The seventh writing: Daily maintenance of vertical screw mixer VSH

Vertical Screw Mixer VSH is a key equipment for mixing powder and granular materials, and its stable operation directly affects production efficiency and product quality.

For daily maintenance work, the key components such as the drive system, double screw parts, discharge valve, and channel steel connection parts, systematic maintenance should be carried out according to their structural functions and common failure modes. The following are the key points of sub item maintenance, compiled based on equipment principles and industry practices.

First sub item: daily maintenance of drive system

The driving part is the power source of the whole machine, mainly including motors and reducers (such as cycloidal pinwheel reducers or worm gear reducers).

1.Inspection content:

(1) The lubricating oil level of the gearbox should be maintained within the range of 1/2 to 2/3 (the standard for filling up the gearbox lubricating oil is the middle position of the oil mirror/oil gauge, and cannot exceed or be lower than the oil level). After 50 hours of full load operation of the new machine, the oil needs to be changed for the first time. After the equipment is working normally, the oil should be changed every 3-6 months and the lubricating oil level should be checked regularly. The transmission components, distribution boxes, and transmission heads inside the body/cylinder of vertical screw mixer VSH are lubricated with MOS2 (lithium based grease), which has been added before leaving the factory.

(2) Check if the bolts fixing the motor base and reducer base are loose, ensure the foundation is stable, and prevent chain jumping or transmission failure.

2. Attention:

(1) If abnormal noise or high temperature rise is found, the machine should be stopped immediately to check the meshing status of the bearings and gears.

(2) For the drive system with variable frequency control, it is also necessary to check whether the electrical parameter settings match the material characteristics.

Second sub item: daily maintenance of double screw parts(all parts inside body/cylinder)

Double screw parts(all parts inside body/cylinder) is the core component for achieving planetary Mixing Of Materials through "rotation + revolution", and its operational accuracy determines the uniformity of mixing.

1.Disassembly and Inspection Process

(1) Remove the cylinder cover and transmission connectors, and safely lift out the screw shaft.

(2) Check whether the screw blades are deformed, worn, or scratched against the cylinder wall.

(3) Check the shaft seal (oil seal) to prevent dust from overflowing or lubricating oil from contaminating the material.

2.Key Reminder

(1) During assembly, it is necessary to ensure the correct asymmetric arrangement of the two spirals and restore the original phase angle.

(2) After reinstalling, manually rotate the disc 2-3 times, confirm that there is no jamming, and then try running again.

Third sub item: daily maintenance of discharge valve

The discharge valve is located at the bottom of the cone of the vertical screw mixer, directly affecting the discharge speed and residual amount. Common forms include manual or pneumatic displacement valve/rotary valve, pneumatic knife gate valve, spherical valve, and gate valve.

1.Common problem handling

(1) If there is difficulty in rotation, the valve body clearance can be adjusted appropriately to prevent powder leakage.

(2) Check whether the seals are aging, clumping, or worn, especially the cylinder and sealing ring of the pneumatic valve.

(3) Clean the accumulated material in the valve chamber to avoid blockage caused by moisture absorption and agglomeration.

2.Optimization suggestions

(1) For high fluidity powders, powder spherical valves can be used to reduce dead corners and improve sealing performance.

(2) Pneumatic or electric actuators should be regularly tested for response speed and in place signal.

Fourth sub item: daily maintenance of channel steel connection parts

The channel steel base and connecting parts bear the weight of the entire machine and absorb operational vibrations, and long-term use is prone to looseness or cracking.

1. Key inspection points

(1) Check if the anchor bolts are loose, and if necessary, re level and tighten them.

(2) Observe whether there are cracks in the weld seam of the channel steel, especially under conditions of high vibration.

(3) Check if the connection between the equipment bracket and the ground or platform is secure to prevent displacement.

2. Maintenance suggestions

(1) It is recommended to conduct a structural integrity check once every quarter.

(2) If slight deformation or rust is found, timely welding or anti-corrosion treatment should be carried out to avoid expanding into structural faults.

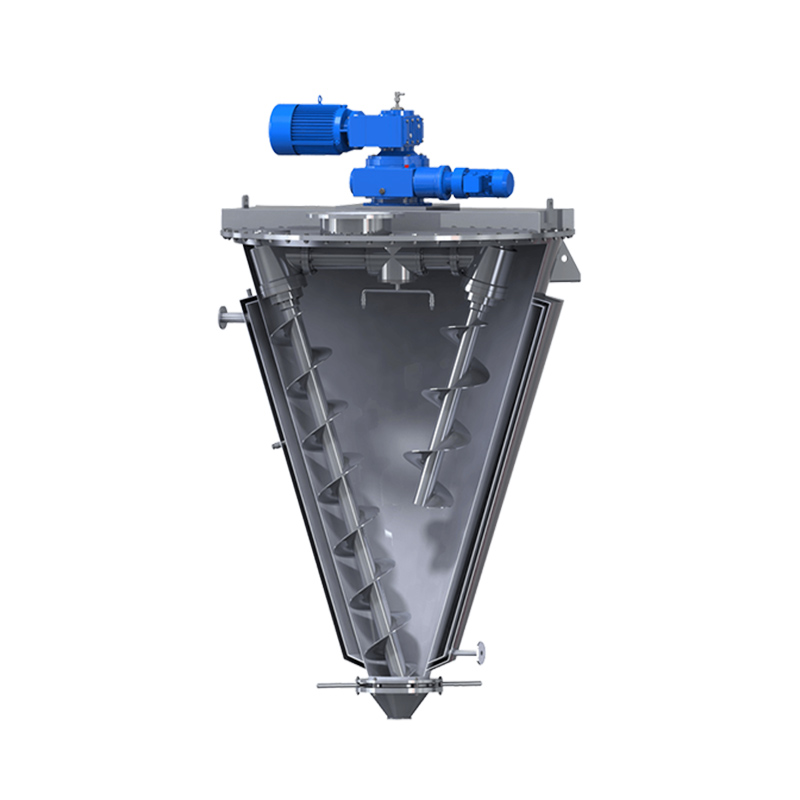

Conical Screw Mixer

Conical Screw Mixer Conical Screw Belt Mixer

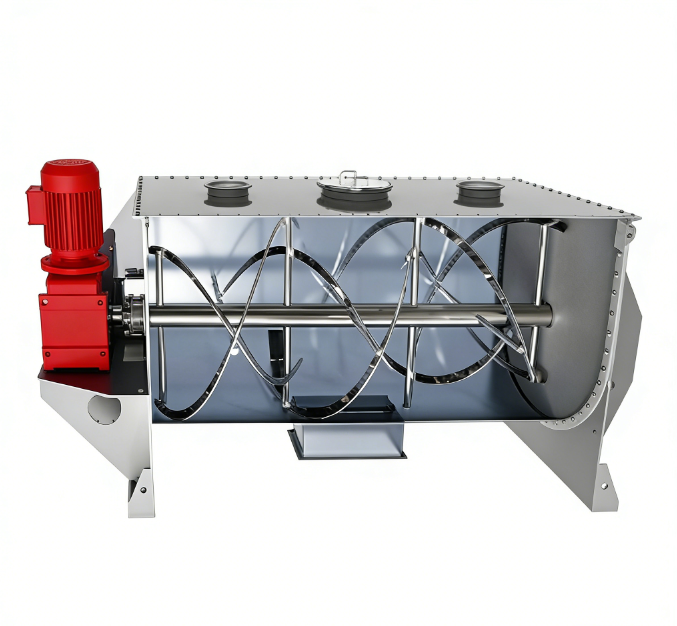

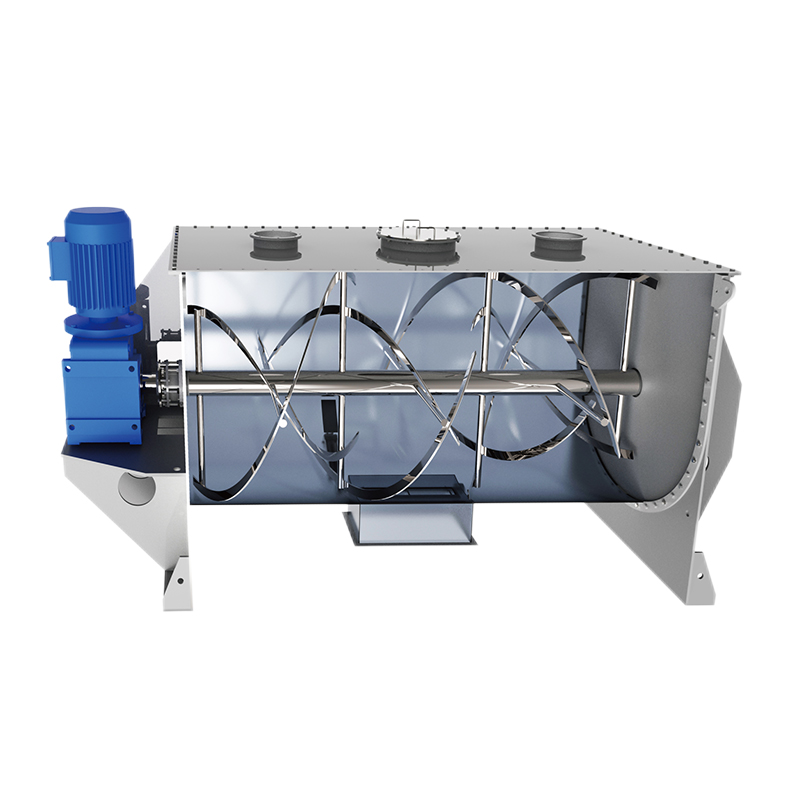

Conical Screw Belt Mixer Ribbon Blender

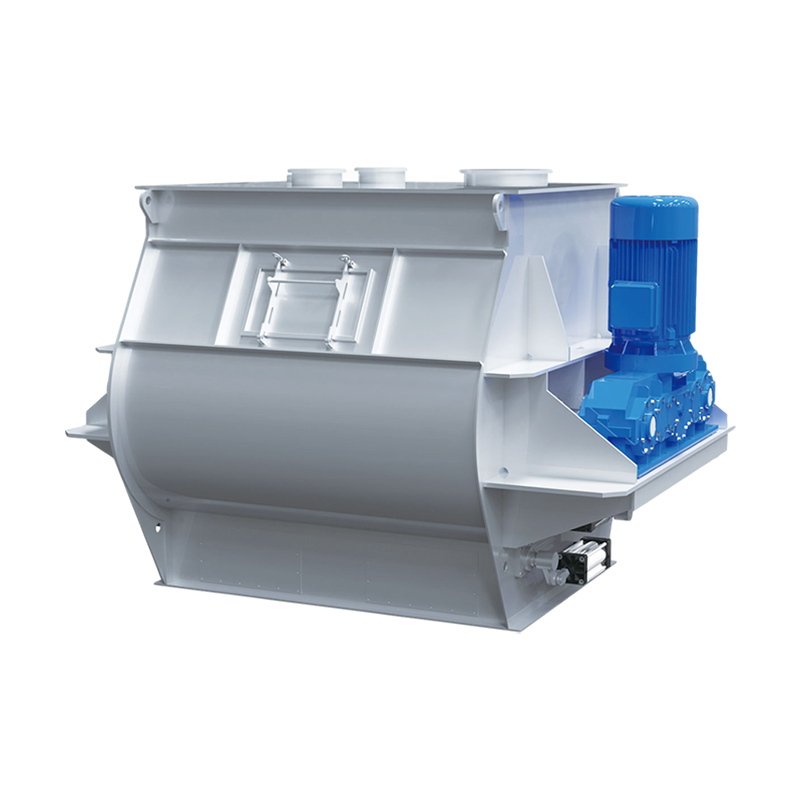

Ribbon Blender Plough-shear Mixer

Plough-shear Mixer Double Shaft Paddle Mixer

Double Shaft Paddle Mixer CM Series Mixer

CM Series Mixer