Analysis and Application Value of VJ Series Technology for Vertical Ribbon Mixer

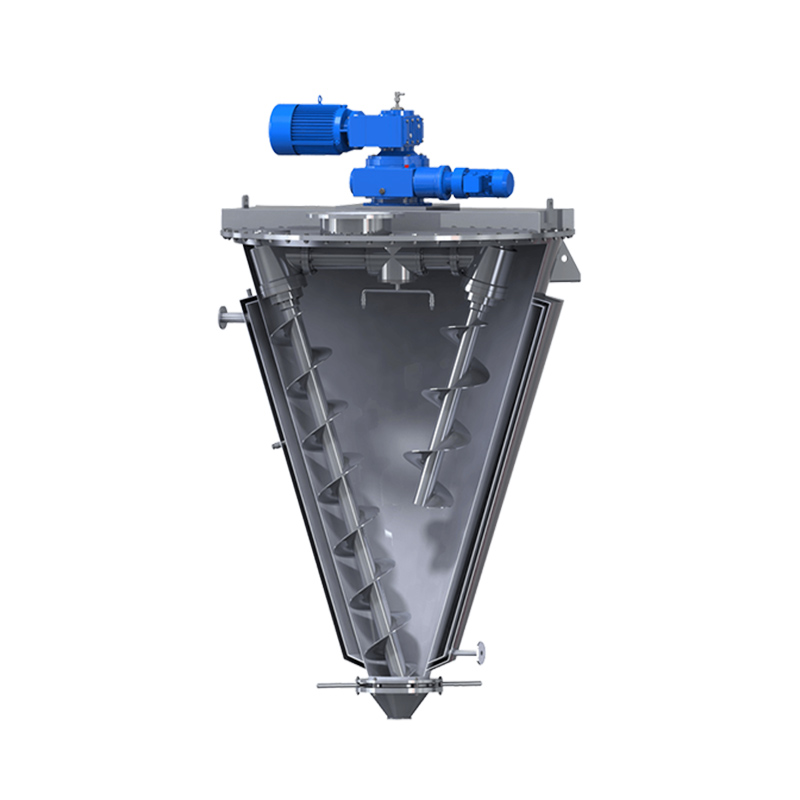

1.Core Structure and Technological Innovation

(1) Composite mixing system

By adopting a composite structure of ribbons and helical ribbons, three-dimensional convection, shear and diffusion movements are formed through the synergistic effect of double pitch conical rotor and variable diameter ribbons, achieving rapid and uniform dispersion of materials. The conical cylinder design allows the material to circulate naturally under the action of gravity, avoiding local dead corners, and achieving a mixing uniformity of over 99%.

(2) Hygiene and sealing design

There are no transmission components inside the cylinder/body, and the shaft seal and bearings are located above the working area to ensure "zero" material residue and meet food and pharmaceutical cGMP standards. The two-stage sealing technology effectively prevents oil leakage pollution and is suitable for high hygiene requirements scenarios.

(3) Energy saving and high-efficiency characteristics

By optimizing the spiral ribbons diameter and conical cylinder/body structure, the material flow resistance is reduced, and the operating speed is only 43-82 revolutions per minute, significantly reducing energy consumption compared to traditional equipment. Its low noise (≤ 75dB) and stable operating characteristics are suitable for continuous production environments.

2.Performance advantages and industry adaptability

(1) Wide material adaptability

Suitable for mixing powders+powders, powders+small amounts of liquids, and low viscosity fluids, especially adept at handling sensitive materials that are prone to agglomeration or delamination (such as polyurethane adhesive raw materials, ultrafine powders). Widely used in chemical, food, pharmaceutical, building materials and other fields, typical cases include:

Preparation of polyurethane adhesive: Avoid mechanical shear heat effects and improve product stability through Gentle Mixing;

Food ingredient mixing: meets the high hygiene standards production needs of cocoa powder, coffee ingredients, etc.

(2) Process compatibility

Optional spray device, heating interlayer or vacuum system, supporting multifunctional integration such as drying, reaction, cooling, etc. For example, in the mixing of traditional Chinese medicine extracts, no residual discharge is achieved through bottom discharge design, which complies with GMP standards.

3.Typical application scenarios and cases

(1) Chemical industry

In the polyurethane adhesive production line, replacing traditional mixing methods, the mixing time is reduced by 50%, energy consumption is reduced by 30%, and there is no material residue problem.

(2) Food industry

Used for mixing cocoa powder and flour, the conical cylinder/body design ensures uniform material flow and avoids cross contamination, and has been rated as the "best hygiene equipment" by customers.

(3) Pharmaceutical industry

In the aseptic mixing of raw materials, stainless steel 316L material and vacuum sealed structure are used to meet high cleanliness requirements and have passed FDA certification.

4.Selection suggestions and maintenance points

(1) Model selection

According to the material characteristics (such as viscosity, density) and production capacity requirements (single batch processing capacity of 6L-18m ³), VJ-K type (energy-saving type) or HP-VJ type (constant temperature type) series can be selected.

(2) Operating standards

The material filling amount should not exceed 60% -70% of the cylinder volume to avoid equipment overload;

Regularly check the wear and sealing status of the spiral ribbons to ensure long-term stable operation.

5.Summary

The VJ series cone screw Ribbon Mixer has become the preferred equipment for mixing processes in industries such as chemical, food, and pharmaceutical due to its innovative structure, high efficiency, and wide applicability. Its "zero" residual design and energy-saving characteristics not only meet the production needs of high hygiene standards, but also provide reliable guarantees for enterprises to reduce costs and increase efficiency.

Conical Screw Mixer

Conical Screw Mixer Conical Screw Belt Mixer

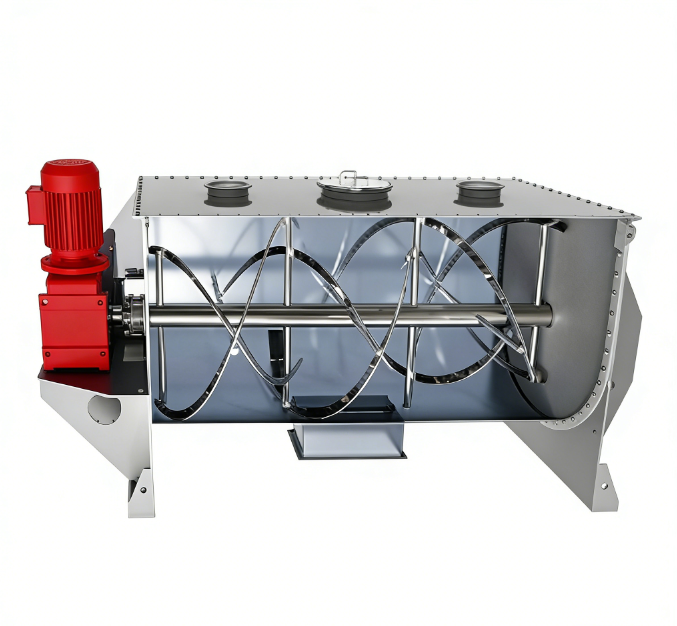

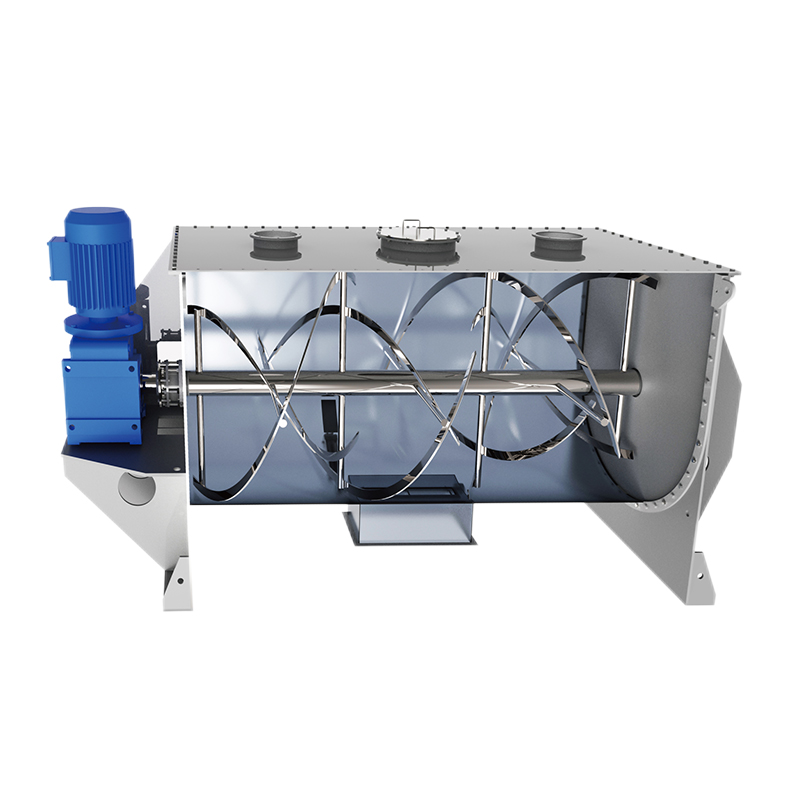

Conical Screw Belt Mixer Ribbon Blender

Ribbon Blender Plough-shear Mixer

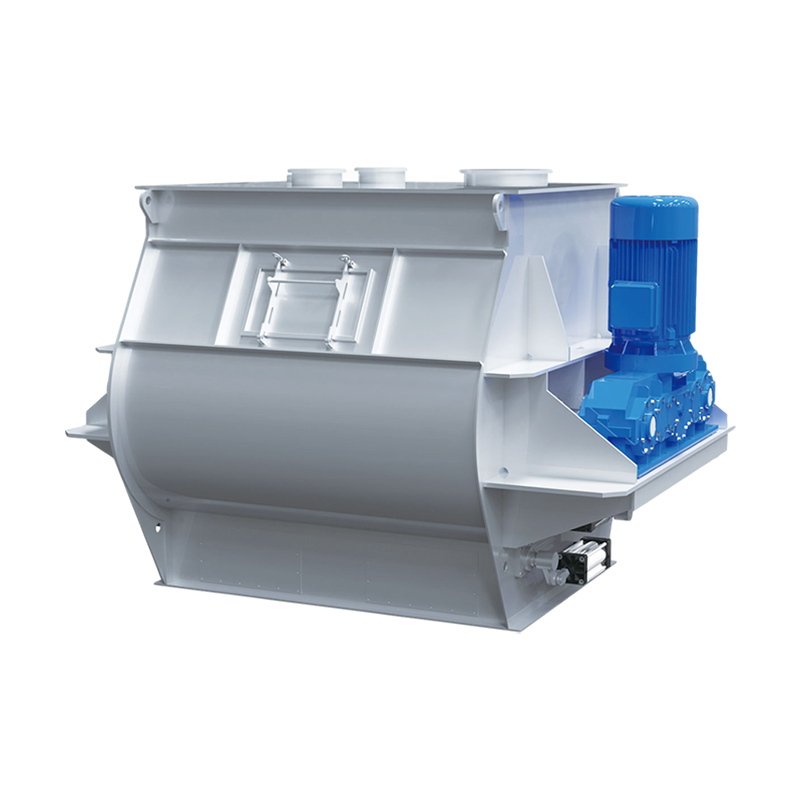

Plough-shear Mixer Double Shaft Paddle Mixer

Double Shaft Paddle Mixer CM Series Mixer

CM Series Mixer