General Power-on reminder for new equipment for mixer machine

After the installation of the new equipment of mixer machine, there need some preparation before starting up. There are roughly the following types:

1. For main shaft seal of mixer machine of mechanical seal or packing seal, and shaft seals for choppers of plough Shear Mixer SYLD, it requires air supply and pressure adjustment to the appropriate range before starting up.

Pneumatic discharge valves and pneumatic feed valves require air supply and pressure adjustment to an appropriate range before starting up.

Among them, for mechanical seals with water-cooled rings, water (tap water is sufficient) needs to be added, and the inlet and outlet are divided, with the inlet at the bottom and the outlet at the top.

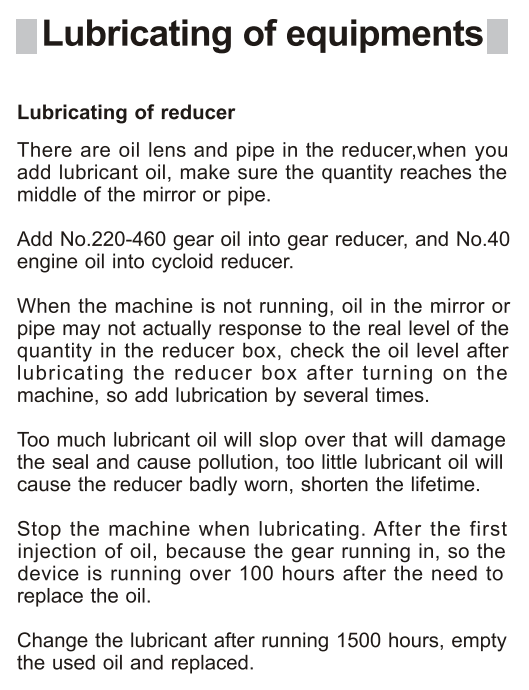

2. The reducer needs to be filled with gear oil/lubricating oil. According to the instructions, the new equipment needs to be filled with gear oil/lubricating oil in stages and batches according to the operating time.

There is a breathable cap on reducer that needs to be opened. Need to confirm the type of gear oil/lubricating oil and verify the height of the full tank.

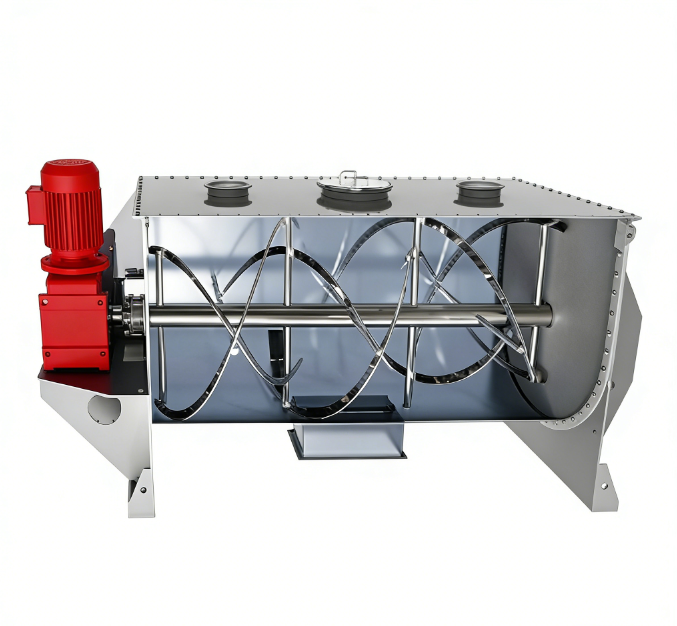

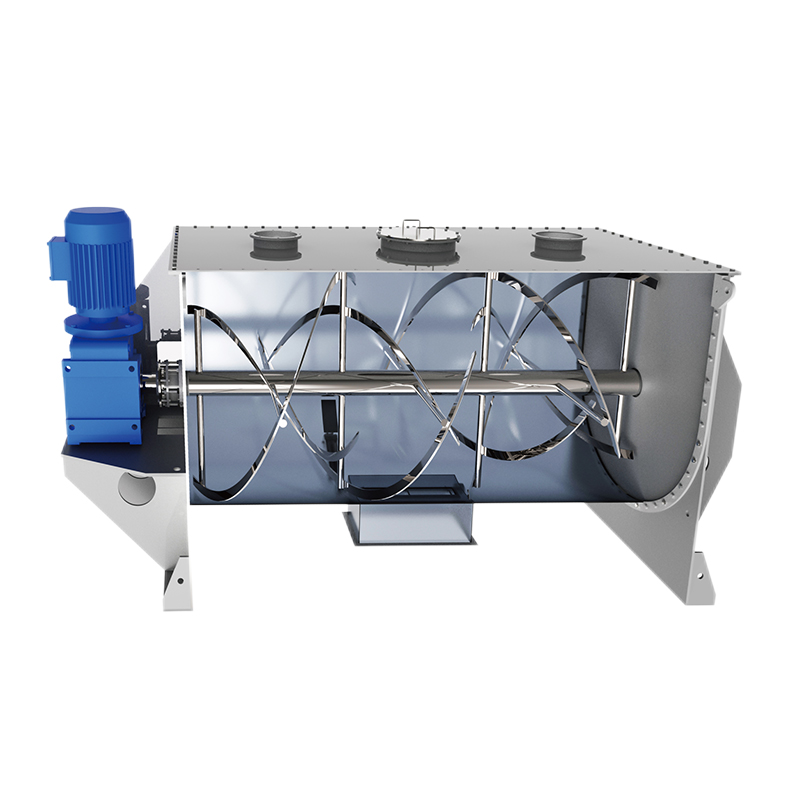

For example, the method of adding gear oil/lubricating oil to the reducer of the horizontal Ribbon Mixer SYLW is as follows:

3. If the mixer has a side cleaning door or a safety mesh on the top cover, it should be kept closed.

4. The mixer with a jacket must be equipped with an exhaust hole and need to be opened.

5. The forward and reverse sequence of the mixer operation requires manually rotating the motor to confirm the direction of operation before starting up.

The red arrow pointing in the direction of the mixer operation needs to be consistent.

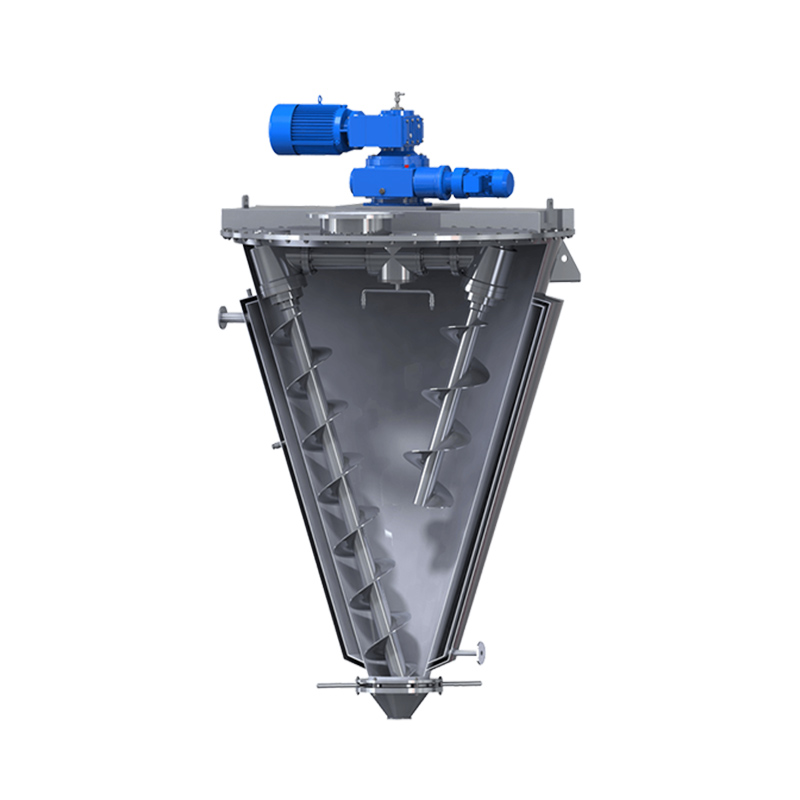

Among them, the vertical Screw Mixer A-type mixer needs to first turn on self rotation and then turn on revolution.

6. For those with a Backblowing dust collector at the top, it is necessary to connect a fan or a pressure air source.

Pulse blowback filter requires checking the sealing and confidentiality of all components connected during installation.

Conical Screw Mixer

Conical Screw Mixer Conical Screw Belt Mixer

Conical Screw Belt Mixer Ribbon Blender

Ribbon Blender Plough-shear Mixer

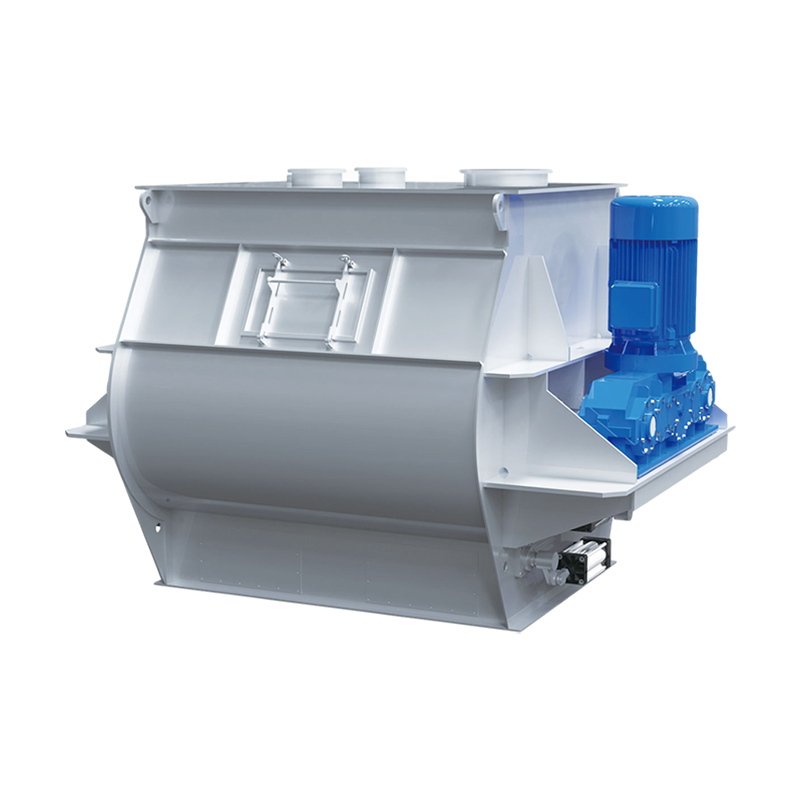

Plough-shear Mixer Double Shaft Paddle Mixer

Double Shaft Paddle Mixer CM Series Mixer

CM Series Mixer