Kev Tshawb Fawb Txog Daim Ntawv Thov ntawm Kab Rov Tav Ribbon Mixer hauv Kev Npaj Cov Khoom Siv Txheej Txheem Ceramic

I. Cov Xwm Txheej Thov

Raws li cov qauv khoom siv (feem ntau yog cov zirconium silicate uas muaj zog heev, ntxiv nrog alumina thiab quartz) thiab qhov xav tau ntau yam khoom txhua hnub (20 tons / hnub), nws tuaj yeem txiav txim siab tias cov txheej txheem sib tov no tau siv rau kev npaj cov txheej txheem ceramic ua haujlwm siab rau cov khoom kawg lithium. Tshwj xeeb, nws tuaj yeem siv rau:

●Txheej txheej cais rau cov khoom kawg: Ib txheej txheej ceramic sib xws yog tsim rau ntawm daim nyias nyias polymer (xws li PE/PP), uas ua rau qhov tiv taus cua sov, lub zog kho tshuab thiab electrolyte ntub ntawm cov cais.

●Txheej tiv thaiv ntug electrode: Txheej rau ntawm ntug ntawm daim ntawv electrode, nws ua haujlwm ua kev tiv thaiv rwb thaiv tsev thiab tiv thaiv cov voj voog luv luv sab hauv.

Cov khoom siv txheej yog ncaj qha cuam tshuam nrog kev ua haujlwm kev nyab xeeb thiab kev pabcuam lub neej ntawm cov khoom kawg, yog li ntawd, nws muaj cov kev xav tau siab heev rau kev sib xws, kev ua haujlwm zoo thiab kev ncaj ncees ntawm cov khoom sib xyaw.

6II. Cov Txiaj Ntsig Tseem Ceeb thiab Kev Sib Xws ntawm Cov Txheej Txheem

Kab rov tav Ribbon Tov Khoom, nrog nws txoj cai ua haujlwm tshwj xeeb, ua tau raws li qhov yuav tsum tau ua ntawm cov txheej txheem no, thiab nws cov txiaj ntsig tseem ceeb yog:

1. Kev sib xyaw ua ke zoo heev, daws tau qhov sib cais ceev.

● Cov teeb meem ntawm kev ua cov khoom: Zirconium silicate (qhov ceev tiag tiag ≈ 4.7 g/cm³) thiab quartz (qhov ceev tiag tiag ≈ 2.65 g/cm³) muaj qhov sib txawv ntawm qhov ceev, thiab yooj yim sib cais vim yog lub ntiajteb txawj nqus thaum sib tov thiab sib xyaw.

● Kev Dais Teeb Meem Txog Khoom Siv: Cov khoom siv no ua tiav kev sib xyaw ua ke ntawm radial thiab axial peb-dimensional convection los ntawm kev tig ntawm cov ribbons sab hauv thiab sab nraud uas tig rov qab. Hom kev txav no tsim kom muaj kev ncig ntawm cov khoom siv, kov yeej qhov kev sib cais uas tshwm sim los ntawm qhov sib txawv ntawm qhov ceev, thiab ua kom muaj kev sib npaug ntawm macroscopic thiab microscopic ntawm txhua pawg (300-400 kg), tso lub hauv paus rau kev ua haujlwm ntawm txheej txheej tas li.

2. Qis shear sib tov zog, maximizing qhov kev tiv thaiv ntawm particle morphology.

● Cov teeb meem ntawm kev ua cov khoom siv: Cov khoom siv raw yog cov hmoov me me uas muaj qhov loj me me (D50: 1.1-2µm), thiab alumina muaj qhov tawv thiab muaj zog abrasiveness. Kev sib xyaw ua ke nrog high-shear yuav rhuav tshem cov qauv qub, tsim cov hmoov me me thib ob, hloov qhov faib tawm ntawm cov khoom me me (D50, D97), thiab yog li cuam tshuam rau rheology ntawm cov slurry thiab cov nyhuv ntawm txheej.

●Kev Dais Teeb Meem Txog Khoom Siv: Lub tshuab sib tov kab rov tav feem ntau ua tiav kev sib tov los ntawm kev hloov pauv me me thiab kev sib hloov, ua rau nws yog lub cuab yeej siv zog tsawg. Nws ua kom muaj kev sib npaug thaum txo qis kev tawg thiab kev hnav ntawm cov khoom siv ua haujlwm.

3. Kev ua haujlwm zoo thiab kev tshem tawm cov khoom seem tsis muaj kev puas tsuaj ua kom muaj kev tsim khoom tas mus li.

● Cov teeb meem thev naus laus zis: Lub peev xwm tsim khoom txhua hnub ntawm 20 tons xav tau cov khoom siv ua haujlwm zoo heev; tib lub sijhawm, kev sib kis kab mob ntawm cov pawg yuav tsum tau tiv thaiv.

Yog koj muaj lus nug dab tsi, thov hu rau peb:

Shanghai Shenyin Machinery (Pawg) Co., Ltd.

Email Tiv Tauj: mike.xie@shshenyin.com

●Cov Kev Dais Teeb Meem Txog Khoom Siv:

●Kev sib tov zoo: Rau hom kev sib tov hmoov qhuav no, qhov kev sib tov sib npaug uas xav tau feem ntau tuaj yeem ua tiav hauv 5-15 feeb.

●Kev rho tawm tag nrho: Nruab nrog lub qhov qhib loj rau kev rho tawm, nws tuaj yeem ua tiav kev rho tawm sai thiab tag nrho hauv qab kev thawb ntawm lub hau ntswj, tsis muaj cov khoom seem. Qhov no tsis yog tsuas yog ua tau raws li lub sijhawm tsim khoom xwb tab sis kuj ua kom ntseeg tau tias cov khoom siv sib xyaw ua ke thiab qhov tseeb ntawm cov mis.

4. Kev hloov pauv khoom zoo heev, muaj peev xwm faib tawm thiab tiv thaiv kev sib sau ua ke.

● Cov teeb meem ntawm kev ua cov khoom: Cov khoom siv hmoov zoo yooj yim sib sau ua ke, thiab cov khoom siv quartz tsis yooj yim ntws.

●Kev Dais Teeb Meem Txog Khoom Siv: Lub zog ntawm daim kab xev pab rhuav cov khoom me me uas sib sau ua ke. Koj xaiv tau rab riam ya ceev ceev lossis cov tshuab txau kua uas siv tau los daws cov teeb meem uas yuav ua rau sib sau ua ke lossis ntxiv cov khoom me me uas ua kua thaum lub sijhawm ua pulping.

III. Cov Kev Xav Tseem Ceeb rau Kev Xaiv Cov Khoom Siv Tseem Ceeb

Raws li cov txheej txheem saum toj no, cov hauv qab no yuav tsum tau xav txog thaum xaiv lossis ntsuas cov khoom siv:

Qhov ntim thiab peev xwm tsim khoom

Qhov hnyav ntawm pawg yog 300-400kg, txhua hnub tso zis yog 20 tons

Xaiv ib lub qauv uas muaj qhov ntim tsawg kawg nkaus ntawm 600-800L (raws li qhov ceev ntawm 1.1-1.2g/cm³ thiab qhov coefficient ntawm kev thauj khoom ntawm 0.6-0.7). Cov kev xam suav qhia tau tias ib chav tsev tuaj yeem ua tau raws li lub peev xwm tsim khoom thaum tseem tso cai rau qhov kev nyab xeeb ntxiv.

Cov ntaub ntawv tsim kho thiab kev hnav tsis kam

Cov ntaub ntawv uas muaj qhov sib txawv ntawm qhov ceev thiab cov khoom siv abrasive

Lub chamber sib tov thiab thaj chaw sib cuag nrog lub helical ribbon yog ua los ntawm stainless hlau, thiab phab ntsa sab hauv yog polished nrog high precision. Rau cov khoom hnav tseem ceeb (xws li cov hniav helical ribbon), nws raug pom zoo kom siv cov txheej txheem txhawb zog xws li overlaying hnav-resistant cemented carbide.

Kev kaw thiab kev tiv thaiv tawg

Cov khoom uas raug ua tiav yog hmoov me me uas muaj qhov loj me me.

Qhov kawg ntawm lub spindle siv lub foob roj lossis lub foob kho tshuab ua haujlwm tau zoo los tiv thaiv cov hmoov av tawm. Kev tsim qauv tag nrho yuav tsum ua tau raws li cov qauv tiv thaiv kev tawg kom ntseeg tau tias muaj kev nyab xeeb hauv kev ua haujlwm.

Kev tswj thiab kev ntxuav

Ua raws li cov qauv kev tswj xyuas zoo

Teeb tsa lub tshuab tswj PLC uas tsis siv neeg los txhawb kev khaws cia thiab rov qab tau cov zaub mov txawv (lub sijhawm, qhov ceev, thiab lwm yam). Cov qauv khoom siv yuav tsum pab txhawb kev ntxuav kom huv si thiab zam cov ces kaum tuag.

IV. Kev Txheeb Xyuas

Rau cov txheej txheem sib tov qhuav xws li cov ntaub ntawv txheej ceramic rau cov khoom kawg, uas muaj cov kev cai nruj rau kev sib xws, kev ncaj ncees ntawm cov khoom me me, kev ua haujlwm zoo, thiab kev huv, cov khoom sib tov kab rov tav yog qhov kev daws teeb meem zoo tshaj plaws, ua pov thawj los ntawm kev tsim khoom lag luam. Los ntawm kev sib tov convection peb-seem, shear qis, thiab kev tshem tawm zoo, lawv tuaj yeem ua tau raws li qhov zoo thiab kev ua haujlwm ntawm kev npaj cov khoom siv hauv kev tsim khoom kawg.

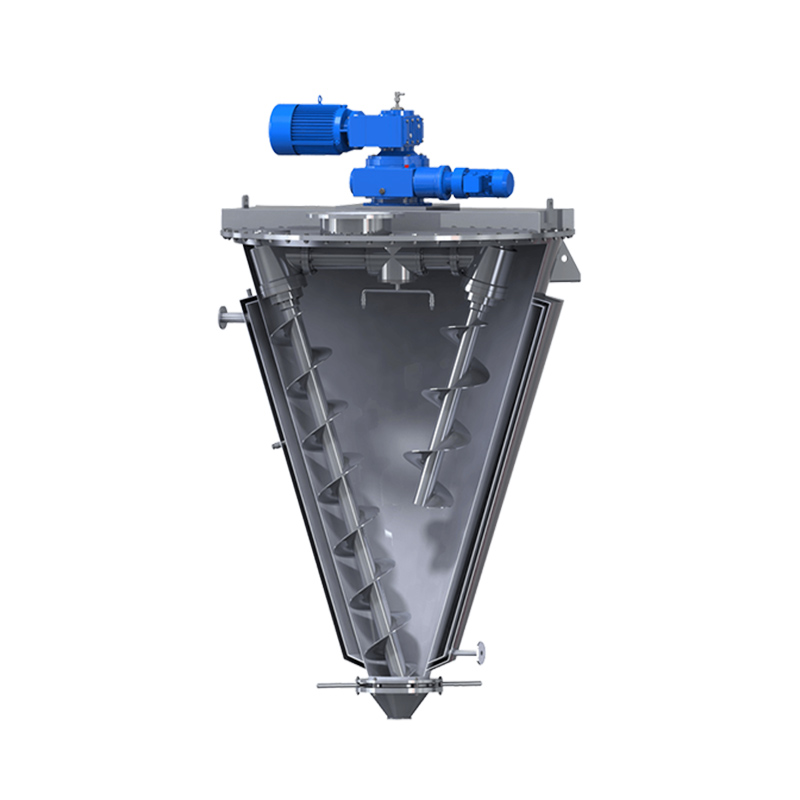

Conical Ntsia Hlau Tov Khoom

Conical Ntsia Hlau Tov Khoom Conical Ntsia Hlau Siv Tov Khoom

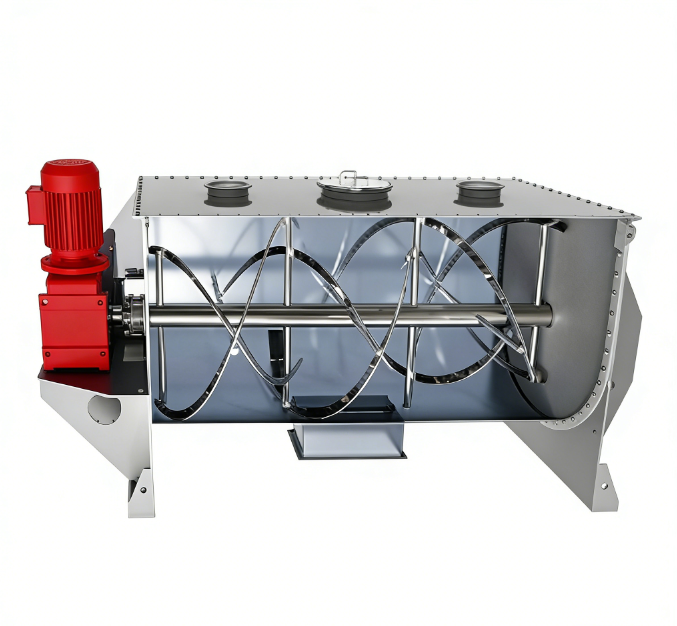

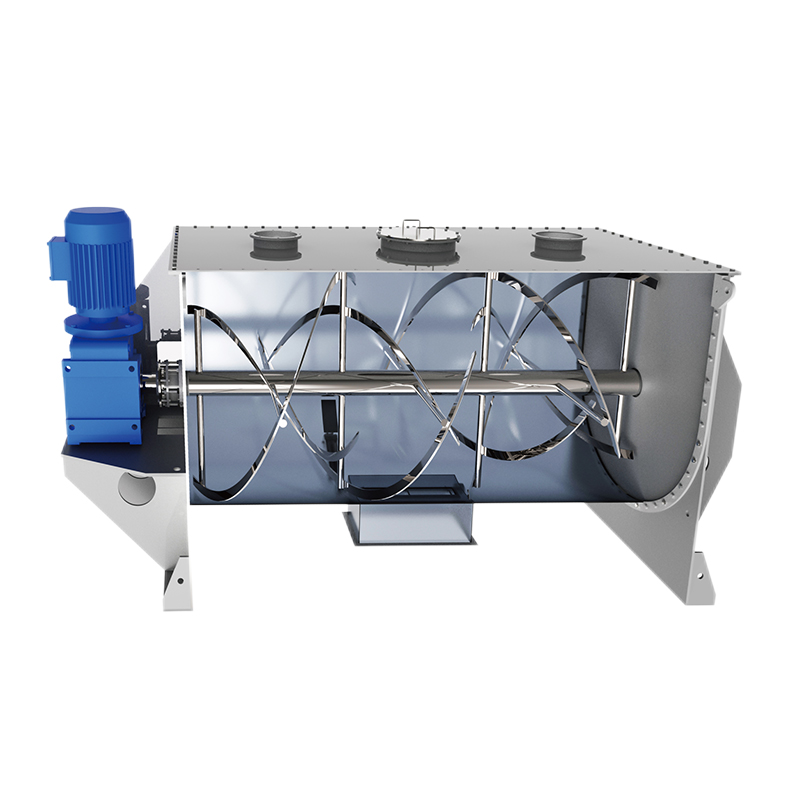

Conical Ntsia Hlau Siv Tov Khoom Ribbon Blender

Ribbon Blender Lub Tshuab Sib Tov Plough-shear

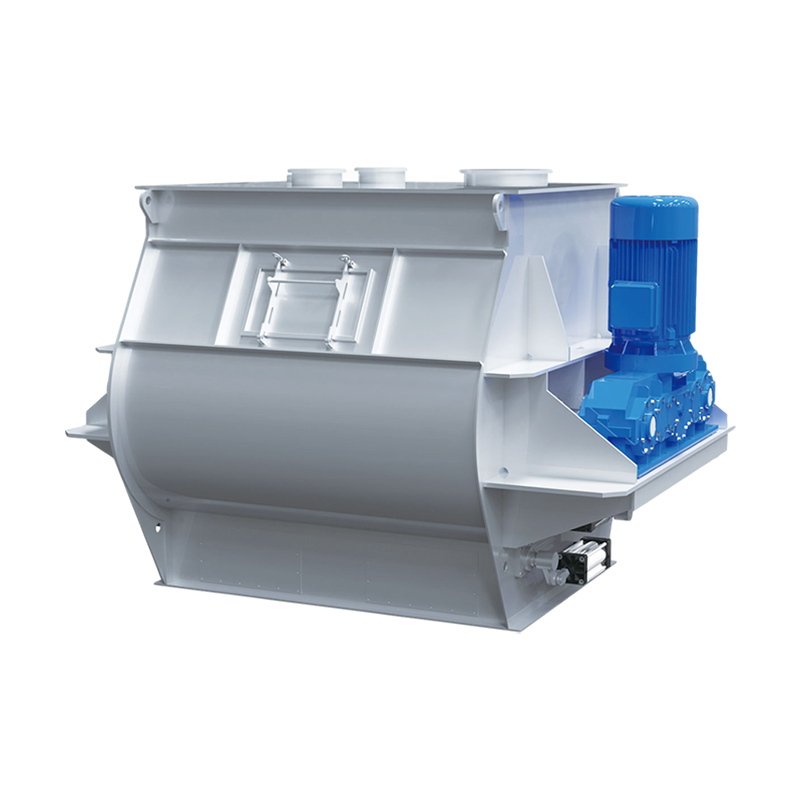

Lub Tshuab Sib Tov Plough-shear Ob Chav Ncej Paddle Tov Khoom

Ob Chav Ncej Paddle Tov Khoom CM Series Tov Khoom

CM Series Tov Khoom