Application Analysis of Horizontal Ribbon Mixer in the Preparation of Certain Ceramic Coating Materials

I. Application Scenarios

Based on the provided material formulation (primarily high-density zirconium silicate, supplemented with alumina and quartz) and the large-scale daily production requirement (20 tons/day), it can be determined that this mixing process is applied to the preparation of high-performance ceramic coatings for lithium end products . Specifically, it may be used for:

- Separator coating for end products : A uniform ceramic coating is formed on a polymer base membrane (such as PE/PP), which significantly improves the heat resistance, mechanical strength and electrolyte wettability of the separator.

- Electrode edge protection layer : Coated on the edge of the electrode sheet, it serves as insulation protection and prevents internal short circuits.

The coating material is directly related to the safety performance and service life of the end product , therefore, it has extremely high requirements for the uniformity, efficiency and particle integrity of the mixing.

6II. Core Advantages and Process Compatibility

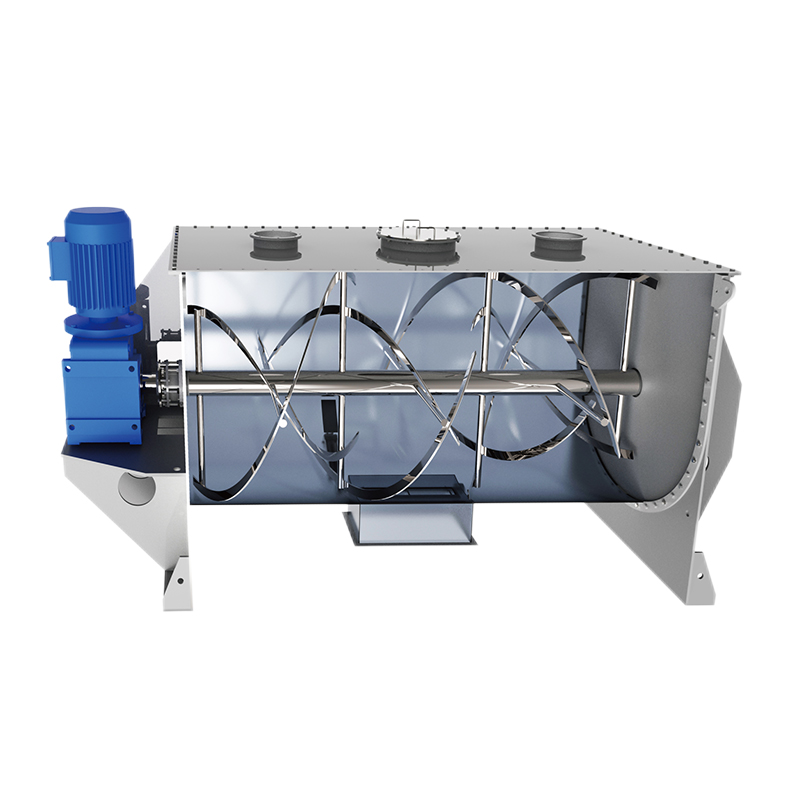

The horizontal Ribbon Mixer, with its unique working principle, perfectly meets the stringent requirements of this process, and its main advantages are:

- Excellent mixing uniformity, effectively solving density segregation.

- Processing challenges : Zirconium silicate (true density ≈ 4.7 g/cm³) and quartz (true density ≈ 2.65 g/cm³) have a significant density difference, and are very prone to separation due to gravity during mixing and settling.

- Equipment Solution : The equipment achieves simultaneous radial and axial three-dimensional convection mixing through the rotation of internal and external counter-rotating spiral ribbons . This motion mode generates powerful material circulation, effectively overcoming the separation tendency caused by density differences, and ensuring extremely high macroscopic and microscopic uniformity of each batch (300-400 kg), laying the foundation for consistent coating performance.

- Low shear mixing force, maximizing the protection of particle morphology.

- Processing challenges : The raw materials are all micron-sized fine powders (D50: 1.1-2µm), and alumina has high hardness and strong abrasiveness. High-shear mixing will destroy the original particle morphology, generate secondary fine powder, change the particle size distribution (D50, D97), and thus affect the rheology of the slurry and the coating effect.

- Equipment Solution : The horizontal ribbon mixer primarily achieves mixing through gentle volume displacement and tumbling, making it a low-shear force device. It ensures uniformity while minimizing particle breakage and wear on the equipment's working surfaces.

- High operating efficiency and residue-free unloading ensure continuous production.

- Technological challenges : A daily production capacity of 20 tons requires highly efficient equipment; at the same time, cross-contamination between batches must be prevented.

If you have any questions, please contact us:

Shanghai Shenyin Machinery (Group) Co., Ltd.

Contact Email: mike.xie@shshenyin.com - Equipment Solutions :

- Efficient mixing : For this type of dry powder mixing, the required mixing uniformity can usually be achieved within 5-15 minutes.

- Thorough unloading : Equipped with a large-opening unloading valve, it can achieve rapid and thorough emptying under the push of the screw, with virtually no residue. This not only meets the production capacity schedule but also ensures the independence of batch materials and the accuracy of the formula.

- Excellent material adaptability, possessing both dispersing and anti-agglomeration capabilities.

- Processing challenges : Fine powder materials are prone to soft agglomeration, and the quartz component has relatively poor flowability.

- Equipment Solution : The ribbon motion helps break up slight agglomerates. Optional high-speed fly knife or liquid spraying systems can be added to address potential clumping issues or to add small amounts of liquid components during the pulping stage.

III. Key Considerations for Selecting Critical Equipment

Based on the above process parameters, the following should be considered when selecting or evaluating equipment:

Volume and production capacity

Batch weight 300-400kg, daily output 20 tons

Select a model with a nominal volume of 600-800L (based on a bulk density of 1.1-1.2g/cm³ and a loading coefficient of 0.6-0.7). Calculations show that a single unit can meet the production capacity while allowing for a margin of safety.

Structural materials and wear resistance

Materials with large density differences and abrasive properties

The mixing chamber and the contact area with the helical ribbon are made of stainless steel , and the inner wall is polished with high precision . For critical wear parts (such as the helical ribbon blades), it is recommended to use a strengthening process such as overlaying wear-resistant cemented carbide .

Sealing and explosion protection

The object being processed is micron-sized fine powder.

The spindle end employs a high-efficiency gas seal or mechanical seal to prevent dust escape. The overall design must meet explosion-proof standards to ensure operational safety.

Control and cleaning

Compliant with quality management standards

Configure an automated PLC control system to support the storage and retrieval of recipes (time, speed, etc.). The equipment structure should facilitate thorough cleaning and avoid dead corners.

IV. Summary

For dry mixing processes like ceramic coating materials for end products , which have stringent requirements for uniformity, particle integrity, production efficiency, and cleanliness , horizontal ribbon mixers are the preferred solution, proven through industrial production. Through three-dimensional convection mixing, low shear, and efficient unloading, they can fully meet the quality and efficiency requirements of material preparation in end-product manufacturing.

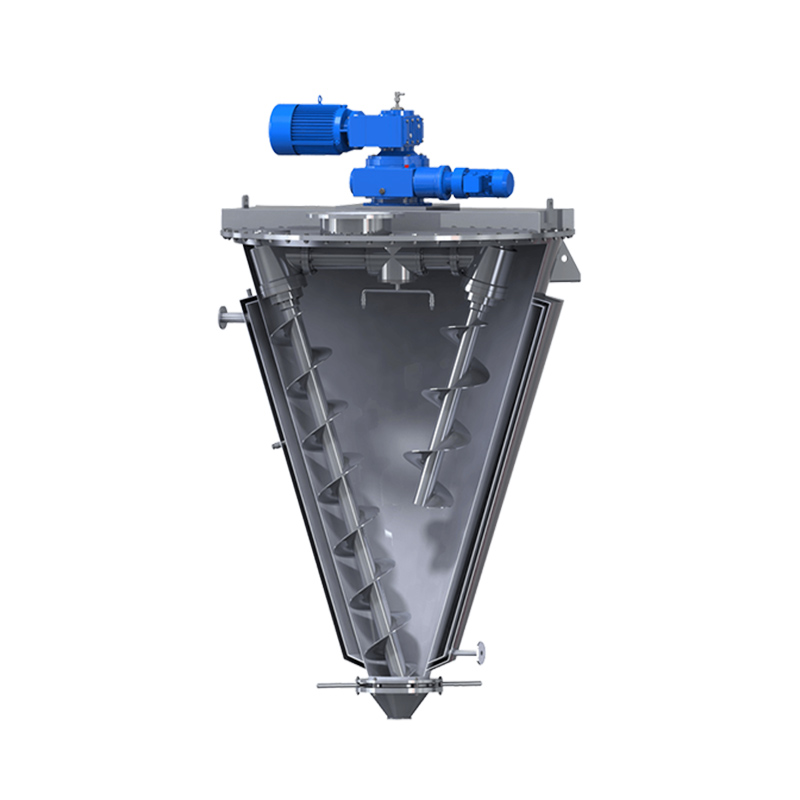

Conical Screw Mixer

Conical Screw Mixer Conical Screw Belt Mixer

Conical Screw Belt Mixer Ribbon Blender

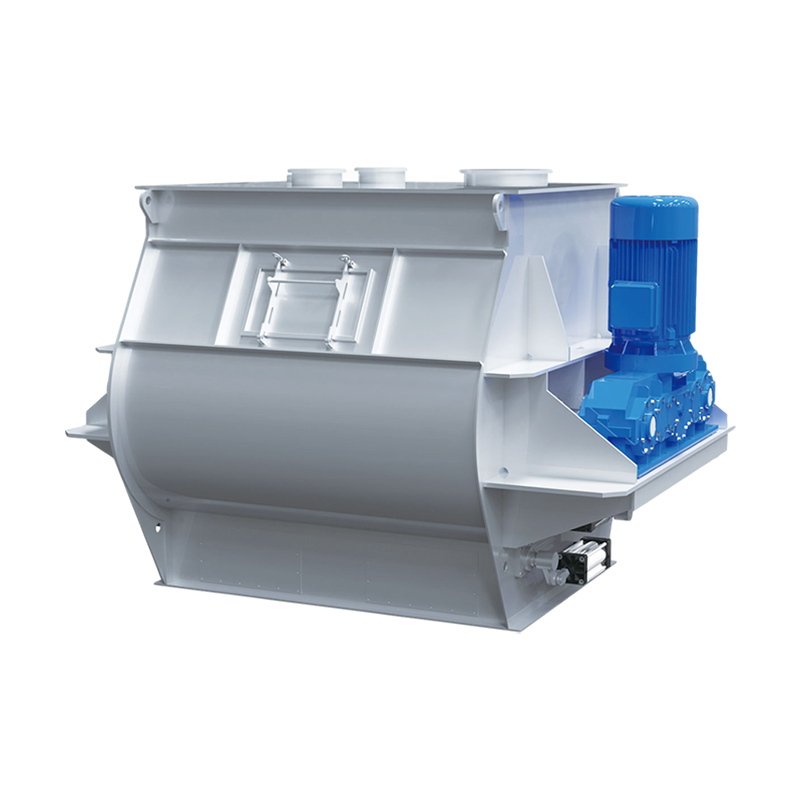

Ribbon Blender Plough-shear Mixer

Plough-shear Mixer Double Shaft Paddle Mixer

Double Shaft Paddle Mixer CM Series Mixer

CM Series Mixer