Rigorous Quality Checks on All Produced Blenders

All materials of our ShenYin Company's mixer machine undergo testing. From raw material procurement to factory production, each batch is re-inspected to ensure compliance with customer requirements, especially for lithium battery-specific mixers.

For the inspection of various raw materials in mixer machine, Shenyin adopts German original imported Spike spectrometer to carry out strict copper and zinc parts inspection on all incoming materials and purchased parts; to ensure the control of magnetic foreign matter inside and outside the barrel. Below is real photo in field:

After the production of the mixer machine is completed, there is an inspection process that involves marking and scanning for testing, Shenyin is the only powder Mixing Equipment manufacturer in the industry that introduces 3D scanning equipment, which can compare 1:1 with the 3D model after scanning the alien structure of the mixing shaft with an accuracy of up to 0.1mm. Below is real photo in field:

Detailed explanation of the material testing and inspection process for the mixer:

1.Material testing

Testing content: Material testing of the mixer machine is a key step in ensuring that the equipment meets design requirements and industry standards. The testing content includes chemical composition analysis of materials, physical property testing (such as strength, hardness, corrosion resistance), and surface quality inspection (such as cracks, deformations, or scratches). These tests ensure that the material can withstand the mechanical stress and chemical environment during the mixing process, avoiding equipment failure or material contamination.Testing methods: Common methods include spectral analysis (such as X-ray fluorescence spectrometer) for chemical composition identification, as well as hardness tester and tensile testing machine for evaluating physical properties. For corrosive materials, the corrosion resistance of stainless steel materials will be tested, while the wear resistance of carbon steel materials needs to be verified, especially when dealing with non corrosive materials such as cement mortar.Importance: Material selection directly affects the durability and applicability of the mixer. For example, stainless steel material is suitable for the pharmaceutical or food industry because it is easy to clean and meets hygiene standards; Carbon steel material is more suitable for the field of building materials, with lower cost and meeting strength requirements.

2.Inspection process after production completion

Inspection process: The inspection process is carried out after the equipment manufacturing is completed, including visual inspection, functional testing, and performance verification. Visual inspection confirms that the equipment has no manufacturing defects, such as welding defects or uneven coatings; Functional testing evaluates the operational status of motors, bearings, and transmission systems to ensure no abnormal noise or vibration; Performance validation is achieved by simulating actual mixing conditions, testing mixing uniformity and time to ensure that the design specifications are met.Marking and scanning: After passing the inspection, the equipment will be marked with a unique identifier (such as a serial number or QR code) for easy tracking and maintenance. Scanning technology, such as RFID or barcode, is used to record inspection data, including test results and parameters, which are integrated into a database to support subsequent quality control and supply chain management.

Standardized operation: Inspection follows strict SOP(Standard Operating Procedure) to ensure that each step is reproducible and auditable. For example, the operational confirmation phase verifies the stability of the equipment under no-load and load conditions, while performance confirmation simulates the actual production environment to evaluate the mixing effect and safety.

3.The role of marking and scanning

Tracking and tracing: The tagging and scanning system provides full lifecycle management for the mixer machine. The marked identifiers (such as laser engraved serial numbers) are associated with scanned data (such as inspection reports and test logs) to support rapid fault diagnosis and component replacement. This is particularly important in the pharmaceutical or food industry to ensure that equipment complies with GMP (Good Manufacturing Practice) requirements and avoids contamination risks.

Data integration: Scanning technology digitizes inspection information for easy integration into enterprise resource planning (ERP) systems. For example, QR code scanning can update device status in real-time, optimize inventory management and preventive maintenance plans from production to maintenance stages.

Quality control: Marking and scanning strengthen the quality assurance system. By recording inspection details such as material testing results and performance testing data, companies can trace equipment history to ensure that each mixer meets customer specifications and reduces the risk of returns or rework.

4.Industry application and compliance

Cross industry applicability: Blender machine are widely used in fields such as pharmaceuticals, food, building materials, and chemicals. The material testing and inspection process needs to be adapted to industry standards, such as the pharmaceutical industry emphasizing sterile and clean validation, while the building materials industry focuses on wear resistance and cost-effectiveness.

Compliance requirements: In a GMP environment, equipment design should be easy to clean and disinfect, and material selection should avoid contamination. The marking and scanning of the inspection process support compliance auditing, provide verifiable records, and ensure that the equipment complies with regulations throughout the entire process from design to delivery.

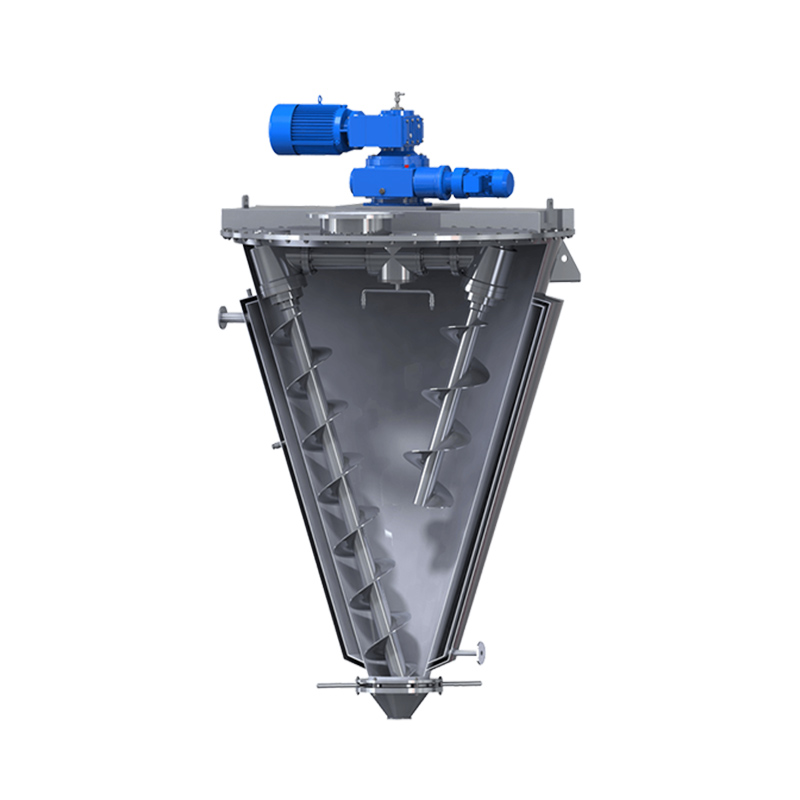

Conical Screw Mixer

Conical Screw Mixer Conical Screw Belt Mixer

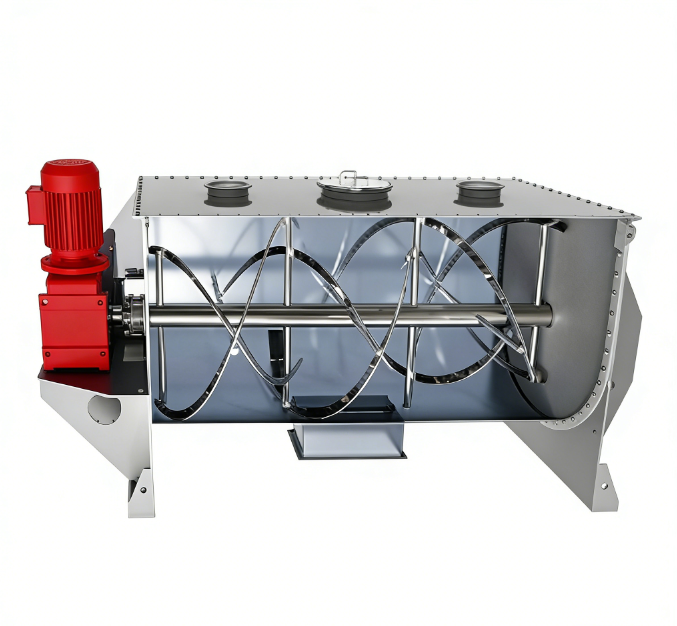

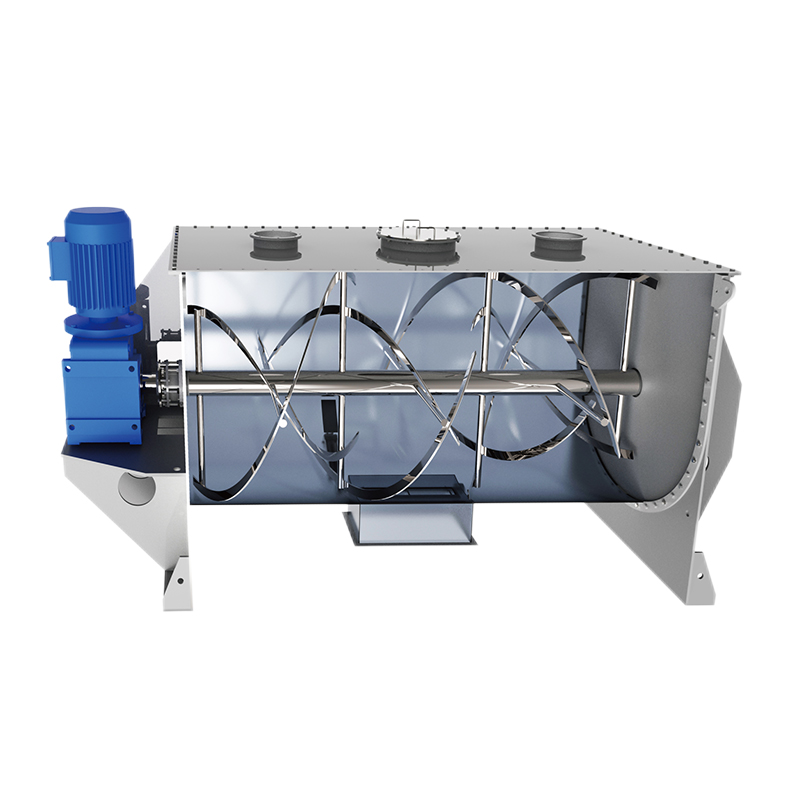

Conical Screw Belt Mixer Ribbon Blender

Ribbon Blender Plough-shear Mixer

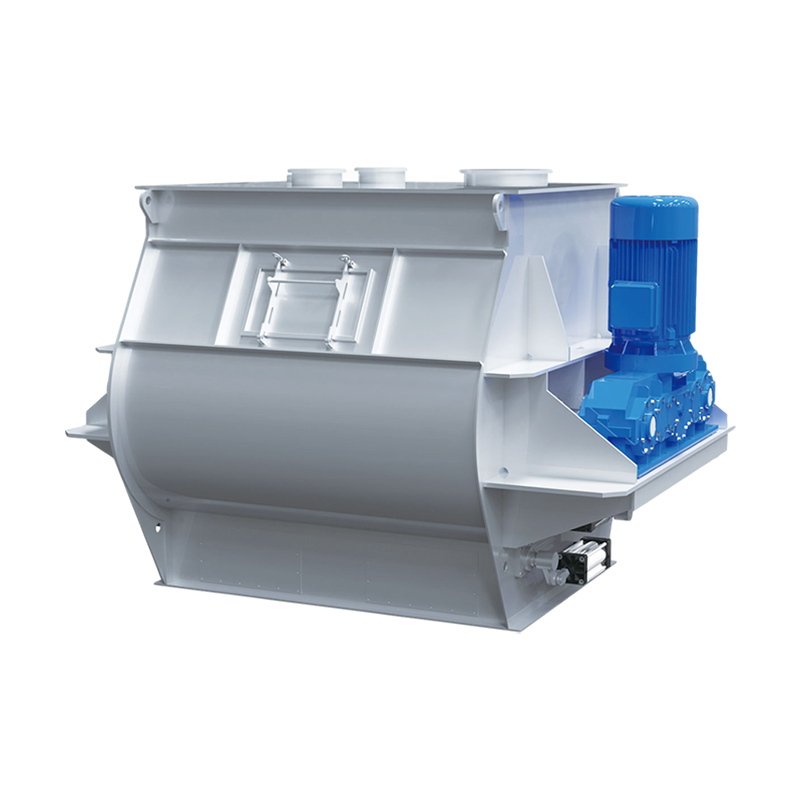

Plough-shear Mixer Double Shaft Paddle Mixer

Double Shaft Paddle Mixer CM Series Mixer

CM Series Mixer