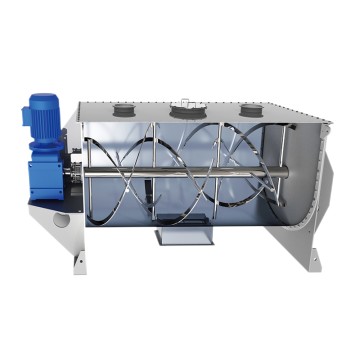

Injin haɗa kayan haɗin SYLD jerin-plough-shear wani injin haɗa kayan haɗin kwance ne na musamman wanda ya dace da haɗa kayan haɗin da sauƙin haɗawa (kamar zare ko mai sauƙin haɗawa ta hanyar danshi), haɗa kayan foda tare da ƙarancin ruwa, haɗa kayan da ba su da kyau, haɗa foda tare da haɗa ruwa mai ƙarancin ɗanko. A cikin injin haɗa spindle da mai yanke ƙugiya mai taimako, yana kammala kyakkyawan samar da haɗa kayan haɗin. Ana amfani da shi sosai a cikin yumbu, kayan da ba su da ƙarfi, kayan da ba su da juriya ga lalacewa, carbide mai siminti, ƙarin abinci, turmi mai gauraya, fasahar yin takin zamani, maganin laka, roba da filastik, sinadarai masu kashe gobara, kayan gini na musamman da sauran masana'antu.

Injin Haɗa Sukuri Mai Mazugi

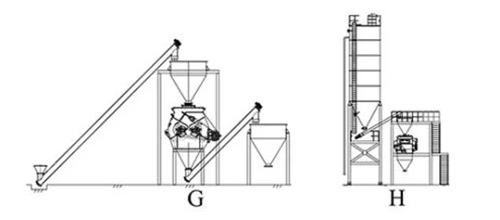

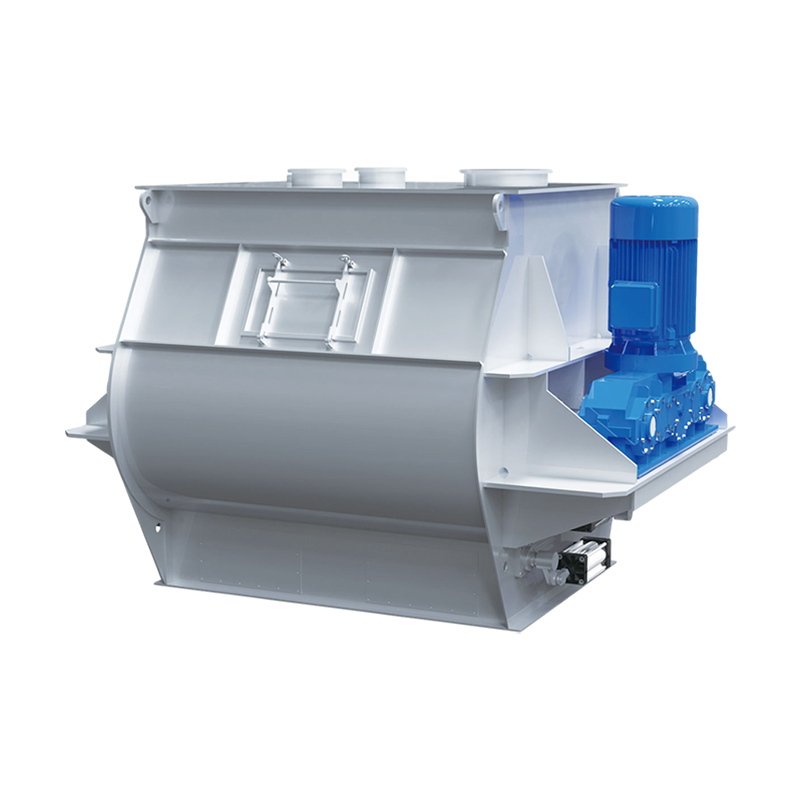

Injin Haɗa Sukuri Mai Mazugi Mazubin Mazubi Mai Zane

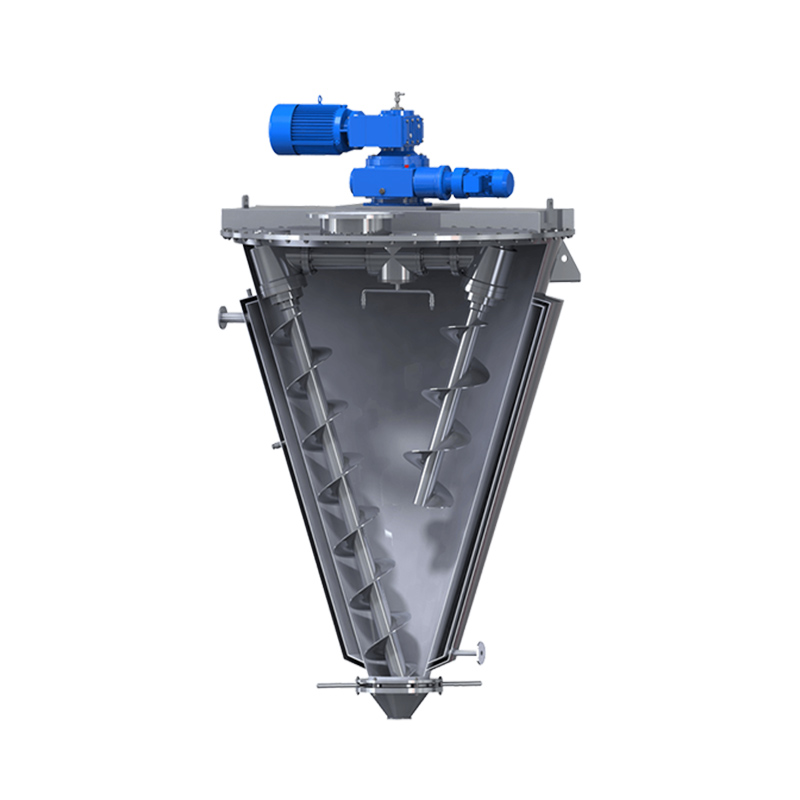

Mazubin Mazubi Mai Zane Blender ɗin Ribbon

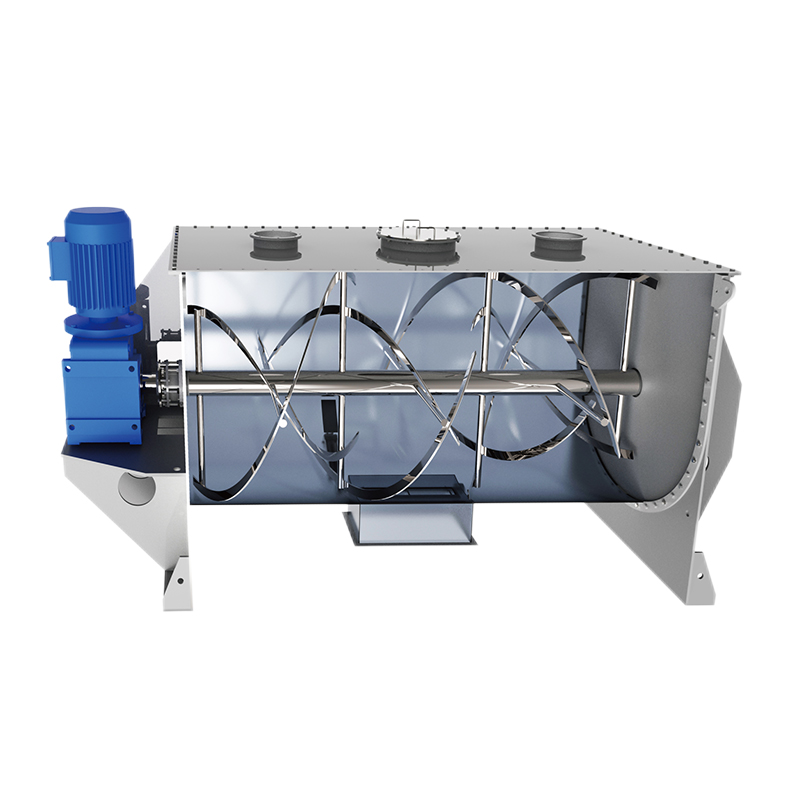

Blender ɗin Ribbon Injin haɗa garma

Injin haɗa garma Injin Haɗa Paddle Mai Shaft Biyu

Injin Haɗa Paddle Mai Shaft Biyu Mai Haɗawa na CM Series

Mai Haɗawa na CM Series