally, sustainable practices such as the use of recycled fibers and eco-friendly materials are becoming integral to the design of new machines, reflecting the industry's commitment to environmentally responsible manufacturing methods. As we look to 2025, these advancements will play a crucial role in shaping the future of fiber mixing technologies.

When exploring the optimal fiber mixing machines for 2025, it’s essential to focus on the advancements that enhance productivity and efficiency in manufacturing processes. Recent industry reports suggest that demand for high-performance fiber mixing machines will see a significant uptick, driven by innovations in automation and material science. For instance, the global fiber mixing machine market is projected to grow at a CAGR of 6.2% from 2023 to 2028, reflecting the increasing need for versatile equipment capable of handling diverse materials with precision.

Investing in new technology can drastically improve your production capabilities. Many of the best fiber mixing machines feature automated controls that allow for more consistent blending and reduced waste. Additionally, machines equipped with advanced sensors and data analytics capabilities can provide real-time feedback, ensuring optimal performance and minimizing downtime. According to the latest studies, facilities that implement high-tech fiber mixing solutions report up to a 25% increase in efficiency.

Tip: When choosing a fiber mixing machine, consider not only the initial cost but also the long-term operational savings. Look for machines that offer maintenance programs and have a good track record of durable performance. Moreover, read reviews and user experiences to gain insights into the real-world effectiveness of the machines you’re considering—this can be invaluable in making a well-informed decision.

In 2025, the landscape of fiber mixing machines is set to evolve significantly, driven by advancements in technology and increasing demands for efficiency. When evaluating these machines, a comparative analysis of performance metrics is essential. Key metrics include blending efficiency, energy consumption, durability, and maintenance requirements, which collectively determine a machine's overall effectiveness in various operational settings.

Blending efficiency is a critical metric, indicating how thoroughly and evenly different fiber types can be mixed. Machines that excel in this area often incorporate sophisticated mixing mechanisms that ensure uniform distribution of fibers, which is essential for maintaining product quality. Additionally, energy consumption is a crucial consideration; machines that utilize innovative power-saving technologies can reduce operational costs while promoting sustainability. Durability and maintenance requirements also play vital roles; machines designed with robust materials and user-friendly maintenance protocols tend to have longer lifespans and lower downtime, enhancing productivity in manufacturing environments.

As industry priorities shift towards eco-friendly practices and cost-effectiveness, understanding these performance metrics will equip operators with the knowledge to select the most suitable fiber mixing machines for their needs in 2025. This nuanced approach to machine evaluation will foster improved operational efficiency and product quality in the fiber processing sector.

This chart represents the comparative analysis of the performance metrics of the top 10 fiber mixing machines in 2025, focusing on efficiency and throughput rates.

Proper maintenance of fiber mixing machines is crucial for ensuring optimal performance and longevity. According to a 2023 industry report from the Textile Machinery Manufacturers Association, routine maintenance can enhance machine efficiency by up to 30%. Regular inspection and cleaning of components such as rollers, hoppers, and mixing chambers can prevent build-up of materials that may lead to inefficiencies or mechanical failures. It's recommended that operators establish a strict schedule for maintenance tasks, which should include lubrication of moving parts, replacement of worn-out components, and calibration checks.

Additionally, training personnel on the correct operational procedures and maintenance techniques can significantly reduce downtime. A study presented at the International Textile Machinery Conference indicated that well-trained staff can decrease machine-related errors by nearly 25%. It is vital to utilize quality spare parts and adhere to the manufacturer's guidelines for replacement intervals to keep machines operating at their best. Furthermore, implementing condition monitoring technology can provide real-time data on machine performance, enabling proactive maintenance strategies that avoid costly repairs and production halts. By prioritizing these maintenance practices, manufacturers can maximize productivity and maintain a competitive edge in the fiber mixing sector.

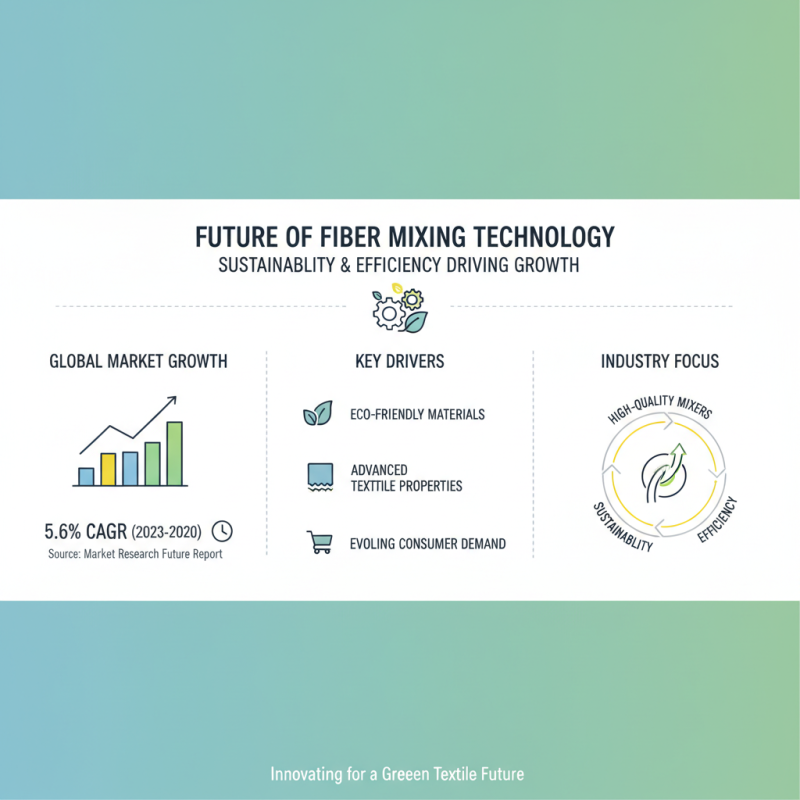

The future of fiber mixing technology is poised for significant advancements as the textile industry increasingly focuses on sustainability and efficiency. According to a report by Market Research Future, the global fiber mixing machine market is projected to grow at a compound annual growth rate (CAGR) of 5.6% from 2023 to 2030. This growth can be attributed to the rising demand for high-quality mixed fibers that meet the evolving consumer preferences for both eco-friendly materials and advanced textile properties.

One of the key trends shaping the future of fiber mixing technology is the integration of automation and AI-driven processes. These technologies enhance precision in fiber blending, allowing manufacturers to achieve consistent quality while reducing waste. A report from Grand View Research indicates that automated fiber mixing machines could increase production efficiency by more than 30%, significantly lowering operational costs. Furthermore, the increasing emphasis on recycling and the use of biodegradable fibers are set to revolutionize mixing techniques, propelling further innovations in machine design and functionality. As a result, stakeholders in the textile industry should prepare for these transformative changes, which will redefine the capabilities and applications of fiber mixing machines in the coming years.

In the quest to enhance manufacturing efficiency, the HEP-SYLW series drying and blending machine emerges as a pivotal solution tailored for industries grappling with moisture retention and clumping in their final products. Built upon the foundational SYLW series ribbon mixer, this machine introduces an innovative far-infrared ceramic heating jacket, facilitating in-depth drying of materials that tend to retain moisture during the final mixing process. This advancement ensures not only thorough drying but also a homogeneous mixing environment, enabling manufacturers to achieve consistent product quality.

Current market trends reveal that standard blending equipment typically accommodates batch sizes ranging from 10 to 15 tons. However, the HEP-SYLW series redefines these limits, boasting the capacity to process single batches of up to 40 tons. This significant enhancement allows for higher efficiency and productivity, addressing the needs of manufacturers who require rapid and effective mixing solutions. By optimizing both the drying and blending stages, this machine contributes to a streamlined production workflow, ultimately benefiting the end product quality and operational speed, marking a substantial leap forward in manufacturing performance.

: Fiber mixing machines are essential for efficiently blending different fiber types to create uniform and high-quality textile products.

The global demand for fiber mixing machines is projected to grow due to advancements in manufacturing processes and increasing customization needs in fiber production.

These machines optimize the use of raw materials, reduce waste, and improve sustainability practices in the manufacturing process.

Innovations such as artificial intelligence, machine learning algorithms, and advanced automation are anticipated to enhance efficiency and sustainability in fiber mixing.

Automation minimizes human intervention, enhances operational efficiency, increases productivity, and contributes to workplace safety.

High-performance machines offer automated controls for consistent blending, advanced sensors for real-time feedback, and can lead to significant efficiency improvements.

Buyers should consider initial costs, long-term operational savings, maintenance programs, durability, and user reviews to make informed decisions.

New technologies can provide up to a 25% increase in efficiency by enabling more consistent blending and minimizing downtime through real-time analytics.

The shift towards functional and performance-driven textiles increases the demand for fibers that can be blended to create unique properties in fabrics.

The market for fiber mixing machines is projected to grow at a CAGR of 6.2% from 2023 to 2028, indicating a robust demand for advanced equipment.

The article "Top 10 Fiber Mixing Machines in 2025: What You Need to Know" provides a comprehensive overview of fiber mixing machines, highlighting their significance in various applications. It discusses the essential features to consider when selecting a fiber mixing machine, ensuring users can make informed decisions. The article also explores the latest innovative technologies set to revolutionize fiber mixing by 2025, along with a detailed review of the best machines available in the market.

Furthermore, it offers a comparative analysis of the performance metrics of different fiber mixing machines, which aids in understanding their efficiency and effectiveness. Maintenance tips for optimal performance are included, ensuring longevity and reliability of the machines. Lastly, the article looks ahead at future trends in fiber mixing technology, giving readers insights into what advancements to expect in the coming years.