In today’s fast-moving industrial world, having efficient mixing solutions is more important than ever. The right Water Mixer Machine can really make a difference in the quality of your production. I came across a report from MarketsandMarkets that predicts the global market for mixing equipment will hit around $5.6 billion by 2026 — that’s a lot, and it’s mainly driven by increasing demand across different sectors.

Water Mixer Machines are pretty versatile and are used in all kinds of industries, from food production to chemical manufacturing. They play a key role in making sure everything mixes evenly, which helps improve what you end up with. But here’s the thing — not all machines perform the same. Their design and tech can really vary, and some models might not be the best fit for certain applications, which can lead to inconsistent results.

As industries grow and change, so does the need for better, more advanced mixing solutions. Companies like Schenck Process and A&B Process Systems are out there pushing innovation to keep up. Still, there’s always room for improvement. When choosing a Water Mixer Machine, it’s really important for users to weigh their options carefully and find one that fits their specific needs. Finding the perfect balance between efficiency and effectiveness is a challenge, but definitely doable with the right info and a bit of patience.

Water mixer machines play a crucial role in various industries, such as construction and food processing. These machines ensure that different liquids blend effectively, achieving desired consistency and quality. Consistent mixing enhances the final product and increases efficiency. Many industries depend on these machines for creating uniform solutions.

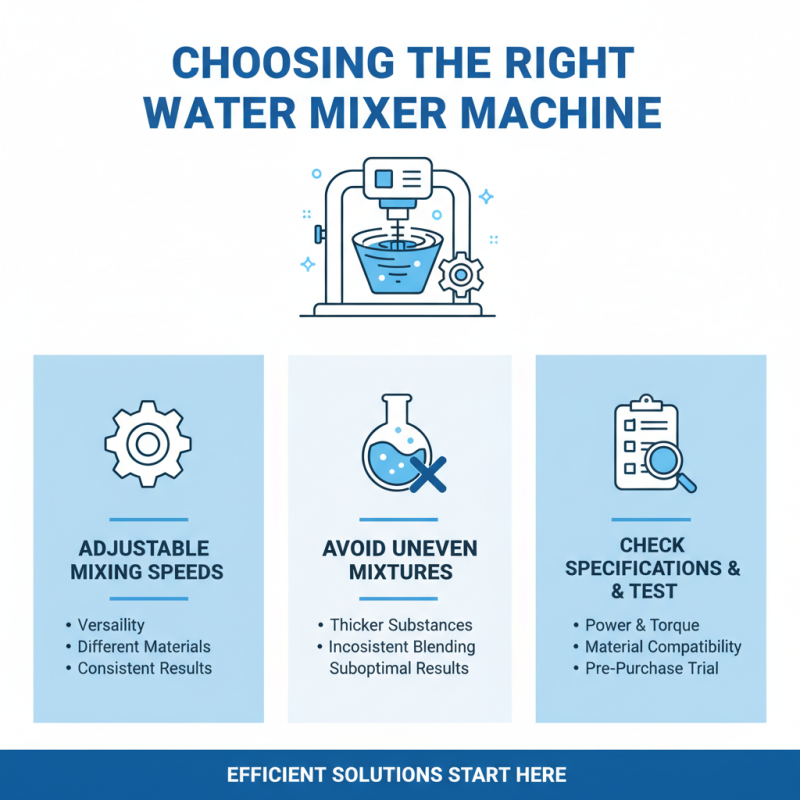

However, not all Mixing Machines are created equal. Some may struggle to blend thicker mixtures or large volumes efficiently. Users often find themselves frustrated when machines fail to meet their needs. It's essential to choose a water mixer carefully, considering factors likecapacity and mixing speed. Regular maintenance is also necessary, as wear and tear can lead to inconsistent results. Reflecting on past experiences can guide better choices in selecting the right mixer for specific applications.

When choosing a water mixer machine, several key features come into play. The size of the mixer is crucial. A larger mixer might save time. But it could also take up too much space. Think about where you'll use it. The capacity is another vital factor. Mixing small batches often needs less capacity. Larger projects require more. Finding the right balance is essential.

The type of mixing blades impacts efficiency. Different designs serve various purposes. Some blades are better for thick mixtures. Others work best with liquids. Understanding your mixing requirements helps in making the right choice. Speed settings can be helpful too. Adjustable speeds allow you to tackle different mixing tasks.

Don’t forget about the ease of cleaning. Some models have complex designs. Cleaning can become a chore if it’s too difficult. Look for features that make maintenance simple. It is important to optimize your investment, ensuring you won’t have difficulties later. Making the wrong choice could lead to frustration over time.

When considering efficient mixing solutions, a variety of water mixer machines come into play. These machines are crucial in industries such as construction, food processing, and chemical manufacturing. Recent data reveals that approximately 30% of mixing inefficiencies stem from outdated technology and improper machine selection. An effective mixer can drastically improve consistency and reduce waste, fostering better product outcomes.

The core of selecting a water mixer lies in understanding its features. Parameters like mixing speed, capacity, and energy consumption are vital. Reports indicate that mixers with variable speed settings can save up to 25% energy compared to fixed-speed machines. Operators often overlook the importance of maintenance, which is essential for performance longevity. Regularly servicing these machines can enhance their efficiency.

Many professionals underestimate their specific mixing needs. This can lead to mismatches in machine selection. For example, a mixer with too high a capacity may waste energy. Conversely, a machine that is too small may not meet production demands, leading to productivity losses. Evaluating each mixer against precise operational requirements is vital in optimizing performance.

When it comes to mixing solutions efficiently, choosing the right water mixer machine is crucial. These devices are designed to provide consistent results for various applications. You need to look for machines that offer adjustable mixing speeds. This feature allows for versatility across different materials. Some mixers may struggle with thicker substances, causing uneven mixtures. Pay attention to the specifications and test them before committing.

Cleaning and maintenance are often overlooked but essential. A machine covered in residue can affect the quality of your mixes. Regular cleaning can prolong the machine's lifespan. Also, ensure that the parts are easy to access. Difficult-to-reach areas may lead to buildup and potential malfunction. Inspect the machine's manual to understand its cleaning needs better.

Here’s a tip: always consider the capacity of the machine. If you're mixing small batches, a compact mixer may be sufficient. However, larger projects might require something more robust. Evaluate how often you'll be using the machine. A higher frequency of use may justify investing in a higher-end model. This reflection could save you both time and money in the long run.

Modern water mixer machines are changing the landscape of fluid mixing. They utilize innovative technologies that enhance efficiency and precision. According to a recent industry report, advanced mixers can reduce mixing time by 30% while ensuring consistent results. These technologies include features like automated controls and real-time monitoring.

In the realm of efficiency, water mixers can save energy. Some studies suggest that cutting-edge machines operate at up to 90% reduced energy consumption compared to older models. However, the initial investment in these machines can be substantial. This cost may deter some businesses from upgrading.

Tip: Conduct a cost-benefit analysis. Assess the long-term savings versus initial costs.

Moreover, it's essential to consider the maintenance of these machines. High-tech mixers might require specialized knowledge for proper upkeep. Failure to maintain them can lead to inefficiencies. Thus, it’s crucial for operators to receive thorough training.

Tip: Regularly schedule maintenance checks. This can help prevent potential problems down the line.

The ongoing evolution in water mixing technology is impressive. While some aspects still need refinement, the benefits are clear. Understanding the latest innovations can lead to smarter operational decisions.

This chart represents the efficiency ratings of the top 10 water mixer machines. The ratings are based on various performance metrics evaluated systematically to determine the most effective mixing solutions in modern applications.

Water mixer machines are essential in various industries. Proper maintenance extends their lifespan and ensures efficiency. Regular cleaning is crucial. Residue can build up over time, impacting performance. Always unplug the machine before starting any cleaning.

Inspecting parts frequently is also important. Check for wear and tear in the mixer blades and seals. If you notice any damage, it is advisable to replace them immediately. A small crack can lead to bigger issues. Leaks can occur, leading to water waste.

Documentation is your friend. Keep track of maintenance activities. Note when parts were replaced or cleaned. This will help you identify patterns in wear and tear. If something seems off, consider consulting a professional. Water mixers need care and attention. This will prevent unexpected breakdowns and costly repairs later on.

Water mixer machines play a vital role in multiple industries. These machines blend water with chemicals, powders, or other liquids, producing consistent mixtures. In agriculture, they mix fertilizers with water for effective crop irrigation. This precise blending ensures that nutrients reach plants evenly, promoting better growth.

In the food industry, water mixers create uniform mixtures for sauces, soups, and beverages. Efficient mixing maintains product quality. However, achieving the right consistency can be challenging. An improper blend can alter taste and texture, leading to customer dissatisfaction. Producers must regularly evaluate their mixing processes to improve results.

Additionally, in construction, water mixers are used to combine cement, sand, and other aggregates. This mixture must be homogeneous for structural integrity. Any inconsistencies can weaken a building. Regular testing and adjusting of the mixing process are crucial for safety and quality assurance. Companies must remain flexible and adapt their methods continuously to meet industry standards.

: The product aims to enhance daily efficiency. It supports various tasks seamlessly.

Start with a clear plan. Familiarize yourself with its key features for better results.

Some users may find it complex initially. They might overlook small but important steps.

Regular practice can help. Reflect on your usage to identify areas for improvement.

Check the troubleshooting guide first. If issues persist, consider reaching out for help.

It can be challenging for new users. A gradual learning approach is advisable.

Water Mixer Machines play a crucial role in various industrial processes by ensuring efficient and uniform mixing of water with different substances. This article provides a comprehensive guide to selecting the right water mixer machine, highlighting key features to consider, such as capacity, mixing speed, and energy efficiency.

Furthermore, it presents an overview of the top 10 water mixer machines, comparing their specifications and functionalities. Detailed reviews offer insights into the best options available, while the discussion on innovative technologies showcases advancements that enhance performance and usability. Additionally, maintenance tips ensure longevity and effective operation, and the applications in different industries illustrate the versatility of water mixer machines, underscoring their importance in modern manufacturing and production processes.